Reactor capable of converting various garbage to biological oil or cement simultaneously in the absence of extra powder

A bio-oil and waste technology, applied in cement production, energy efficiency improvement, solid waste removal, etc., can solve problems such as energy-intensive waste disposal and environmental protection discharge, and achieve good ventilation, normal system operation, and good oxygen-rich environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention should be formed into a unit by 3 to 6 reactors in the concrete implementation process, and this is because the warm-up start of reactor needs to consume a large amount of fuel, and needs continuous production 2 to 3 months after reactor start-up and then enters maintenance period so cycle. A unit composed of multiple reactors is firstly the sharing of fuel and electric energy. In addition, the sharing of waste heat of liquid and gaseous heat carriers and the cascading utilization of thermal energy can improve the energy utilization efficiency of the entire system.

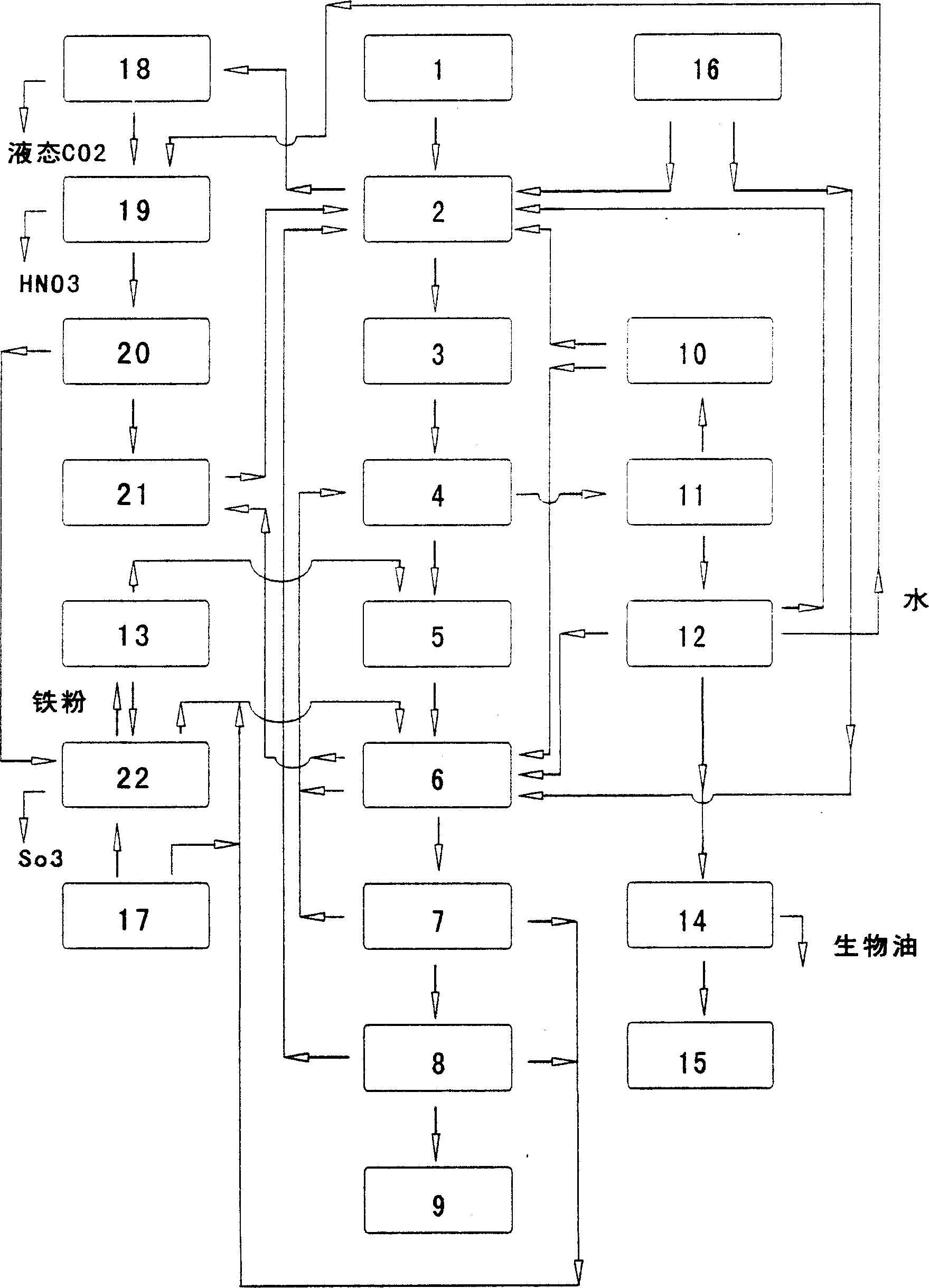

[0108] figure 1It is a schematic diagram of the process principle flow after the reactor warm-up and start-up process, which will be explained separately after the reactor warm-up start-up process. Garbage enters the garbage sorter (1), and other metals such as aluminum and iron are sorted out, and the remainder enters the drying crusher (2). The heat source at this time is the clink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com