High phosphorus and sulfur ternary composite fertilizer producing process

A ternary compound fertilizer and production method technology, which is applied in the direction of phosphate fertilizer, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problem of neutralizing the amount of phosphoric acid and low viscosity of slurry, affecting the safe operation of equipment, and high viscosity of slurry and other problems, to achieve the effect of increasing total nutrient, small process improvement, and increasing phosphorus content

Inactive Publication Date: 2006-08-02

LUXI CHEM GRP

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the test, it was found that the increase in the amount of phosphoric acid resulted in a low viscosity of the neutralized slurry, which made the subsequent granulation impossible.

[0010] Solution 2: Increase the concentration of phosphoric acid to achieve the effect of high phosphorus, but due to the reason of the device, the concentration of phosphoric acid can only be increased to about 21-22%, and cannot be increased, otherwise, the safe operation of the equipment will be affected

[0011] Later, someone asked whether it is possible to carry out technological transformation to increase the concentration of phosphoric acid. After expert demonstration and calculation, if the phosphoric acid production process is transformed, equipment must be added, and the cost will increase significantly. Exhaust gas (fluoride) pollution cannot meet the operating requirements of the GB / T24001-2000 environmental system, and environmental protection facilities must be added at the same time, but this investment is relatively large, and due to the concentration of phosphoric acid, the viscosity of phosphoric acid increases. The viscosity of the slurry is high, the neutralization degree control is not easy to improve, and the corrosion of the equipment is quite serious. After putting into operation, the ideal effect cannot be achieved, and finally this plan was also abandoned.

[0012] As mentioned above, because the existing production equipment cannot produce compound fertilizer with high phosphorus content, the development of product sales market is limited. Therefore, how to produce compound fertilizer with high phosphorus content on the basis of existing production equipment to adapt to the market What is needed is a difficult problem on the development road of compound fertilizer production enterprises

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0031] Example 1: Potassium chloride: 204, sulfuric acid: 312, phosphoric acid: 669, liquid ammonia: 121, monoammonium phosphate: 152

example 2

[0032] Example 2: Potassium chloride: 185, sulfuric acid: 283, phosphoric acid: 605, liquid ammonia: 111, monoammonium phosphate: 273

example 3

[0033] Example 3: potassium chloride: 172, sulfuric acid: 264, phosphoric acid: 565, liquid ammonia: 104, monoammonium phosphate: 363

