Method for the preparation of high purity carbon nanotubes using water

A carbon nanotube, high-purity technology, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems of reduced total yield of carbon nanotubes, affecting the preparation of carbon nanotubes, complicated reactions, etc., to achieve the suppression of soot Formation, reduced soot formation, easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (a) Preparation of catalyst: use Fe(NO 3 ) 2 and Co(NO 3 ) 2 impregnated in an aqueous solution, and then calcined at 300 °C under atmospheric pressure. The catalyst obtained contained 5% by weight each of iron and cobalt.

[0072] (b) Preparation of carbon nanotubes: 0.2 g of alumina catalyst co-impregnated with iron and cobalt prepared in (a) was added to a quartz boat, and then placed in a quartz tube reactor (27 mm in diameter) located in an electric furnace )center of. Then, the temperature of the reactor was raised to 1000° C. with the flow of helium gas at a rate of 100 ml / min. When the temperature of the reactor reached 1000° C., 2 vol % of benzene and 10 vol % of water respectively vaporized from helium were injected into the reactor, followed by carbon nanotube synthesis for 30 minutes.

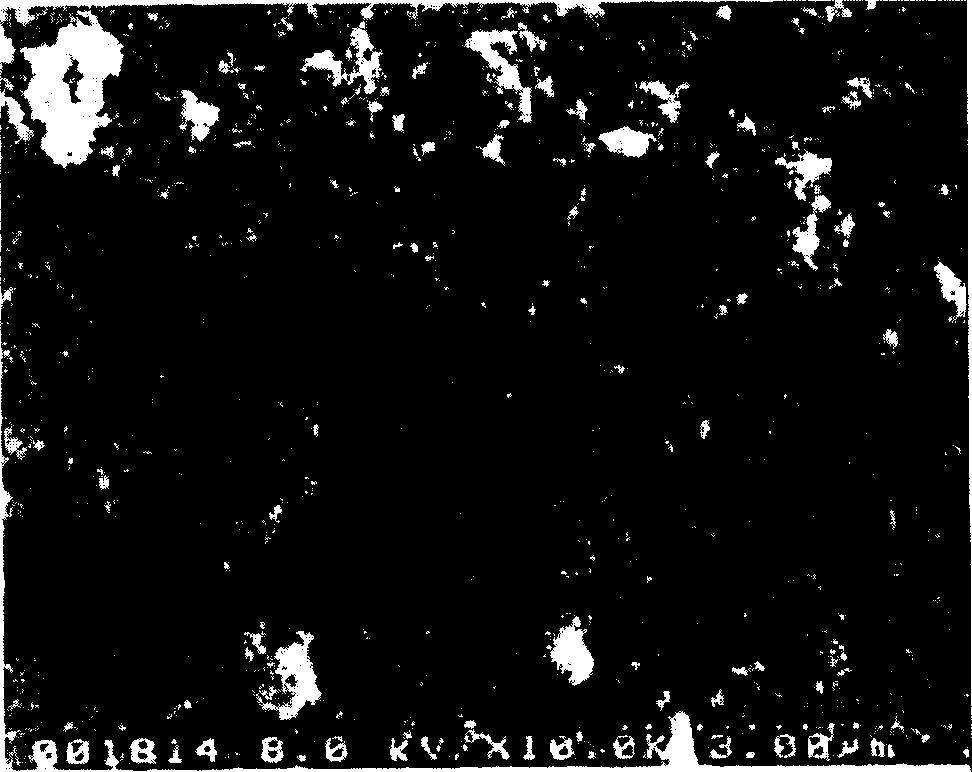

[0073] By analyzing the obtained product using a scanning electron microscope (SEM), the presence of carbon nanotubes mixed with about 20% of soot as an impurity was co...

Embodiment 2

[0075] An emulsion in which benzene nanoparticles were uniformly distributed was prepared by dissolving 5 g of cetyltrimethylammonium bromide (CTAB) in 100 ml of water, after which it was mixed with 10 ml of benzene. 0.2 g of the catalyst prepared in Example 1 was added into a quartz boat, which was then placed in the center of a quartz tube reactor with a diameter of 27 mm. Then, the temperature of the reactor was raised to 1000° C. with the flow of helium gas at a rate of 100 ml / min. When the reactor temperature reached 1000° C., carbon nanotube synthesis was performed for 30 minutes by injecting the benzene emulsion (prepared in the above method) into the reactor at a rate of 0.34 ml / min.

