Composite nanometer filtering film and its preparation method

A composite nanofiltration membrane and base membrane technology, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of mechanical strength and hydrophobicity decrease, functional coating easy to peel off, membrane function deterioration, etc. Achieve the effects of easy industrial implementation, low cost, and improved anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

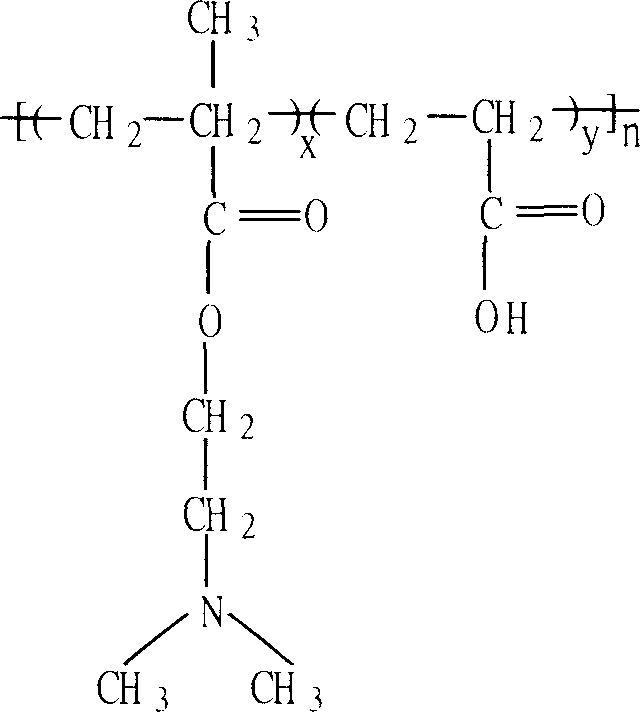

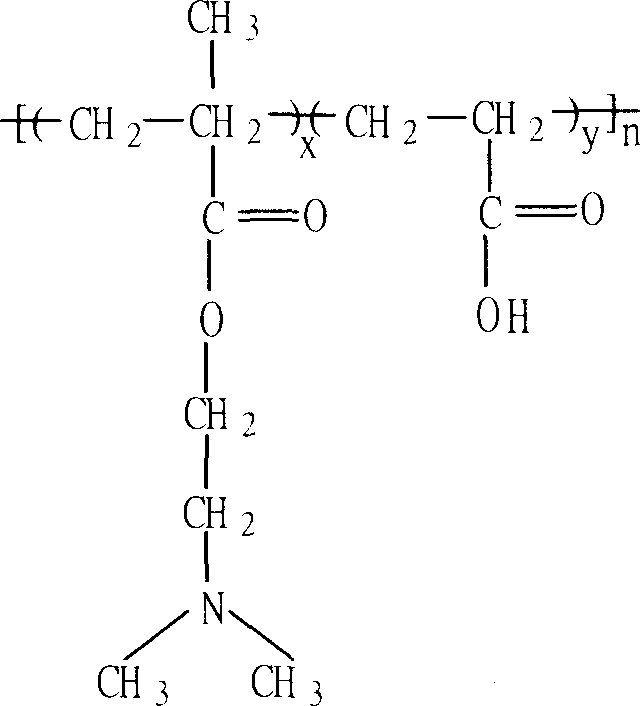

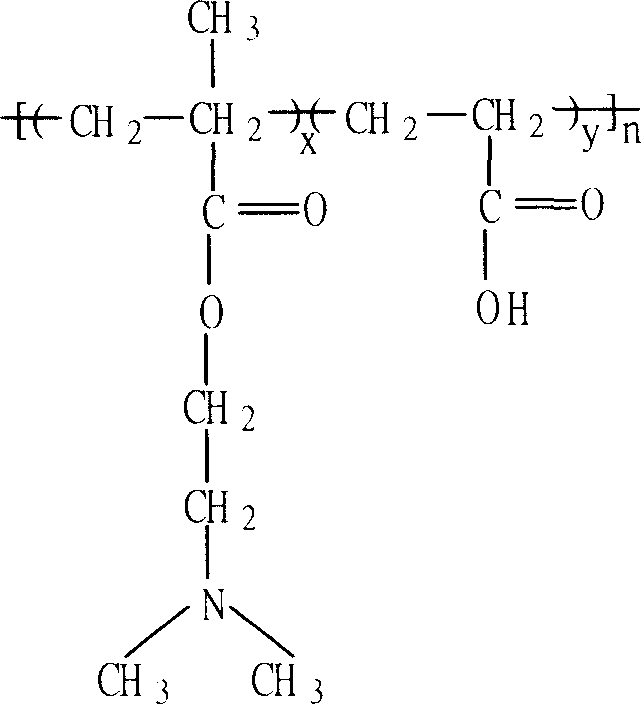

[0021] The method used in the preparation of the copolymer in the preparation method of the present invention is bulk polymerization; the method used in the preparation of the nanofiltration membrane is an interfacial polymerization composite method. The preparation method of the present invention is to coat the coating solution of the copolymer ethanol water on the surface of the base film, and after drying in the shade at room temperature, immerse in the organic phase of the bifunctional alkylation crosslinking agent reacted with the tertiary amino group, and make The linear copolymer chains adsorbed on the surface of the base membrane are cross-linked into a water-insoluble three-dimensional network layer, thereby preparing the nanofiltration membrane with the functional characteristics.

[0022] The composite nanofiltration membrane of the present invention adopts P (DMAEMA-co-AA) cross-linking monomer as the functional layer material, wherein the content of AA is different...

Embodiment 1

[0027] 1. Preparation of P(DMAEMA-co-AA): Distill DMAEMA under reduced pressure to remove the polymerization inhibitor, then mix it with AA, the mixing ratio is x:y=90:10, add 0.005M AIBN, and proceed at 50°C Bulk polymerization, the polymerization time is 5 days;

[0028] 2. Prepare the copolymer coating solution: dissolve the copolymer prepared in the first step with a mixed solution with a ratio of ethanol: water=10:90 to make the copolymer coating solution;

[0029] 3. Prepare the composite nanofiltration membrane in which the copolymer is the functional layer material: evenly coat the copolymer coating liquid prepared in the second step on the surface of the polysulfone base membrane, and after drying in the air, put it into Soak in the pure n-heptane solution containing the cross-linking agent p-dichlorobenzyl for 1 hour, take out the base film after the cross-linking is completed, wash off the unreacted cross-linking agent with lip-reading n-heptane, and make the organi...

Embodiment 2

[0032] 1. Preparation of P(DMAEMA-co-AA): Distill DMAEMA under reduced pressure to remove the polymerization inhibitor, then mix it with AA, the mixing ratio is x:y=8:1, add 0.001M AIBN, and proceed at 70°C Bulk polymerization, the polymerization time is 9 days;

[0033] 2. Prepare the copolymer coating solution: dissolve the copolymer prepared in the first step with a mixed solution with a ratio of ethanol: water=50:50 to make the copolymer coating solution;

[0034] 3. Prepare the composite nanofiltration membrane in which the copolymer is the functional layer material: evenly coat the copolymer coating liquid prepared in the second step on the surface of the polysulfone base membrane, and after drying in the air, put it into Soak in the n-heptane solution containing the cross-linking agent 1,4-dibromobutane for 6 hours, take out the base film after the cross-linking is completed, wash off the unreacted cross-linking agent with n-heptane, and use it in the air After the org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com