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

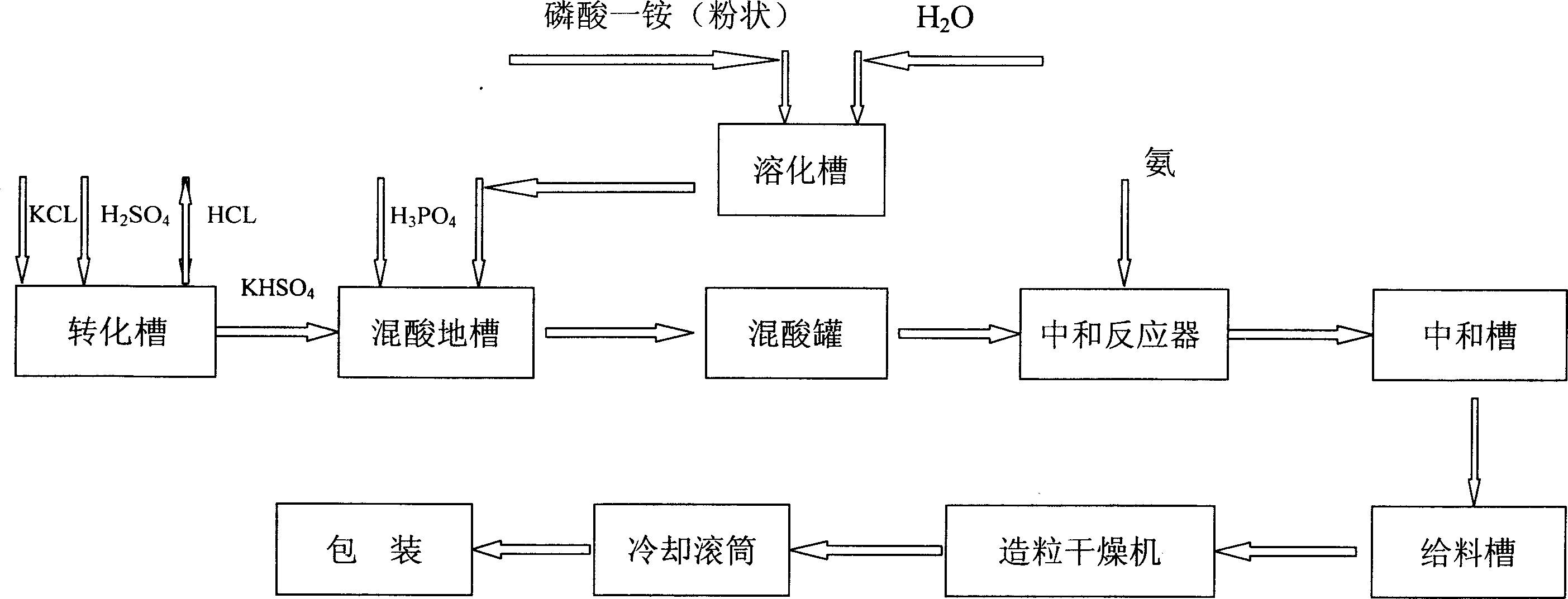

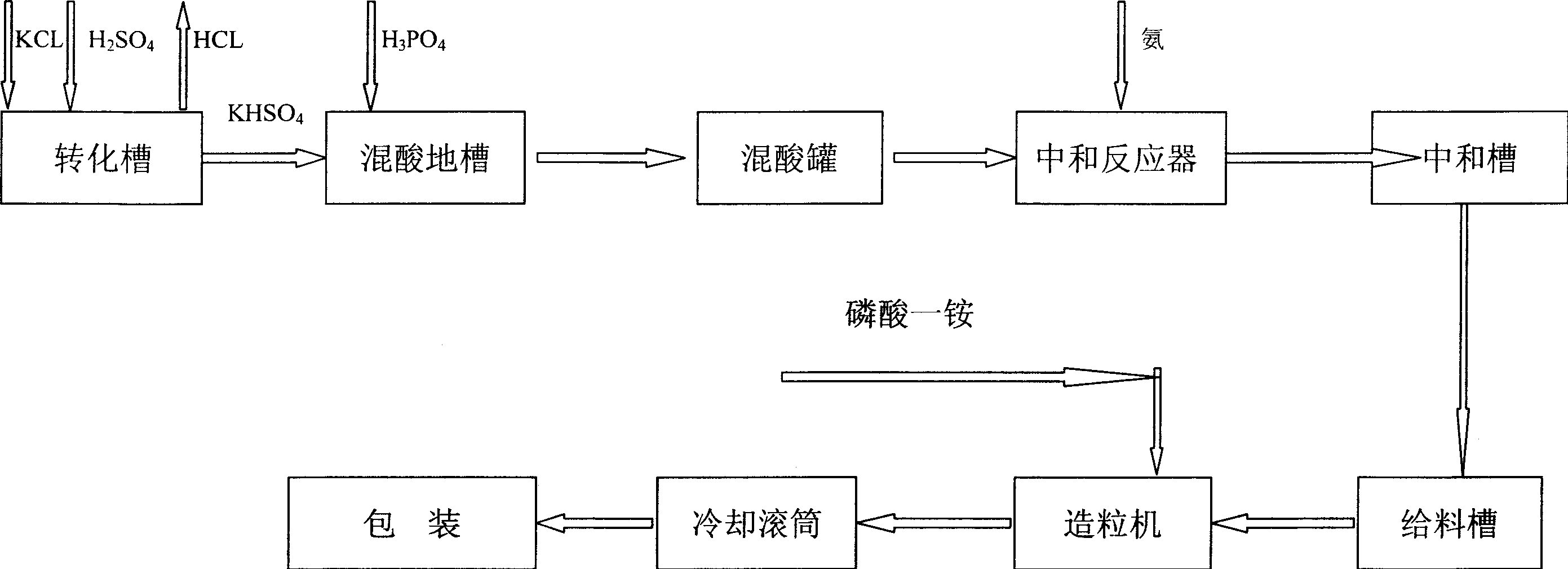

The high phosphorus and sulfur ternary composite fertilizer as one kind one chemical fertilizer is produced through the steps of: conversion reaction of KCl and H2SO4 inside a converting tank, mixing with phosphoric acid inside the acid mixing ground tank, the neutralization of acid mixture and ammonia in a tubular reactor, conveying the reacted product from the neutralizing tank to the material feeding tank, and pelletizing and drying in a pelletizing and drying machine. The production process features the addition of certain amount of monoammonium phosphate to the acid mixing ground tank or pelletizing and drying machine, and the neutralizing degree controlled in 1.14-1.19. The high phosphorus and sulfur ternary composite fertilizer has high nutrient content and is especially suitable for use in area with soil lacking one phosphate.

