Preparation method of nanometer grade active calcium carbonate special for sealing material

A technology of active calcium carbonate and sealing materials, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of thixotropic deterioration, unavoidable agglomeration, and low thixotropic performance of sealing materials, and achieve reduced production costs, narrow particle size distribution, less reunion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

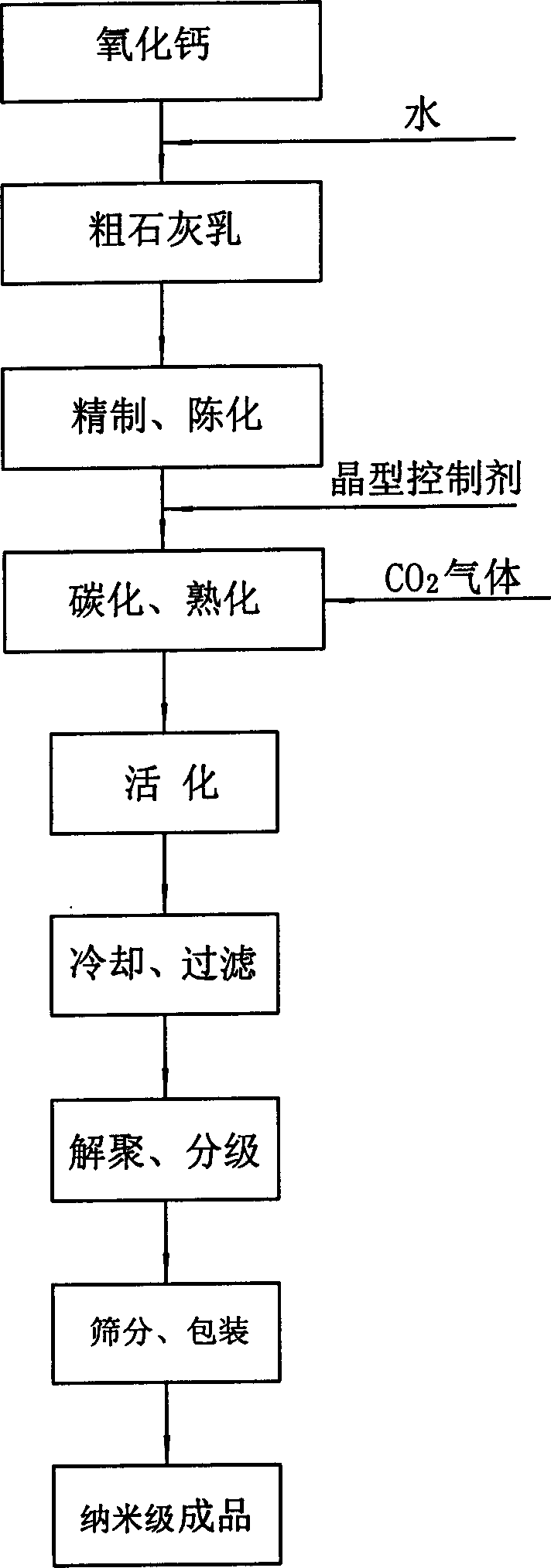

[0019] First of all, raw material preparation is carried out, and medium-burned quicklime is selected. The magnesium oxide index is required to be less than 1.5%, and the activity index is required to be greater than 400mL / 10min. The production process is as follows: figure 1 As shown, the process is as follows:

[0020] In the first step, hot water at 50°C is added to the quicklime, and the water and quicklime are hydrated in the drum digester at a ratio of 6:1 to produce coarse lime milk, which passes through a coarse screen and two-stage 200-mesh screens Refined by filtration, aged in the aging tank for 12 hours and then pumped into the slurry tank to prepare refined milk of lime with a mass concentration of 8%;

[0021] In the second step, CaCO is added to the milk of lime refined in the first step 3 Calcium citrate with a solid content of 0.1%, and stirred evenly, was metered and pumped into the carbonization reactor for stirring, and started circulating cooling to contr...

