A radial compression applied sealing member processing method

A processing method and technology of seals, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as large unevenness of stress state, complex production process, impact cracks, etc., to improve coordination and corrosion resistance , high degree of process automation, the effect of overcoming impact cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

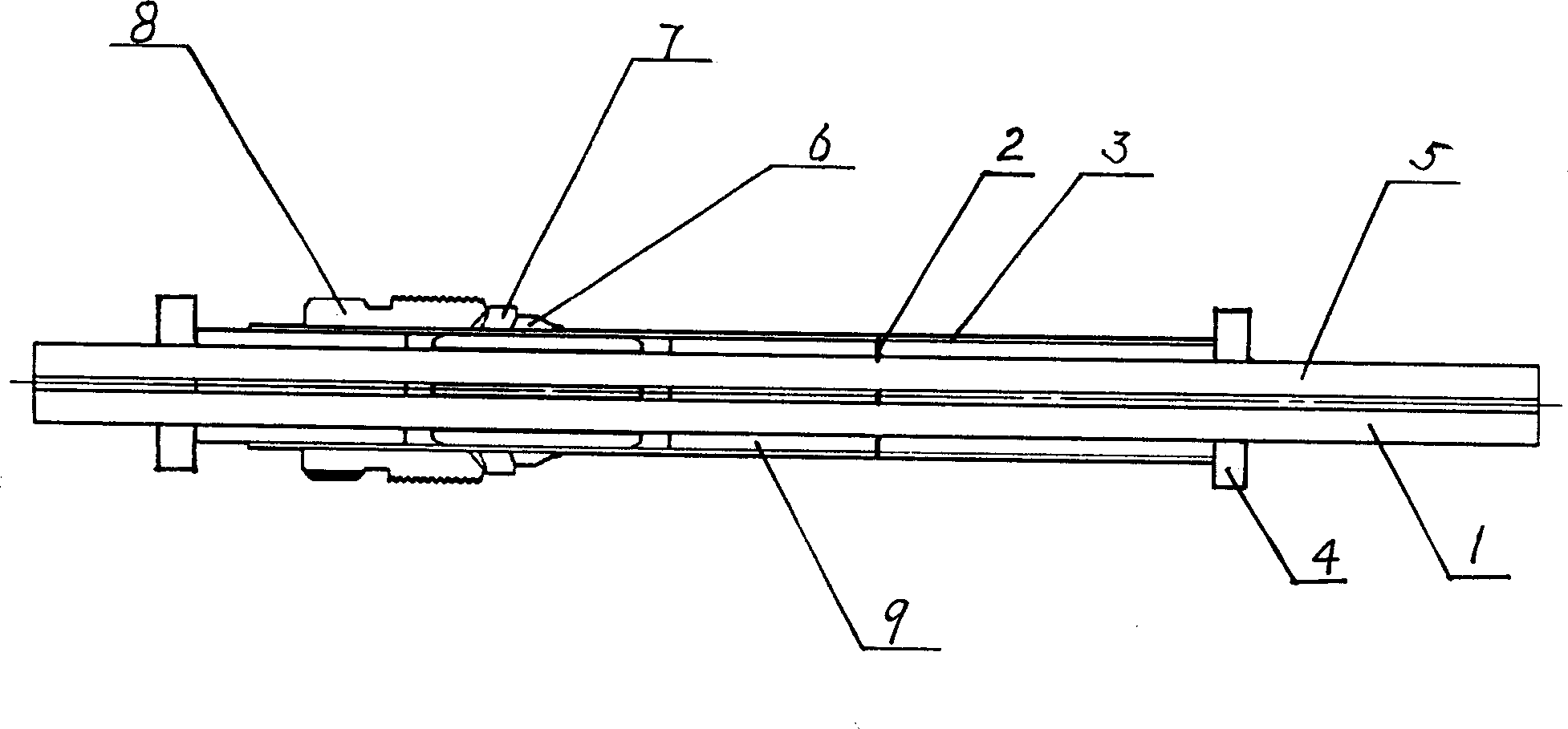

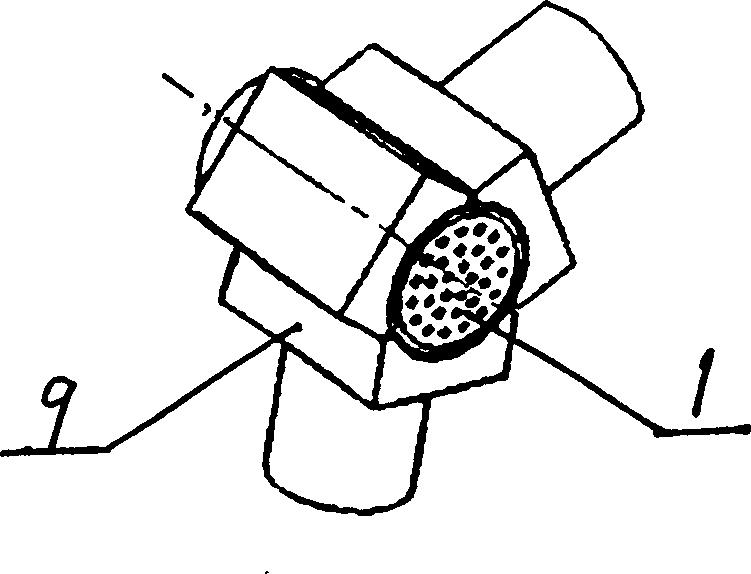

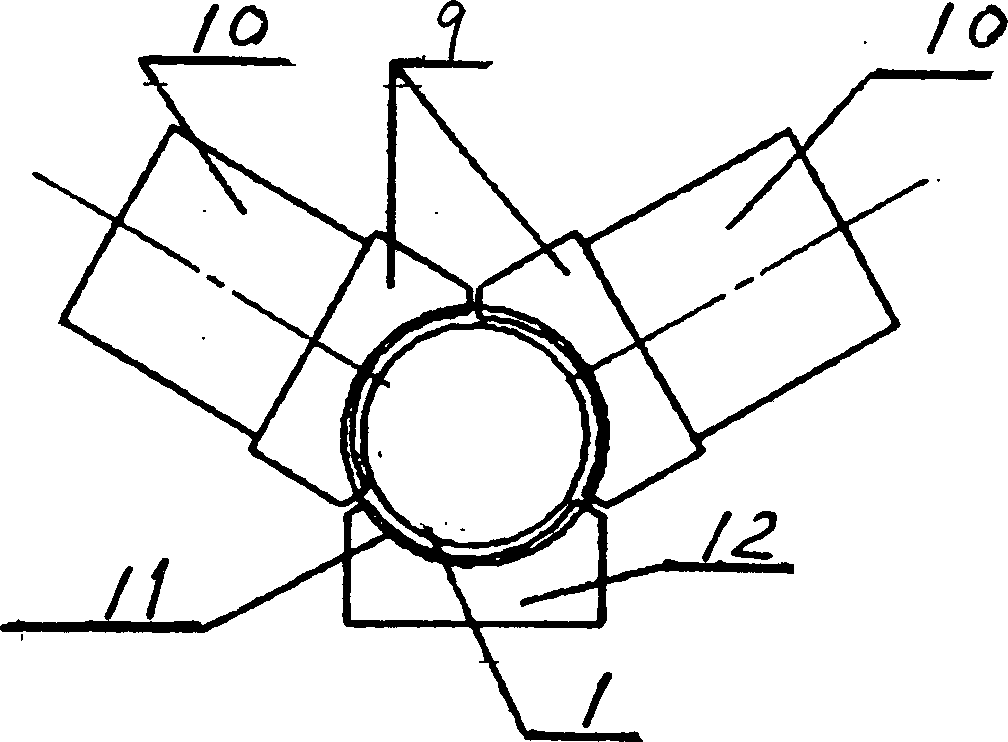

[0026] Such as figure 1 Shown is a schematic diagram of the seal structure,

[0027] (1) First process the seal 1:

[0028] Put the middle partition plate 2 with 14 holes into the metal outer casing 3, and weld the flange 4 with 14 holes at both ends of the metal outer casing 3. The weld seam is treated with fluorocarbon coating to prevent chemical corrosion on the surface. Center the holes of the middle partition 2 and the flange 4, and then put 14 conductors 5 through the holes of the middle partition 2 and the flange 4 into the metal outer sleeve 2, the outer surface of the conductor 5 is covered with insulating material, and the conductor 5 Polysulfone or polyether ether ketone is used to insulate and seal with the metal outer sleeve 3, and finally the two ends of the conductor 5 are respectively covered with an electroless nickel-plated copper sealing ring 6, a guide pressure ring 7 and a compression nut 8. Squeeze and seal with a wrench, and finally install the nitroge...

Embodiment 2

[0034] Annular grooves are formed inside and outside the metal outer sleeve 3, which is more conducive to sealing, and the balanced shrinking deformation force of the sealing member 1 adopts the force produced by air pressure, and other methods remain unchanged.

[0035] The sealing part of the present invention is suitable for nuclear power plants of various scales of 300, 600 and 1000 MW. Due to the adoption of the hydraulic compression diameter sealing technology, the tendency of impact cracks that are easy to occur on the sealing part is effectively solved, and the forming accuracy and mass production quality are improved. stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com