Description

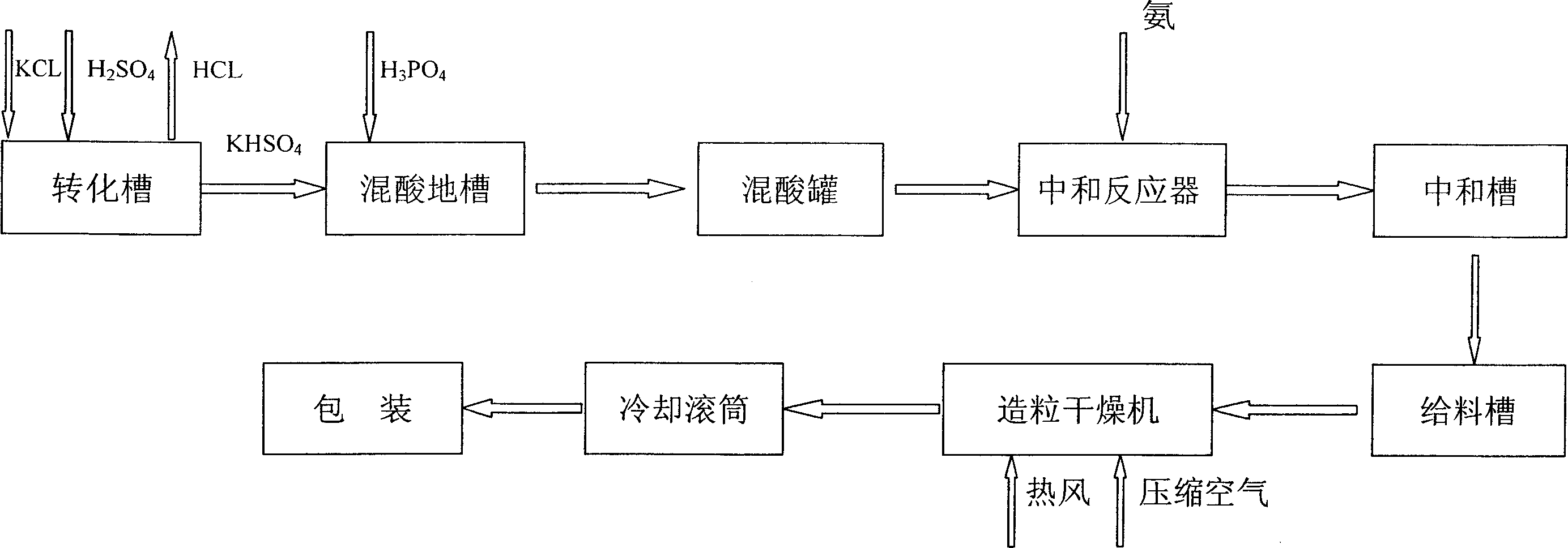

technical field [0001] The invention relates to a production method of compound fertilizer, in particular to a production method of high phosphorus and sulfur-based ternary compound fertilizer. Background technique [0002] Chemical fertilizers refer to fertilizers made from minerals, air, and water through chemical or mechanical processing. They are developed on the basis of natural fertilizers. According to the results of the investigation by the Food and Agriculture Organization of the United Nations, the average yield increase effect of chemical fertilizers can reach 40-60%. Nitrogen, phosphorus, and potassium fertilizers are the three basic fertilizers in chemical fertilizers. [0003] Such as figure 1 . The existing sulfur-based compound fertilizer production process is: [0004] KCI enters the conversion tank after being measured by a disc feeder and a screw weighing scale; the sulfuric acid stored in the sulfuric acid tank is sent to the reaction tank in proporti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C05G1/00C05G5/00C05B7/00C05D1/02

Inventor 王延吉王存申孙海兵张长卿董玉中王德民

Owner LUXI CHEM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com