Preparation method of humidity sensitive element humidity sensing membrane of humidity sensor

A technology of humidity sensor and humidity sensor, which is applied in the direction of instruments, alarms, material impedance, etc., can solve instability and other problems, and achieve the effects of good high humidity stability, small hysteresis, and excellent swelling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

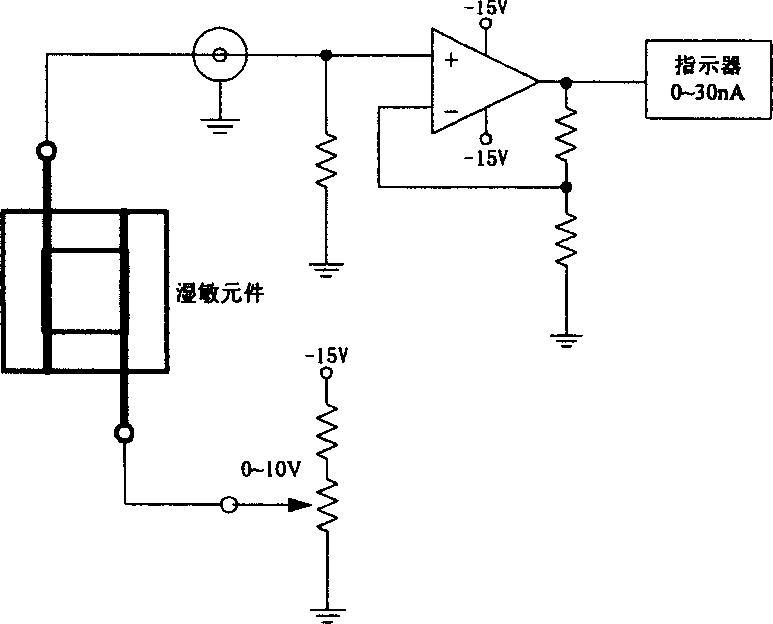

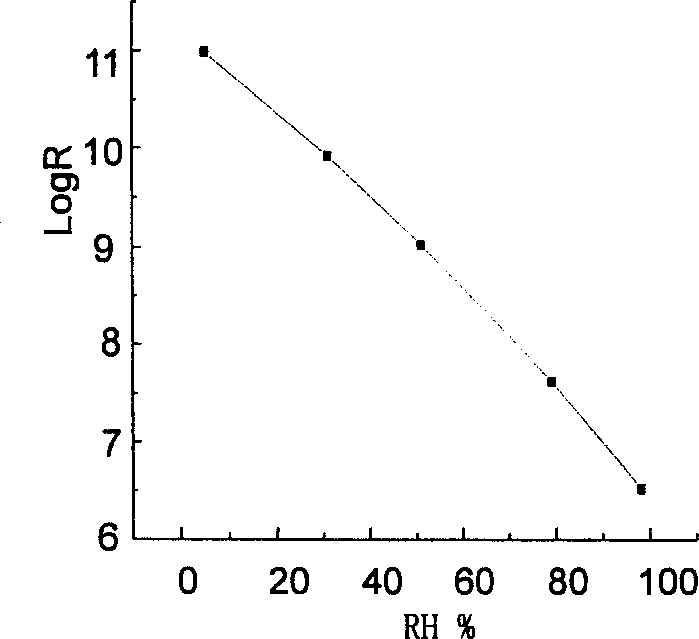

Image

Examples

Embodiment 1

[0019] The body preparation process and steps in this embodiment are as follows:

[0020] (1) First prepare a binary grafting reaction reagent system. The components and molar concentrations of the reagents in the system are:

[0021] Acrylic acid 1.8mol / L

[0022] Sodium p-styrene sulfonate 0.7mol / L;

[0023] (2) Cut the high-density polyethylene film into a 3×6cm rectangle, scrub it with acetone, and then dry it in an oven at 50°C to a constant weight; put the weighed high-density polyethylene film into the polyethylene film Fill the bag with high-purity nitrogen, squeeze it many times to drive away the remaining air; after sealing, place it on a flatbed cart for dynamic electron beam irradiation, the electron beam intensity is 3mA, and the total irradiation dose is 200kGy ;

[0024] (3) The irradiated high-density polyethylene film and the polypropylene non-woven fabric of the backing material are stacked together, and then rolled into a cylindrical shape with a glass rod as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com