Method for preparing hano-level titanium dioxide by controlling crystal form

A titanium dioxide, nano-scale technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of limitation and high cost of raw materials, and achieve the effect of process operation, uniform particle size and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the titanyl sulfate deionized water, slowly add 5mol / L sodium hydroxide solution, the whole process controls the reaction temperature to not exceed 40℃, and terminates when the pH is 5; filter and wash twice with deionized water to 0.1mol / L BaCl 2 Solution can not detect SO 4 2- Add 6mol / L hydrochloric acid under stirring conditions to dissolve the resulting filter cake, and control the temperature at 20°C. When it is completely dissolved, stop adding acid; add 2.5% potassium citrate, and hydrolyze at 95°C for 1 hour, The product is filtered, washed with deionized water twice, dried at 100°C, and then moved into a muffle furnace and calcined at 700°C for 1.5 hours to obtain mixed crystal titanium dioxide powder with 75% rutile and 25% anatase.

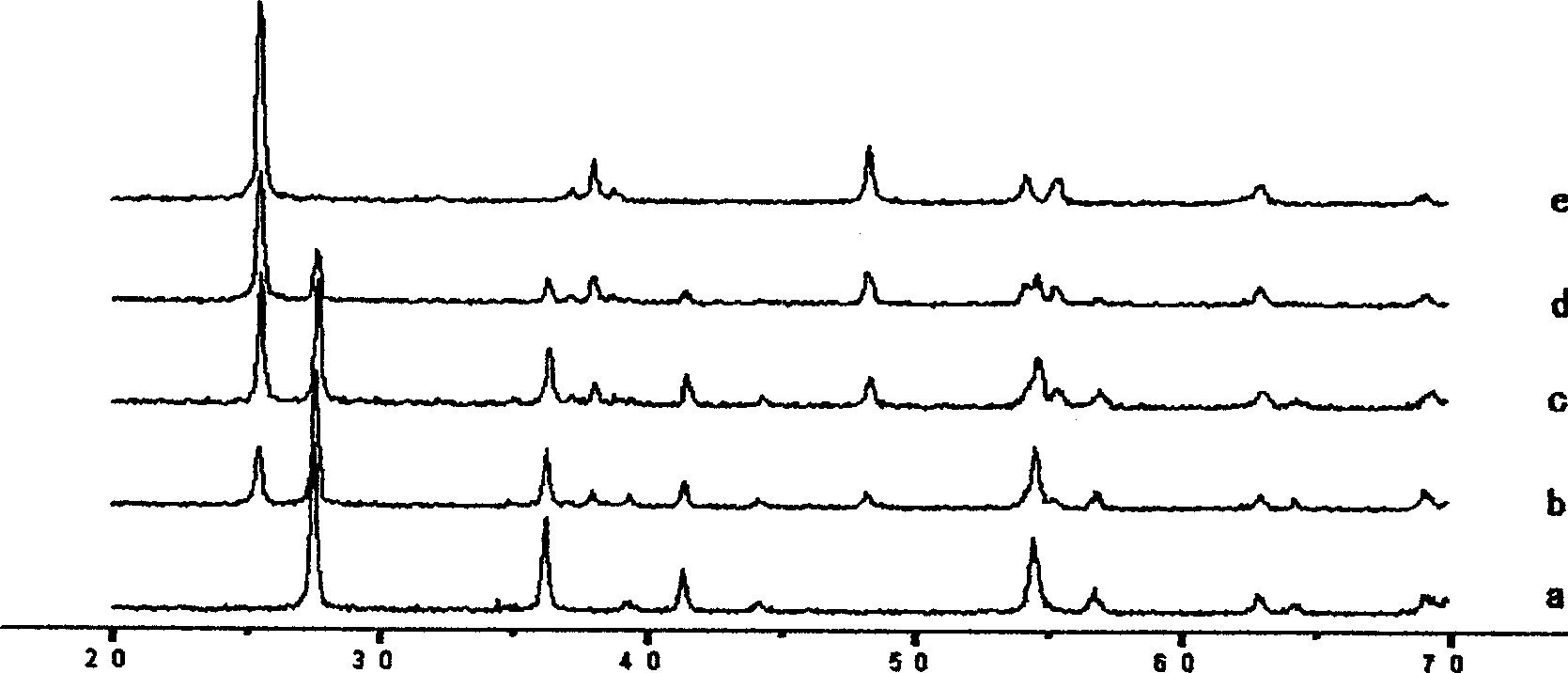

[0026] X-ray diffraction pattern such as figure 1 (b) Shown.

Embodiment 2

[0028] In the titanyl sulfate deionized water, slowly add 5mol / L sodium carbonate solution, the whole process controls the reaction temperature not to exceed 40℃, and terminates when the pH is 7; filter and wash to 0.1mol / L BaCl 2 Solution can not detect SO 4 2- Add 3mol / L hydrochloric acid under stirring conditions to dissolve the resulting filter cake, and control the temperature at 10℃, when it is completely dissolved, stop adding acid; add 5% sodium citrate, and hydrolyze at 105℃ for 0.5h The product is filtered, washed, dried at 120°C, moved into a muffle furnace and calcined at 650°C for 1.5 hours to obtain mixed crystal titanium dioxide powder with 50% rutile and 50% anatase.

