Li4Ti5O12 materials with spinel structure and preparation process and use thereof

A spinel structure, 10ppm-5wt.% technology, applied in the field of electrochemistry, can solve the problems of electrode capacity decline, voltage hysteresis, inability to significantly improve Li, etc., and achieve improved electrical conductivity, stable structure, and excellent fast charge-discharge performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

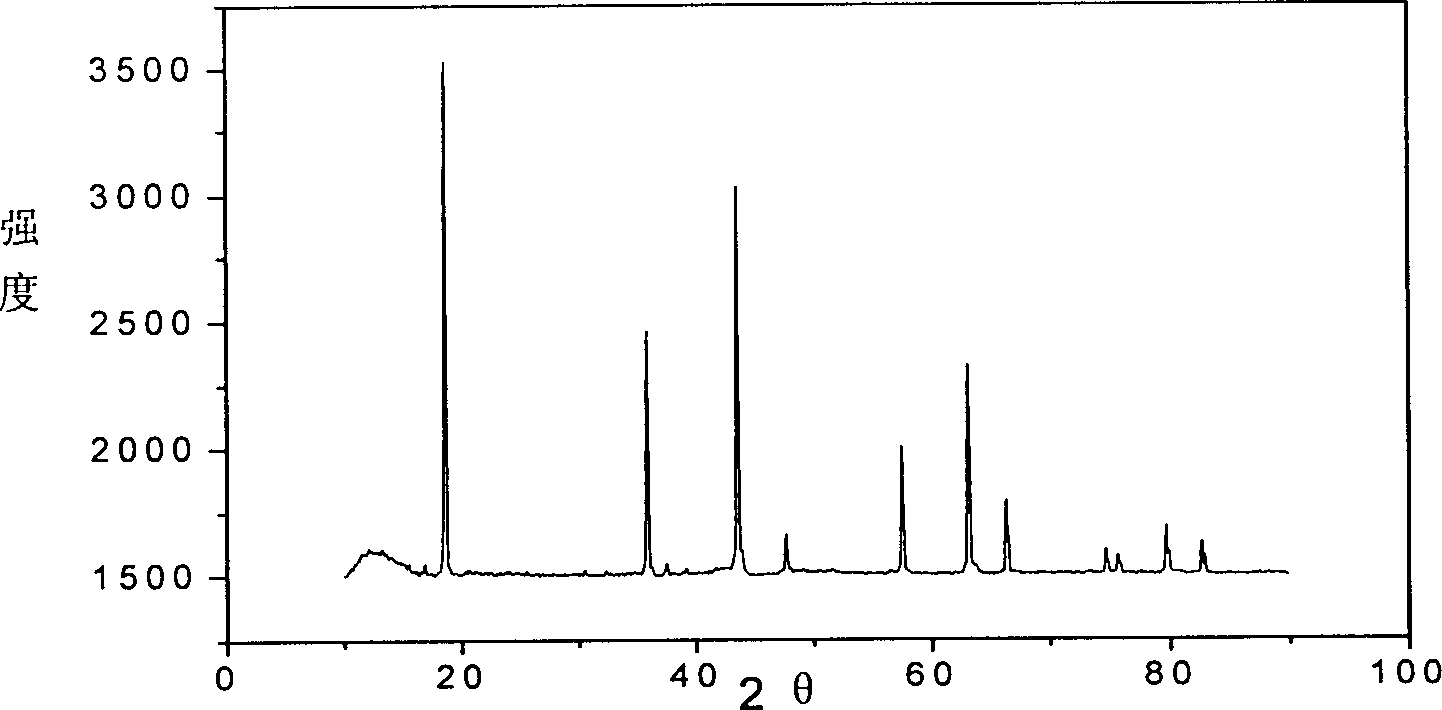

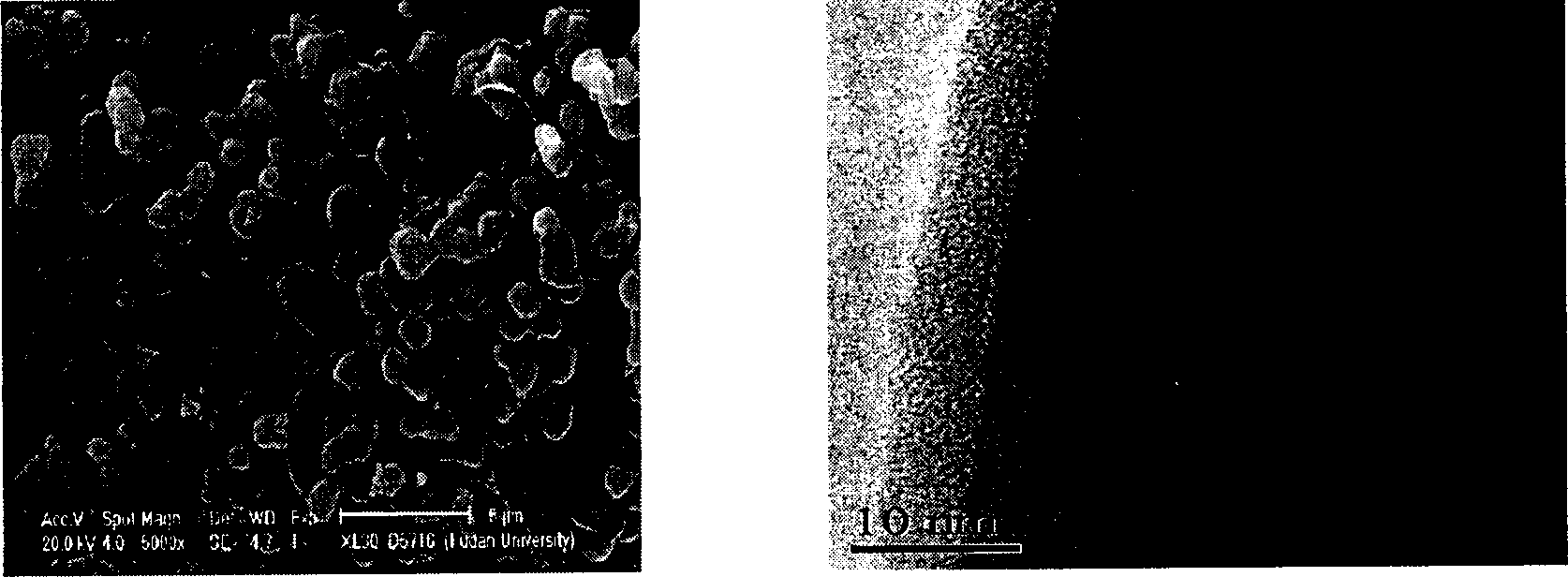

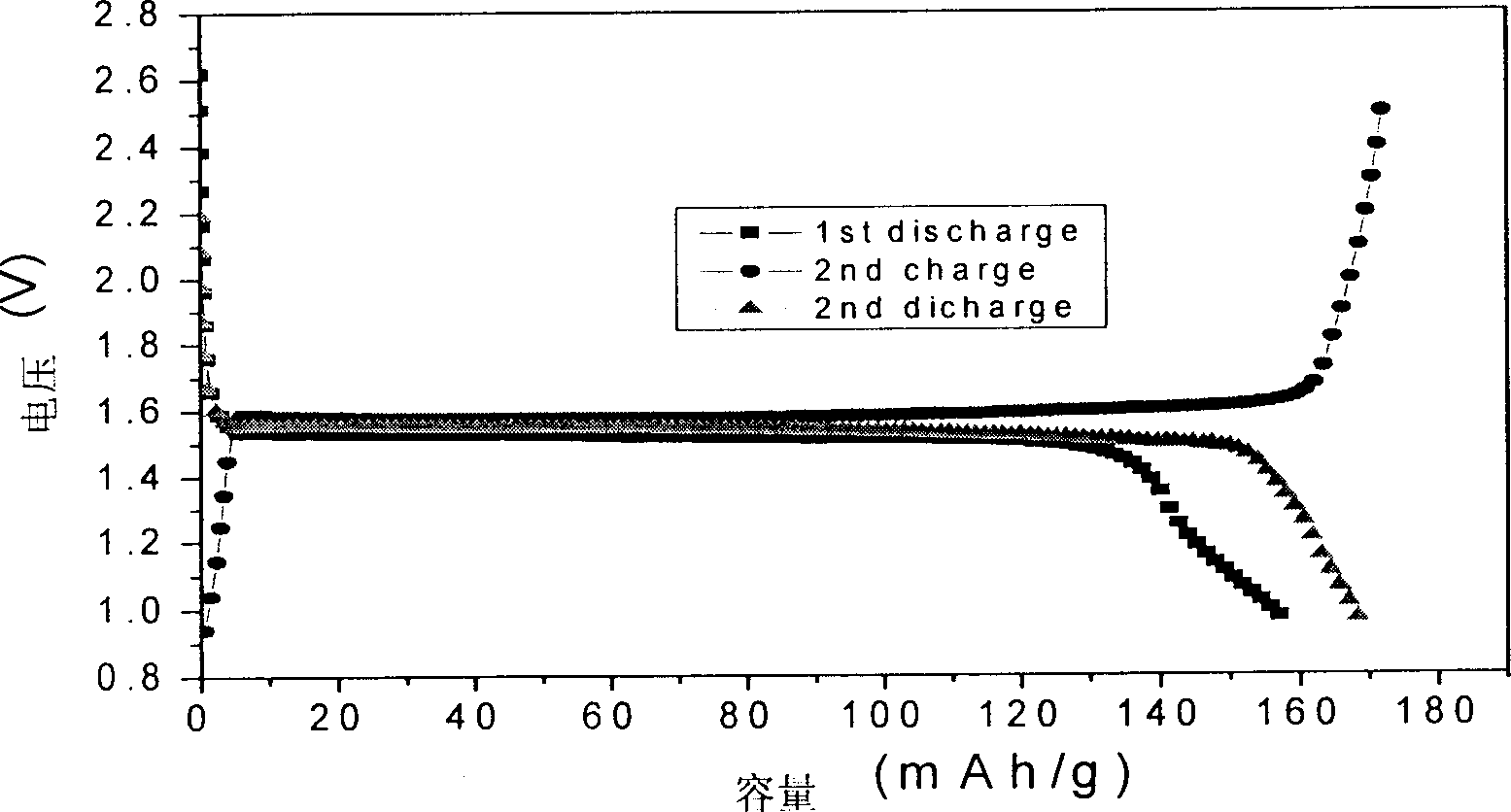

[0027] Mix the raw materials lithium carbonate and titanium dioxide in a molar ratio Li:Ti=0.85:1, and mix with 10% sucrose, add it to the mixing tank, add an appropriate amount of agate balls, seal the mixing tank, and put it on the ball mill at 300 rpm ball milling at a high speed for 12 hours to obtain a homogeneously mixed raw material. Then it was heated in a muffle furnace at 750°C for 12 hours to decompose the raw materials. The temperature was raised to 850° C. for 24 hours, and