Separating method for converting methanol to prepare low carbon olefin gas

A low-carbon olefin and methanol conversion technology, which is applied in the field of light hydrocarbon refining, can solve the problems of accumulation of dangerous substances, explosion of cold box parts, increase of unsafe factors in the system, etc., and achieve the goal of shortening the process, reducing power consumption and improving operation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

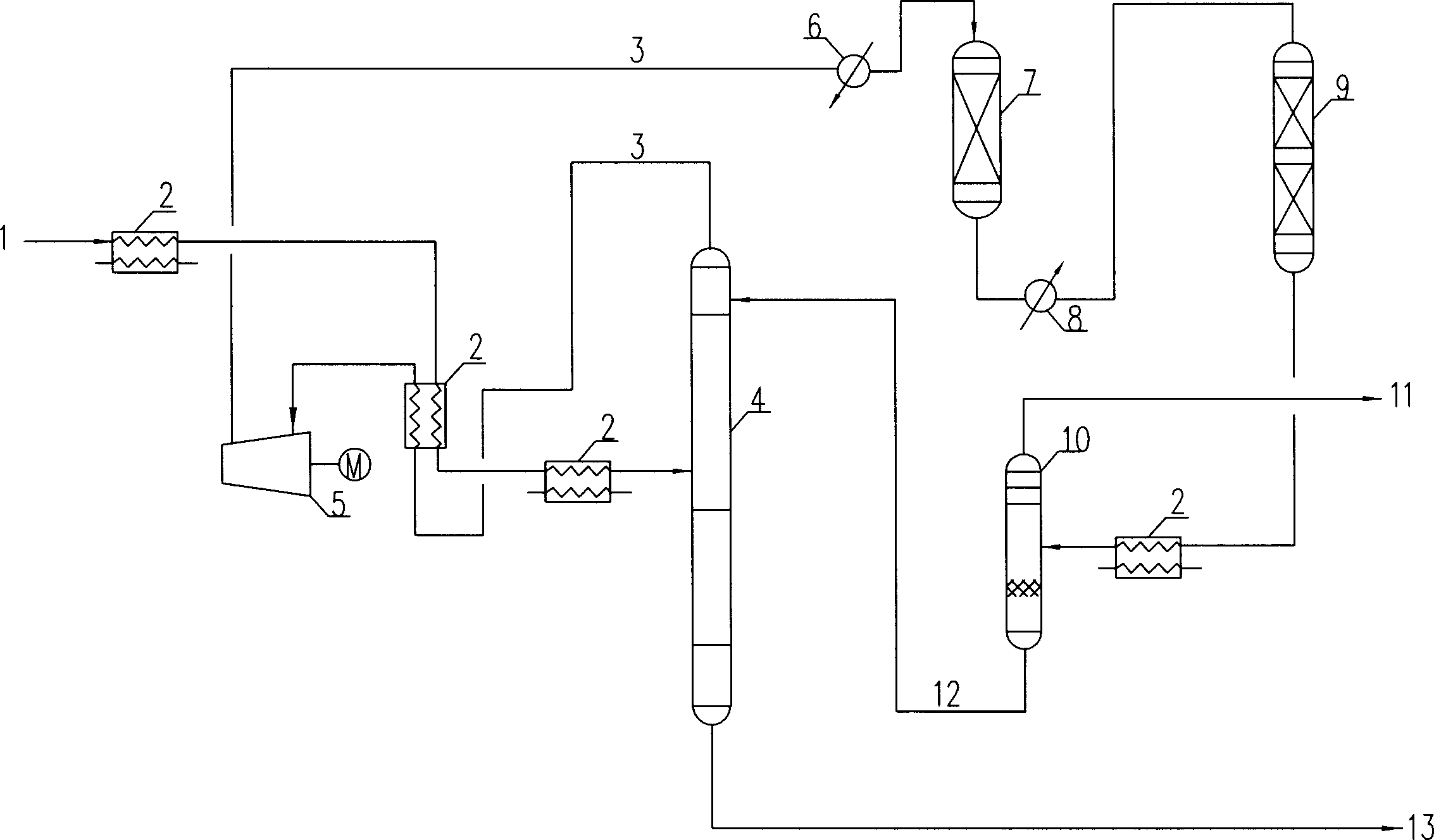

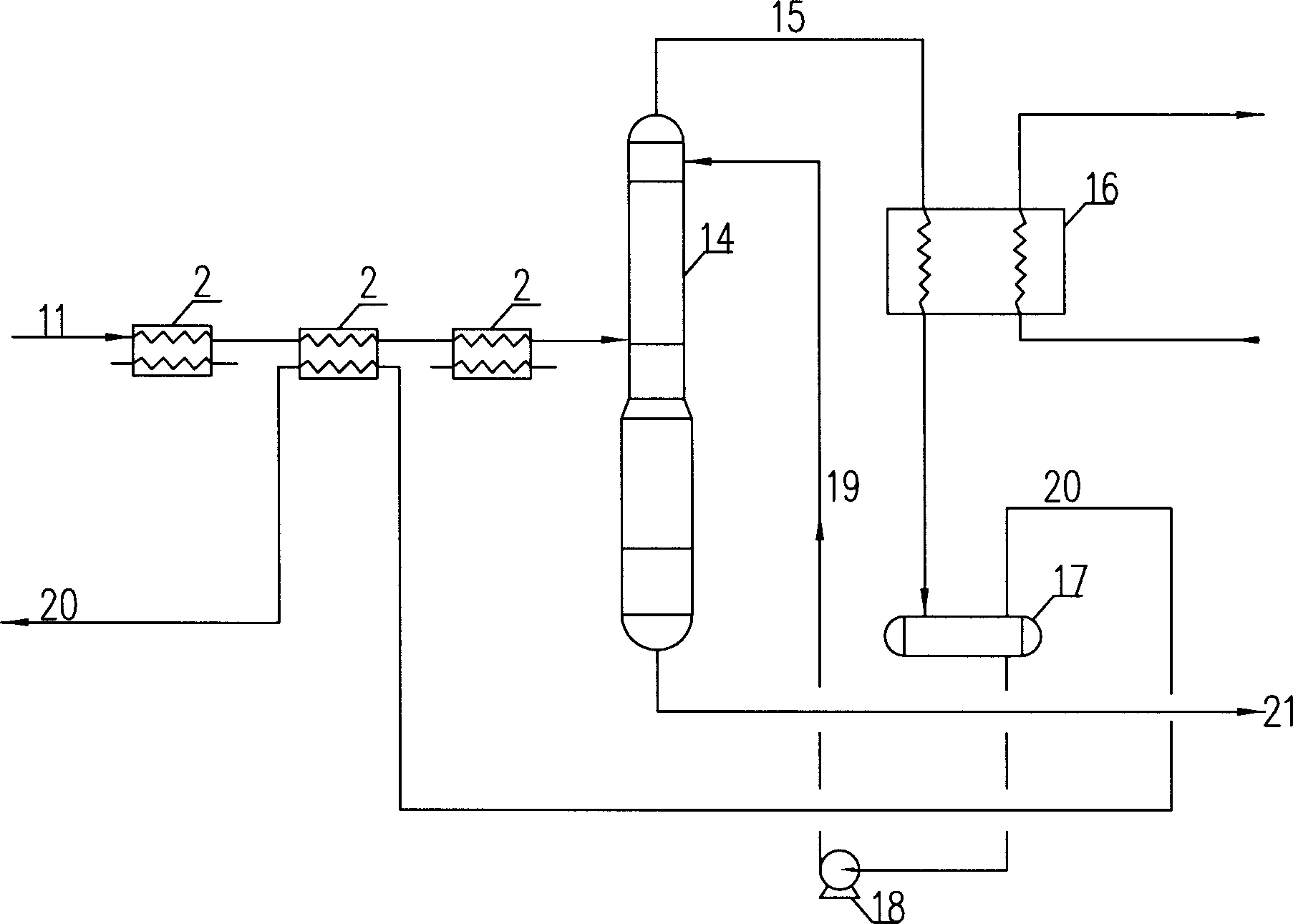

[0021] Such as figure 1 , figure 2 As shown, the DMTO raw material gas 1 is compressed and dried in four stages, the pressure is 2.5~3.5MPa, and then gradually cooled to -10~-20°C by three coolers 2, and enters the deethanizer 4, the deethanizer The purpose of 4 is to remove propylene, propane and heavier fractions in DMTO raw gas 1, avoid propylene, propane and heavier fractions from entering the cold zone, and reduce the power consumption of DMTO gas compressor and refrigeration compressor. The top of the deethanizer 4 separates carbon 2 and light components 3 at the top of the deethanizer below the carbon 2. The light component 3 at the top of the deethanizer first passes through the cooler 2 to exchange heat with the raw gas 1, and then enters the fifth stage of the gas compressor 5 to continue compression, and the pressure reaches 2.5-4.0MPa. The heavy component 13 at the bottom of the deethanizer tower separated from the deethanizer 4 is C3 and above. The heavy compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com