Enzyme test peper for detecting hydrogen peroxide concentration

A technology of horseradish peroxidase and test paper, which is applied in the field of enzymatic analysis in the field of biotechnology, can solve the problems of cumbersome operation and unfavorable wide use, and achieve the effect of being easy to carry and suitable for mobile operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

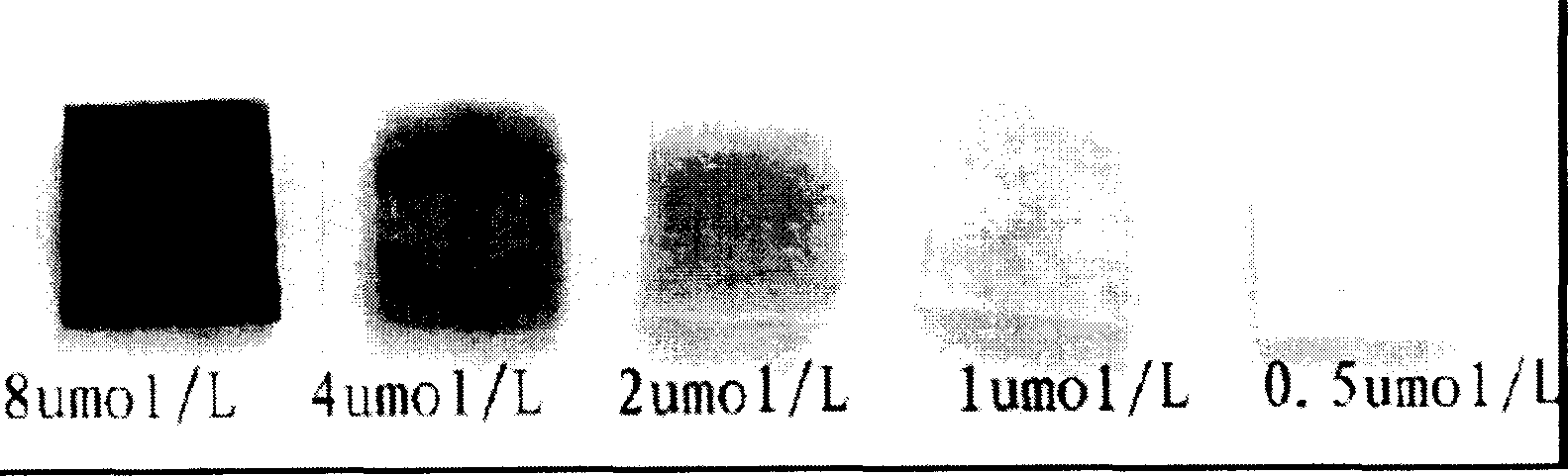

[0015] Preparation of Enzyme Test Paper for Determination of Hydrogen Peroxide Concentration

[0016] Take thick qualitative filter paper and cut it into 1cm×3cm size, soak it in 1% carboxymethyl cellulose aqueous solution for about 60 minutes, after fully imbibition, dry it, and then soak the filter paper strip in 20ml containing color reagent And in the mixed solution of horseradish peroxidase, wherein the composition of mixed solution is: phenol 0.025M, 4-aminoantipyridine 0.0075M, horseradish catalase 0.025g / L (W / V), ampicillin Penicillin 100mg / L (W / V). After shaking at 4°C for 60 minutes, take out the filter paper, dry it at low temperature, and finally store it in a sealed plastic bag at low temperature and avoid light. That is, the enzyme test paper that can be used for the determination of hydrogen peroxide concentration is prepared.

Embodiment 2

[0018] Preparation of Enzyme Test Paper for Determination of Hydrogen Peroxide Concentration

[0019] Cut the carboxymethyl cellulose membrane into a size of 1cm×3cm (because the carrier itself is carboxymethyl cellulose, which already has negatively charged anionic groups, so it is not necessary to soak it in carboxymethyl cellulose aqueous solution), then soak it in 20ml In the mixed solution of chromogen and horseradish peroxidase, wherein the mixed solution consists of: phenol 0.02M, 4-aminoantipyridine 0.005M, horseradish catalase 0.01g / L (W / V ), tetracycline 10mg / L (W / V). After shaking at 4°C for 60 minutes, take out the filter paper, dry it at low temperature, and finally store it in a sealed plastic bag at low temperature and avoid light. That is, the enzyme test paper that can be used for the determination of hydrogen peroxide concentration is prepared.

Embodiment 3

[0021] Preparation of Enzyme Test Paper for Determination of Hydrogen Peroxide Concentration

[0022] Cut the nitrocellulose membrane into a size of 1cm×3cm (because the carrier itself is nitrocellulose, which already has a negatively charged anion group, so it is not necessary to soak it in an aqueous carboxymethyl cellulose solution), and then soak it in 20ml of chromogen and In the mixed solution of horseradish peroxidase, wherein the mixed solution is composed of: phenol 0.10M, 4-aminoantipyridine 0.05M, horseradish catalase 0.025g / L (W / V), kana Mycin 50mg / L (W / V). After shaking at 4°C for 60 minutes, take out the filter paper, dry it at low temperature, and finally store it in a sealed plastic bag at low temperature and avoid light. That is, the enzyme test paper that can be used for the determination of hydrogen peroxide concentration is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com