then the furnace was allowed to cool down to room temperature. Get the Li spinel structure 4 Ti 5 o 12 . figure 1 It is the XRD pattern of the obtained product, compared with the following comparative example 1, the addition of additives does not change Li 4 Ti 5 o 12 The crystal structure, maintained with Li 4 Ti 5 o 12 All the diffraction peaks can be identified according to the standard XRD spectrum of the same crystal structure, and no impurity peaks of additives and their pyrolys...

Embodiment 2

[0031] Mix the raw materials lithium carbonate and titanium dioxide in a molar ratio of Li:Ti=0.85:1, and mix with 10% sucrose, add to the mixing tank, add an appropriate amount of agate balls, seal the mixing tank, and put it on the ball mill at 400 rpm ball milling at a high speed for 24 hours to obtain evenly mixed mixed raw materials. Then, under the protection of inert gas, it was heated in a tube furnace at 700°C for 18 hours to decompose the raw materials. The decomposed product is a black powder, which is uniformly ground and placed in a tube furnace again, and calcined at 900°C for 24 hours under the protection of an inert gas, and then the furnace is allowed to cool down to room temperature. get Li 4 Ti 5 o 12 . The carbon content in the material is 0.5wt.%, the reversible capacity is 120mAh / g, and it does not decay after 30 cycles.

Embodiment 3

[0033] The raw materials lithium carbonate and titanium dioxide are mixed according to the molar ratio Li:Ti=0.76:1, and mixed with 10% acetylene black, put into the mixing tank, add an appropriate amount of agate balls, seal the mixing tank, and put it on the ball mill at 300 rpm Minute speed ball milling for 24 hours to obtain evenly mixed mixed raw materials. Then it was heated in a muffle furnace at 750°C for 12 hours to decompose the raw materials. The temperature was raised to 900° C. for 24 hours, and then the furnace was allowed to cool down to room temperature. Li with a spinel structure 4 Ti 5 o 12 . The material has a capacity of 145mAh / g and does not decay after 30 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com