Process for refining high purifity hexanpropylamide

A refining method, high-purity technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

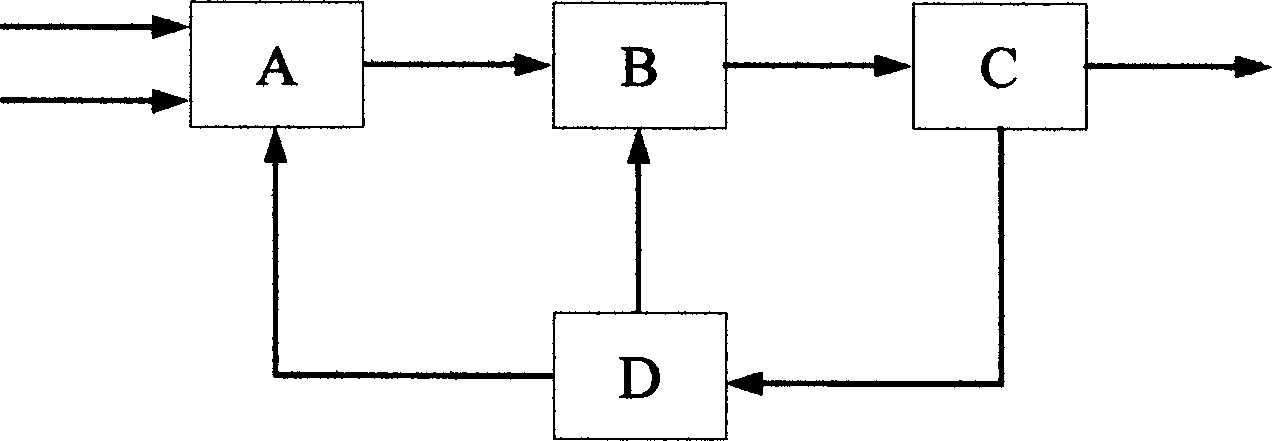

Image

Examples

Embodiment

[0026] The Beckmann rearrangement product of cyclohexanone oxime contains about 43% of caprolactam (mass percentage, the same below), about 51% of sulfuric acid, and free SO 3 About 4% and impurities 2%, its flow rate is 25.2m 3 / h, discharged into the mixer through the pump, at 37.1m 3 / h is added with 20% ammonia water for neutralization, in the separator with 7.6m 3 / h After mixing the circulating caprolactam aqueous solution, the crude caprolactam oil is separated out, and the ratio is 24.4m 3 / h flow into the extraction tower. 54.4m added to the top of the tower 3 / h of pure benzene, use 0.8m for the extraction phase 3 / h water is washed to obtain a benzene-caprolactam solution, which contains about 20.5% of caprolactam, 76.8% of benzene, 2.6% of water and 0.1% of impurities.

[0027] Benzene solution at 92.5m 3 / h flow into the three-effect distillation tower, the top of the first tower distillates 42.3m of benzene 3 / h, 18.1m of benzene distilled from the top of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com