Process for preparing high purity soy phoshatidylcholine without lysophosphatide

A technology of phosphatidylcholine and lysophospholipid, which is applied in the field of phospholipids, can solve the problems such as failure to remove lysophospholipids and inability to realize industrialized production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

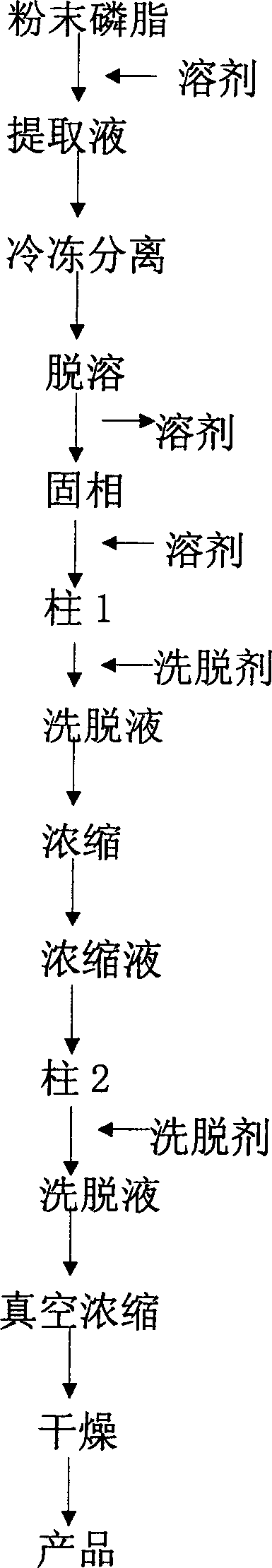

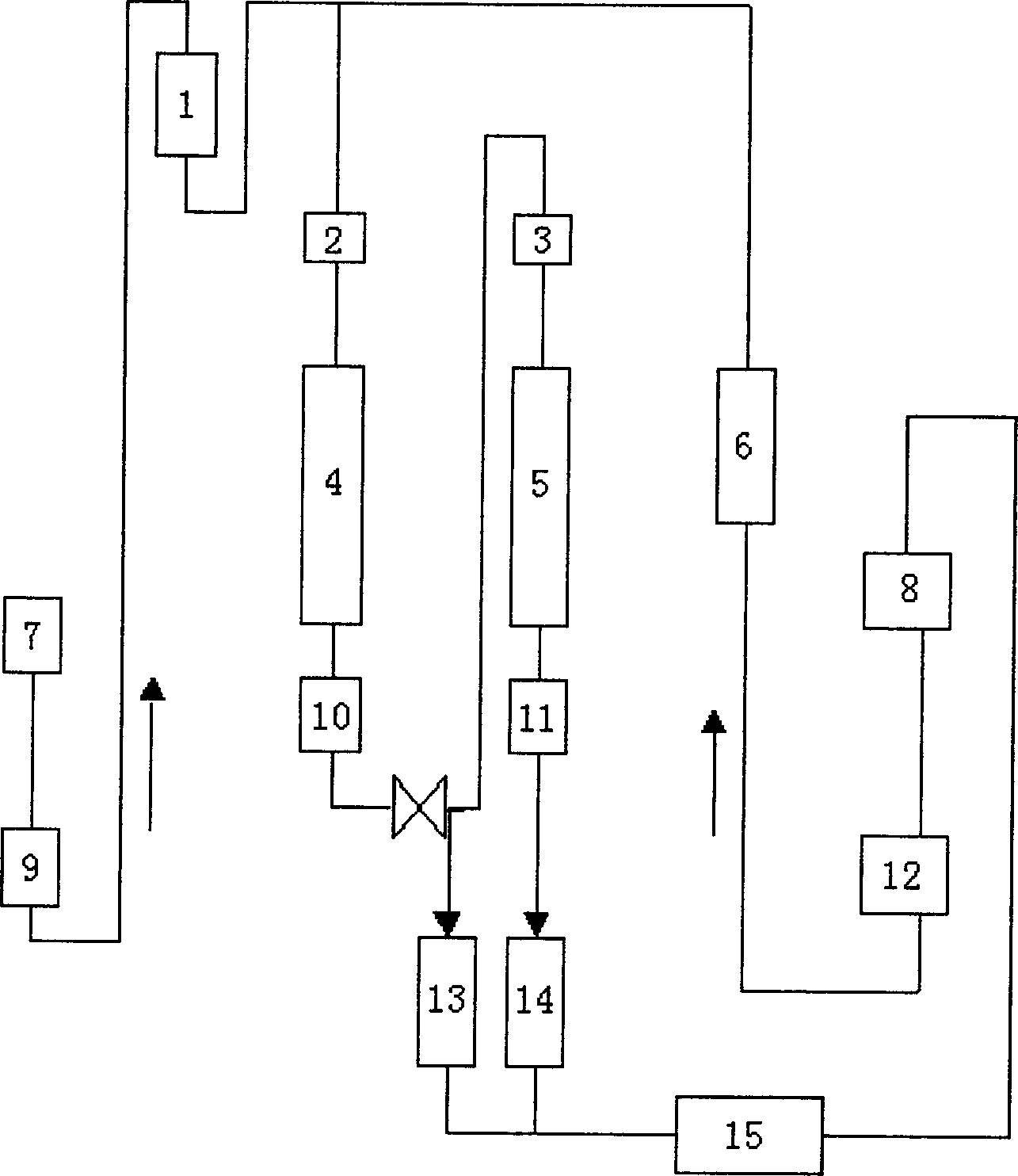

Method used

Image

Examples

Embodiment 1

[0019] Add 100 grams of powdered phospholipids to 300 milliliters of 95% ethanol, stir and leach for half an hour at room temperature, take the supernatant and let stand at -5°C for 24 hours, filter, and remove ethanol. Prepare an ethanol solution with a solid mass concentration of 2%, pass through an aluminum oxide column, and elute with 95% ethanol at 45°C. % ethanol was eluted, and the eluent was further vacuum-dried to obtain 7.5 g of the product after vacuum precipitation.

[0020] Acid value (mg / g)

Embodiment 2

[0022] Add 100 grams of powdered phospholipids to 700 milliliters of 80% methanol, stir and leach for half an hour at room temperature, take the supernatant and concentrate to half of the original volume, stand at -6°C for 20 hours, filter, and remove methanol. Prepare a methanol solution with a solid mass concentration of 2%, pass through a manganese dioxide column, and elute with 80% methanol at 20°C. After concentrating the eluent 10 times, pass through a diatomite column, 80% ethanol was eluted, and the eluent was further vacuum-dried after vacuum precipitation to obtain 9.2 g of the product.

Embodiment 3

[0024] Add 100 grams of powdered phospholipids to 1100 milliliters of 90% propanol, stir and leach for half an hour at room temperature, take the supernatant and concentrate to one-third of the original volume, stand at -8°C for 15 hours, filter, and remove the solvent. Prepare a propanol solution with a solid mass concentration of 2%, pass through an aluminum oxide column, and elute with 90% propanol at 50° C., concentrate the eluate by 10 times, pass through an attapulgite column, It was eluted with 90% propanol at °C, and the eluent was vacuum-precipitated and further vacuum-dried to obtain 4.7 g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com