Embodiment 2

[0030] Under the process condition of above-mentioned embodiment one, changed some process conditions wherein, the parameter of change is:

[0031] Step 1: the temperature of the water, which is 65°C; the mass concentration of the refined milk of lime is 10%;

[0032] Step 2: the addition of calcium citrate is 1%, and the temperature is controlled at about 20°C;

[0033] Step 3: continue to carbonize the pH to 7.0;

[0034] Step 4: the cooked pulp after carbonization was matured for 15 hours, injected with 4% surfactant of calcium carbonate solid content in the slurry, and stirred for 1 hour;

[0035] Step 5: Dry until the moisture content meets customer requirements.

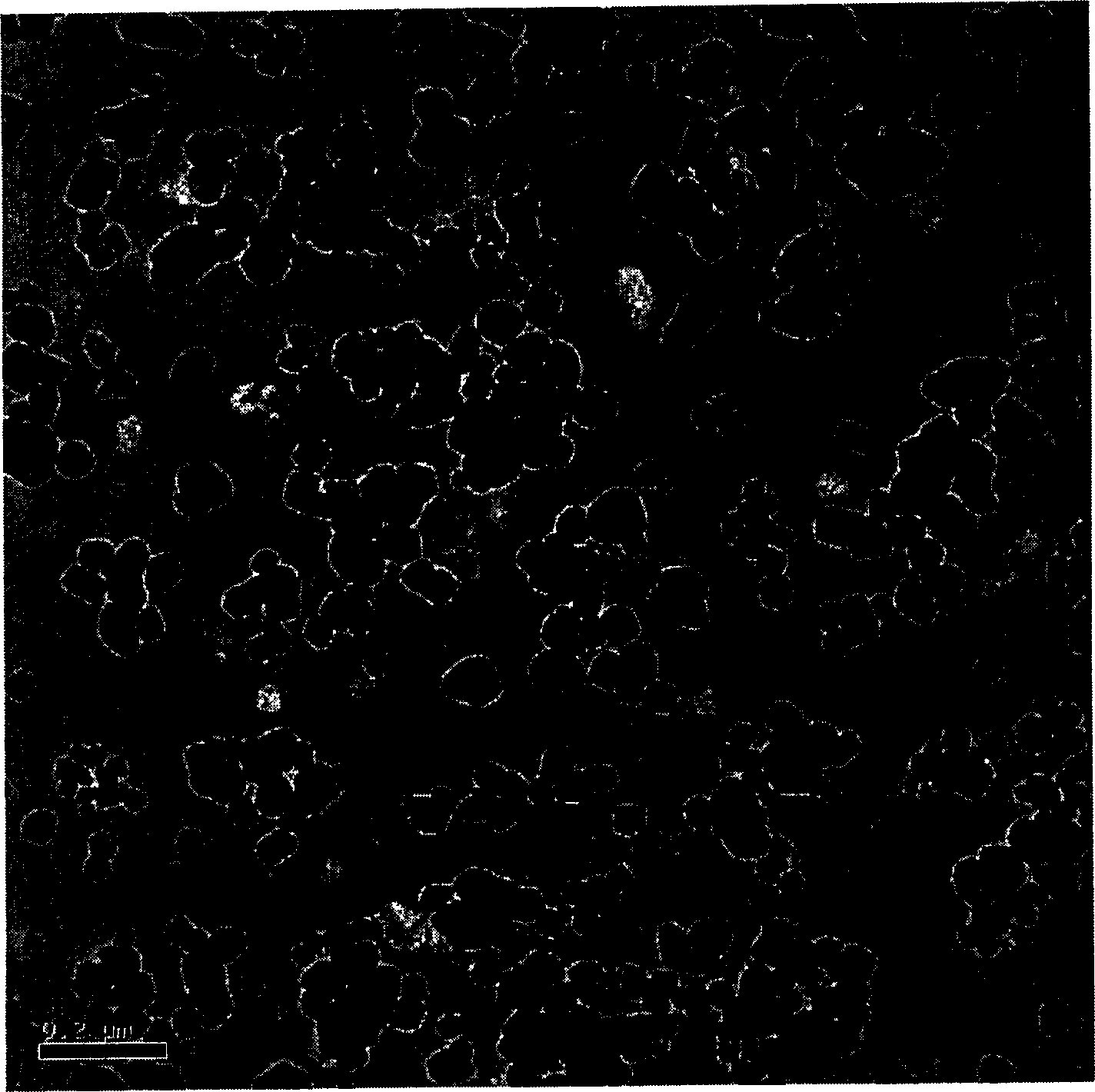

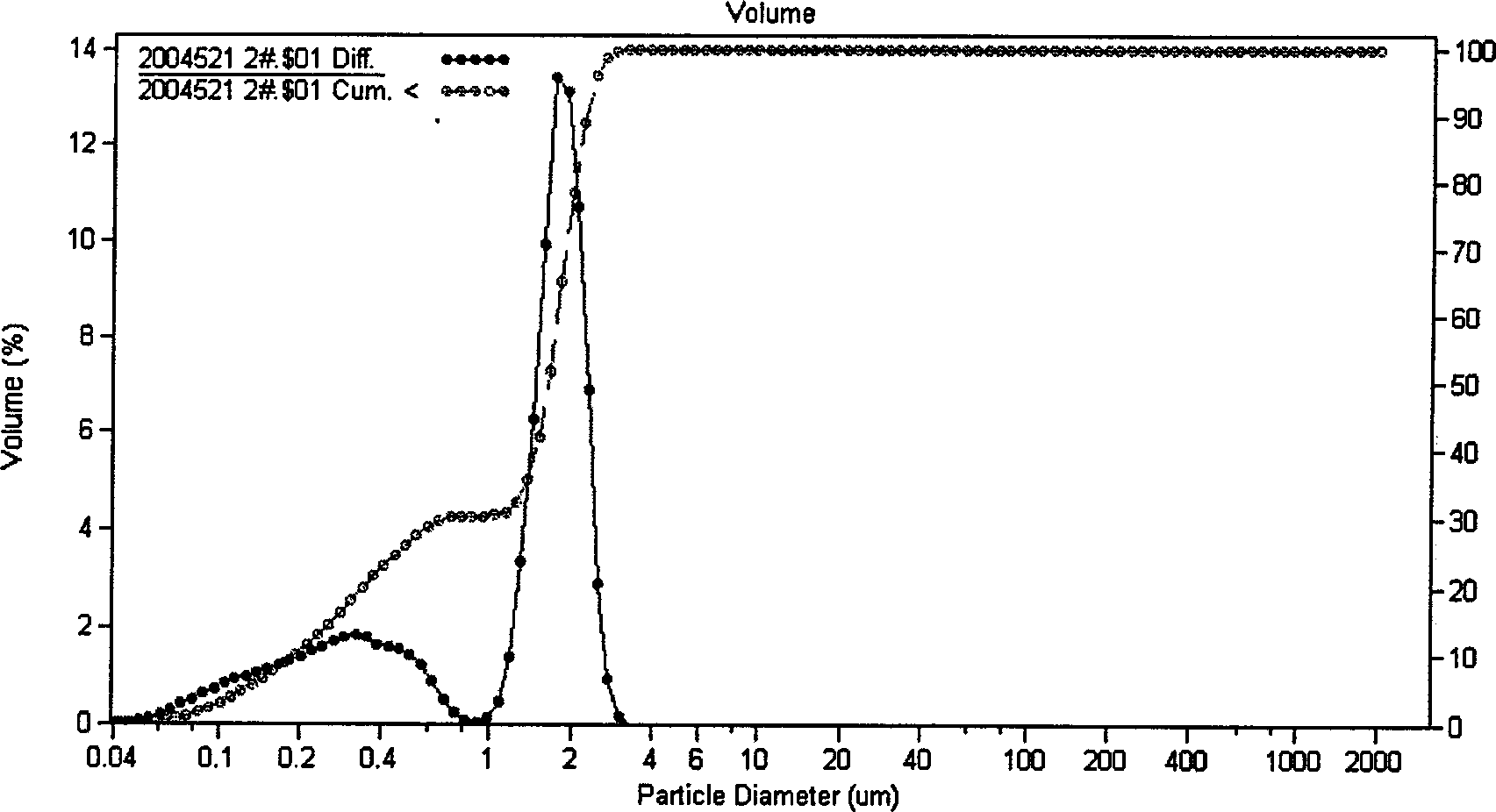

[0036] The calcium carbonate product produced by the above process has complete primary particle crystallization, an average particle size of 40-60nm, less secondary particle agglomeration, and narrow particle size distribution; the crystal form of calcium carbonate is cubic, which is used in sealing material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com