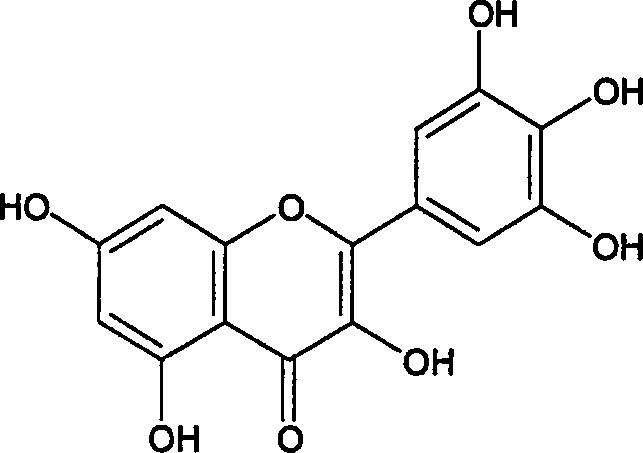

Method for distilling myricetin from plant

A technology of myricetin and red bayberry, applied in the direction of organic chemistry, can solve the problems of difficulty in purifying myricetin, low content, high cost, etc., and achieve the effects of convenient product separation and purification, simple preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, get 1.5kg red bayberry bark and be ground into coarse powder, add 95% ethanol 1500ml heating reflux, each 2 hours, extract altogether 3 times, merge filtrate, filtrate is concentrated to dry, extract is refluxed with ethyl acetate 1500ml 2 times, each time for 1 hour, filter, combine the filtrates, recover the solvent to about 750ml, let stand for 8 hours, filter, and recover the filtrate to dryness under reduced pressure to obtain the crude myricetin. Add 70% ethanol to dissolve the crude myricetin, then add water to adjust the ethanol concentration to 35%, filter, and the filtrate is adsorbed with an adsorption column filled with 30-60 mesh polyamide, and after adsorption, it is carried out with 35% ethanol solution For elution, the eluate was discarded, followed by elution with 65% ethanol solution, and the eluate was collected. After ethanol was recovered from the eluate under reduced pressure, high-purity myricetin was precipitated, filtered, and the ...

Embodiment 2

[0019] Embodiment 2, get 2kg Yao Nationality vine tea stem and leaf and pulverize into coarse powder, add 2000ml of 85% ethanol and heat to reflux, each time 2 hours, extract altogether 3 times, combine filtrate, filtrate is concentrated to dry, extract with ethyl acetate 2000ml Reflux twice, each time for 1 hour, filter, combine the filtrates, recover the solvent to about 1000ml, let stand overnight, filter, and recover the filtrate to dryness under reduced pressure to obtain the crude myricetin. Add 80% ethanol to dissolve the crude myricetin, then add water to adjust the ethanol concentration to 30%, filter, and the filtrate is adsorbed with an adsorption column filled with polyamide, after adsorption, elute with 30% ethanol, discard Remove the eluate, continue to elute with 70% ethanol solution, and collect the eluate. After ethanol was recovered from the eluent under reduced pressure, high-purity myricetin was precipitated, filtered, and the precipitate was collected and ...

Embodiment 3

[0020] Embodiment 3, get 1.5kg red bayberry bark and be ground into coarse powder, add 70% ethanol 1500ml heating reflux, each 2 hours, extract altogether 3 times, merge filtrate, filtrate is concentrated to dry, extract is refluxed with ethyl acetate 1500ml 2 times, each time for 1 hour, filter, combine the filtrates, recover the solvent to about 750ml, let stand for 10 hours, filter, and recover the filtrate to dryness under reduced pressure to obtain the crude myricetin. Add 80% ethanol to dissolve the myricetin crude product, add water to adjust the ethanol concentration to 35%, filter, and the filtrate is adsorbed with an adsorption column filled with D101 macroporous adsorption resin. After adsorption, wash with 38% ethanol solution Remove, discard the eluate, continue to elute with 75% ethanol solution, and collect the eluate. After the eluate was decompressed and recovered the alcohol solution, high-purity myricetin was precipitated, filtered, and the precipitate was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com