Materials dedicated for antibacterial and permeable polyolefin film and preparation method thereof

A technology of polyolefin and breathable membrane, which is applied in the field of special materials for polyolefin antibacterial and breathable membranes. It can solve the problems of non-bacterial, complex process requirements, and difficult control of phase separation, and achieve the effect of ensuring uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

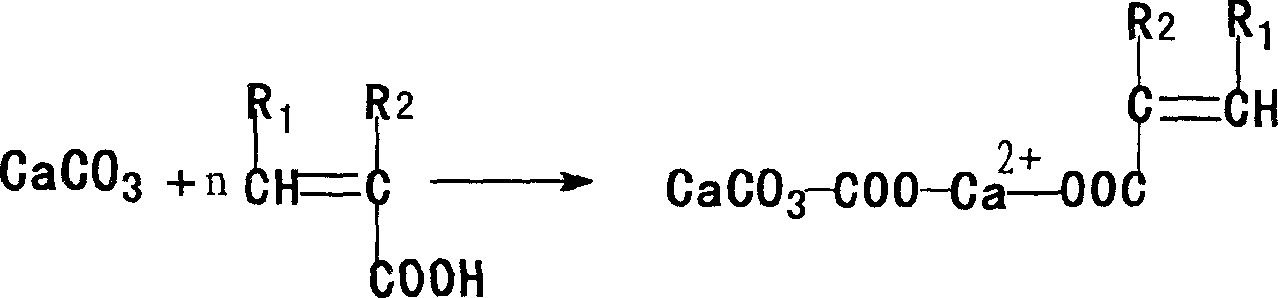

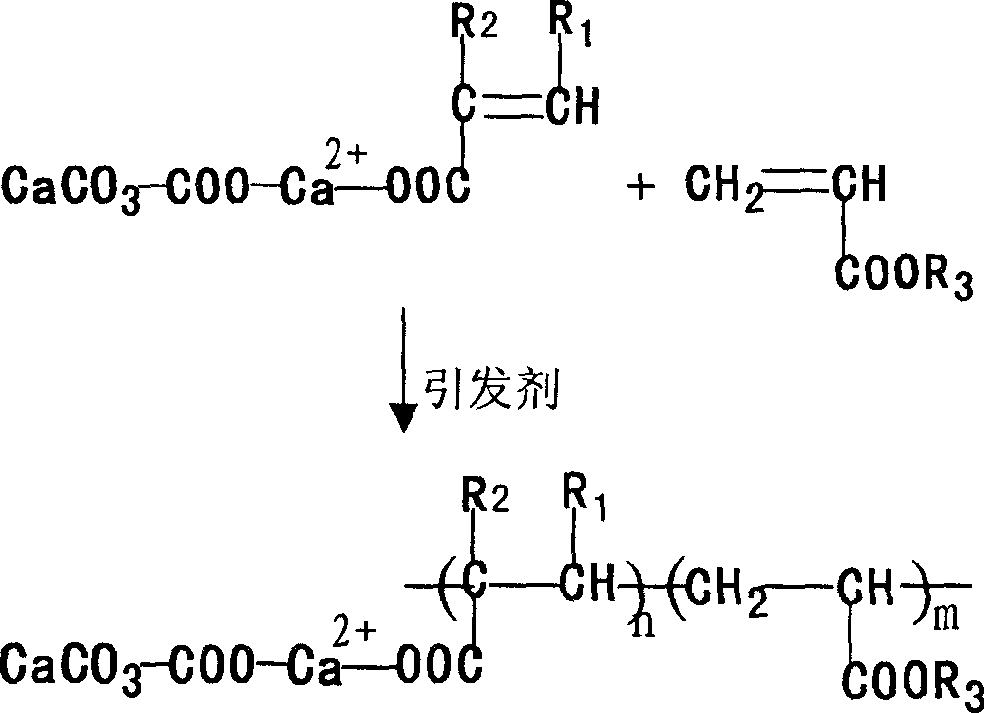

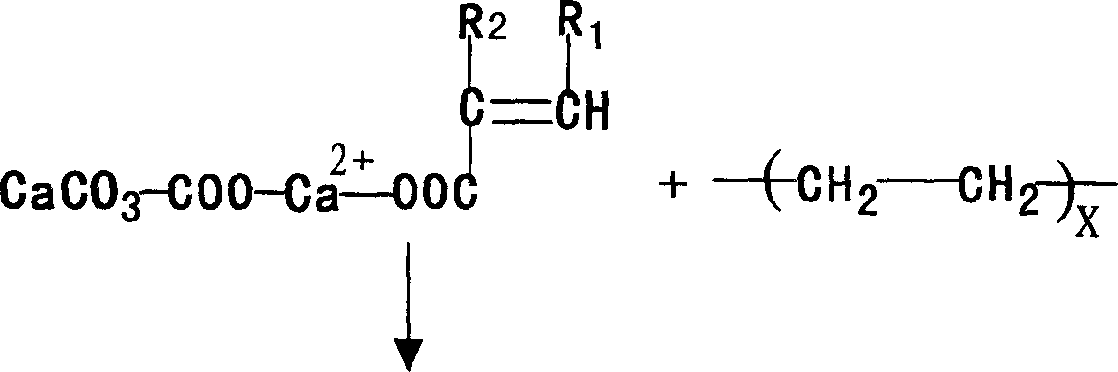

Method used

Image

Examples

Embodiment 1

[0067] In a 200-liter kneader, add 20 kg of nano-calcium carbonate (with a particle size of 30 to 65 nanometers) and 60 kg of heavy calcium carbonate (with a particle size of 6 to 10um) according to the formula in Example 1 of Table 1. Under low-speed stirring, add 0.8 kg of methacrylic acid, 0.8 kg of stearyl methacrylate, 0.008 kg of di-tert-butyl peroxide, and 1 kg of sodium hexadecyloxy polyoxyethylene ether sulfonate ( The degree of polymerization of polyoxyethylene ether is 20), 3 kg of maleic anhydride grafted linear low-density polyethylene (grafting rate 1.2 mmol / 100 g) and 14.4 kg of linear low-density polyethylene (melt flow rate is 17g / 10min), after the addition, stir at high speed for 1 minute to obtain a mixture.

[0068] Put the mixture into the feeding hopper of the twin-screw extruder, extrude and cut pellets in a twin-screw extruder with a 48:1 length-to-diameter ratio and a screw diameter of 75mm with a screw plus 5-stage mixing elements. The main engine speed o...

Embodiment 2

[0072] According to the same processing conditions as in Example 1, the mixed calcium carbonate pre-dispersed masterbatch HCM-2 was prepared according to the formula of Table 1 and Example 2, and the special material for polyolefin antibacterial breathable film GPM-2 was prepared according to the formula of Example 2 of Table 2. . The difference from Example 1 is that GPM-2 is suitable for blowing into a film to make a breathable film.

Embodiment 3

[0074] The steps are the same as in Example 1, and the mixed calcium carbonate pre-dispersed masterbatch HCM-3 is prepared according to the formula of Example 3 in Table 1. The processing conditions are different from that in Example 1: The main engine speed of the twin-screw extruder is 280 rpm, the feeding speed is 40 rpm, and the temperature of each section of the extruder (including the head of the 6 sections) is sequentially 180°C, 200°C, 200°C, 195°C, 195°C, 190°C. According to the formula of Example 3 in Table 2, the special material GPM-3 for polyolefin antibacterial breathable film was prepared.

[0075] Example 1

[0076] Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com