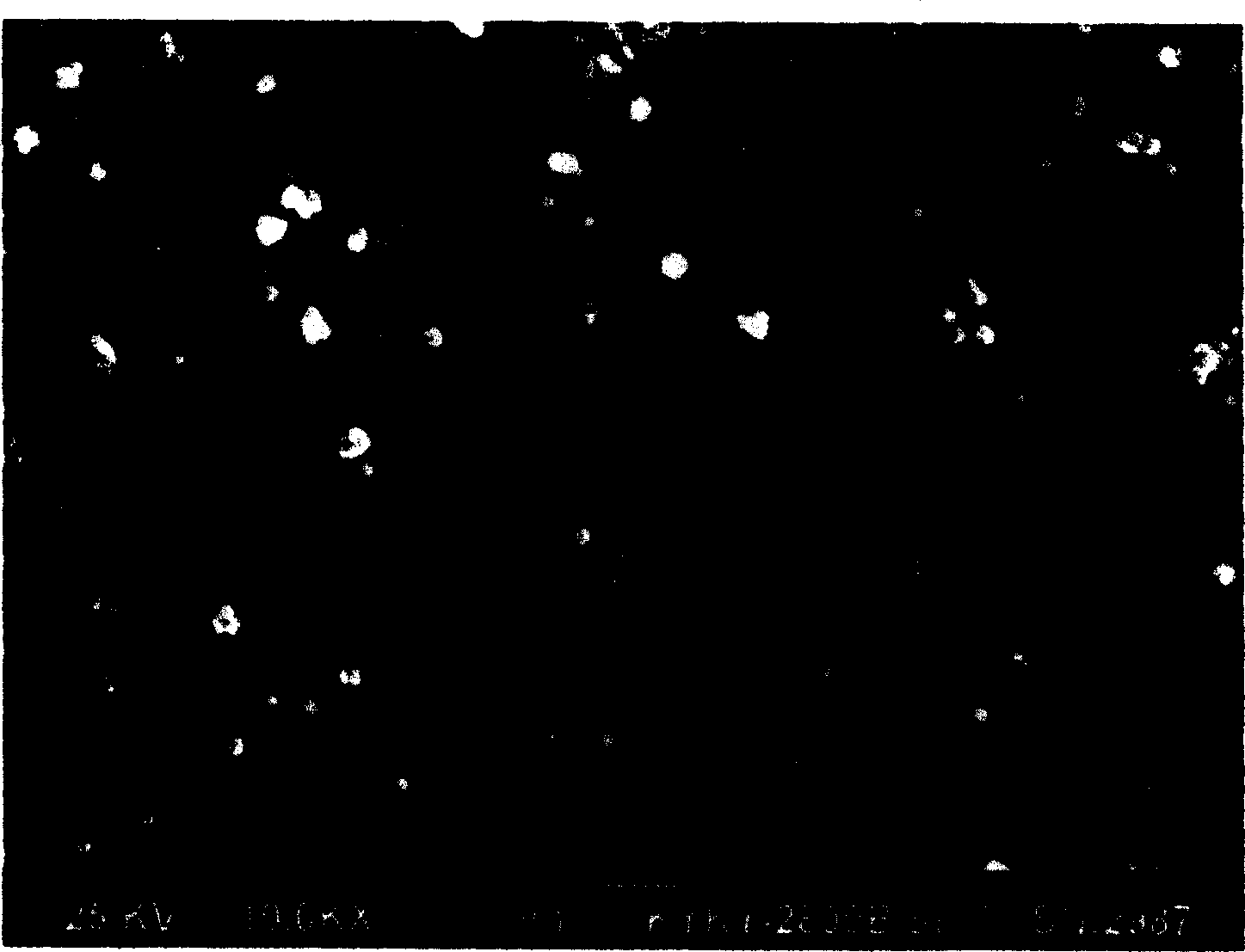

[0029] X-ray diffraction pattern such as figure 1 As shown in (c), the SEM image of the obtained sample is as figure 2 Shown.

Embodiment 3

[0031] In the titanyl sulfate deionized water, slowly add 2mol / L potassium carbonate solution, the whole process is controlled to control the reaction temperature not to exceed 40℃, and the pH is 9 to terminate; filter and wash until 0.1mol / L BaCl 2 Solution can not detect SO 4 2- Add 2mol / L hydrochloric acid under stirring conditions to dissolve the resulting filter cake, and control the temperature at 20℃, when it is completely dissolved, stop adding acid; add 10% sodium salicylate, and hydrolyze at 85℃ for 1.5h Afterwards, the product is filtered, washed, dried at 40°C, moved into a muffle furnace and calcined at 630°C for 1.5 hours to obtain mixed crystal titanium dioxide powder with rutile type accounting for 25% and anatase accounting for 75%.

[0032] X-ray diffraction pattern such as figure 1 (d) Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com