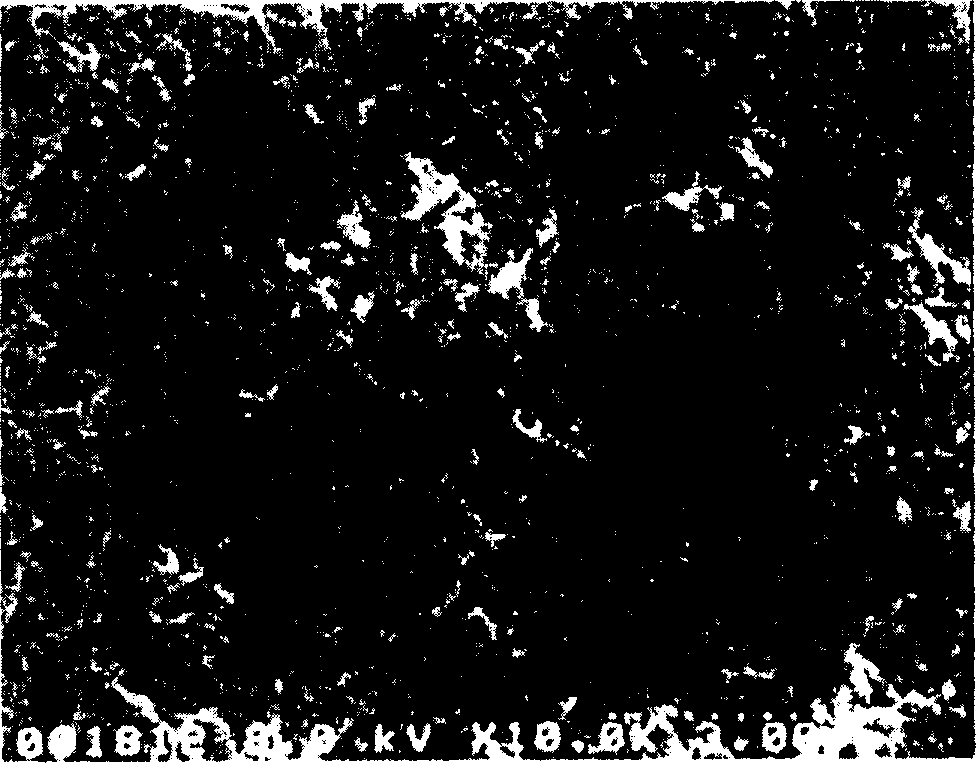

[0076] According to the result of analyzing the obtained product using SEM, it was found that the soot formation was relatively reduced compared with Example 1, but according to the result of analyzing the obtained product using a transmission electron microscope (TEM), it was found that...

Embodiment 3

[0078] Embodiment 3 (comparative example)

[0079] In order to examine the role of water in the preparation of high-purity carbon nanotubes, carbon nanotubes were synthesized by using the same catalyst as in Example 1 under the same reaction conditions. In this example, instead of injecting water, benzene was vaporized to 2% by volume with helium and then injected into the reactor. The reaction was carried out at 1000°C for 30 minutes.

[0080] According to the results of analyzing the obtained product using SEM, it was found that a large number of soot particles coexisted with the carbon nanotubes. Furthermore, according to the results of analyzing the obtained product using TEM, it was found that the average diameter of the carbon nanotubes was about 1.2 nm.

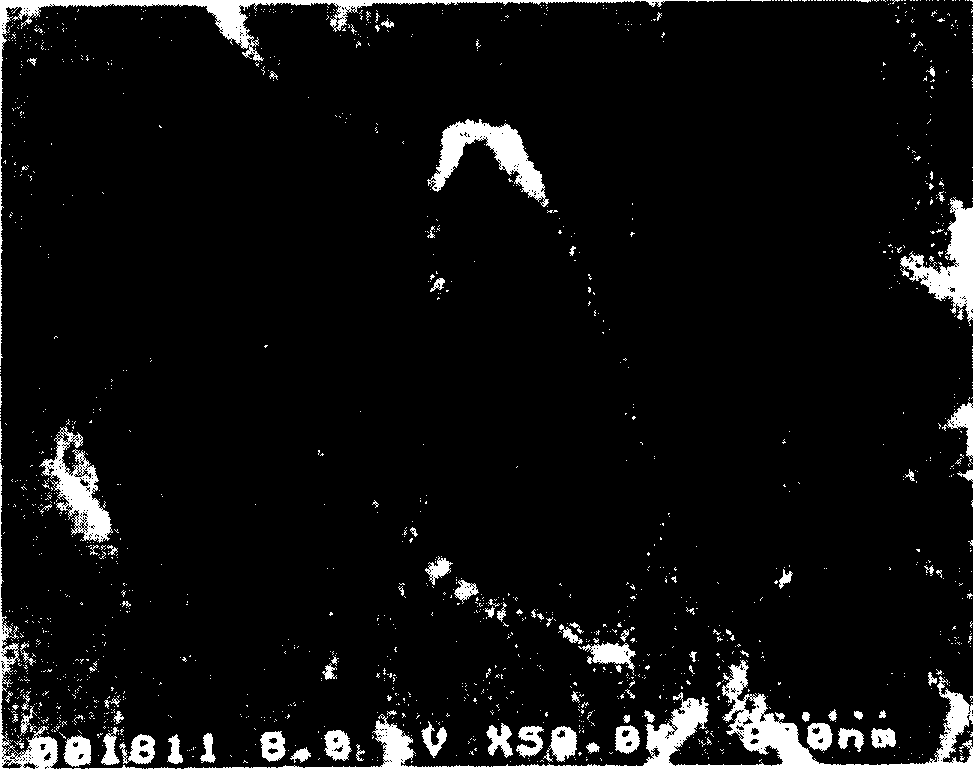

[0081] image 3 is a scanning electron microscope (SEM) image of the carbon nanotubes prepared in Example 3.

[0082] SEM images of carbon nanotubes synthesized by water injection ( figure 1 and figure 2 ), no s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com