Large power continuous wave DCN laser

A laser and high-power technology, applied in the direction of lasers, laser components, laser components, etc., can solve problems such as large gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

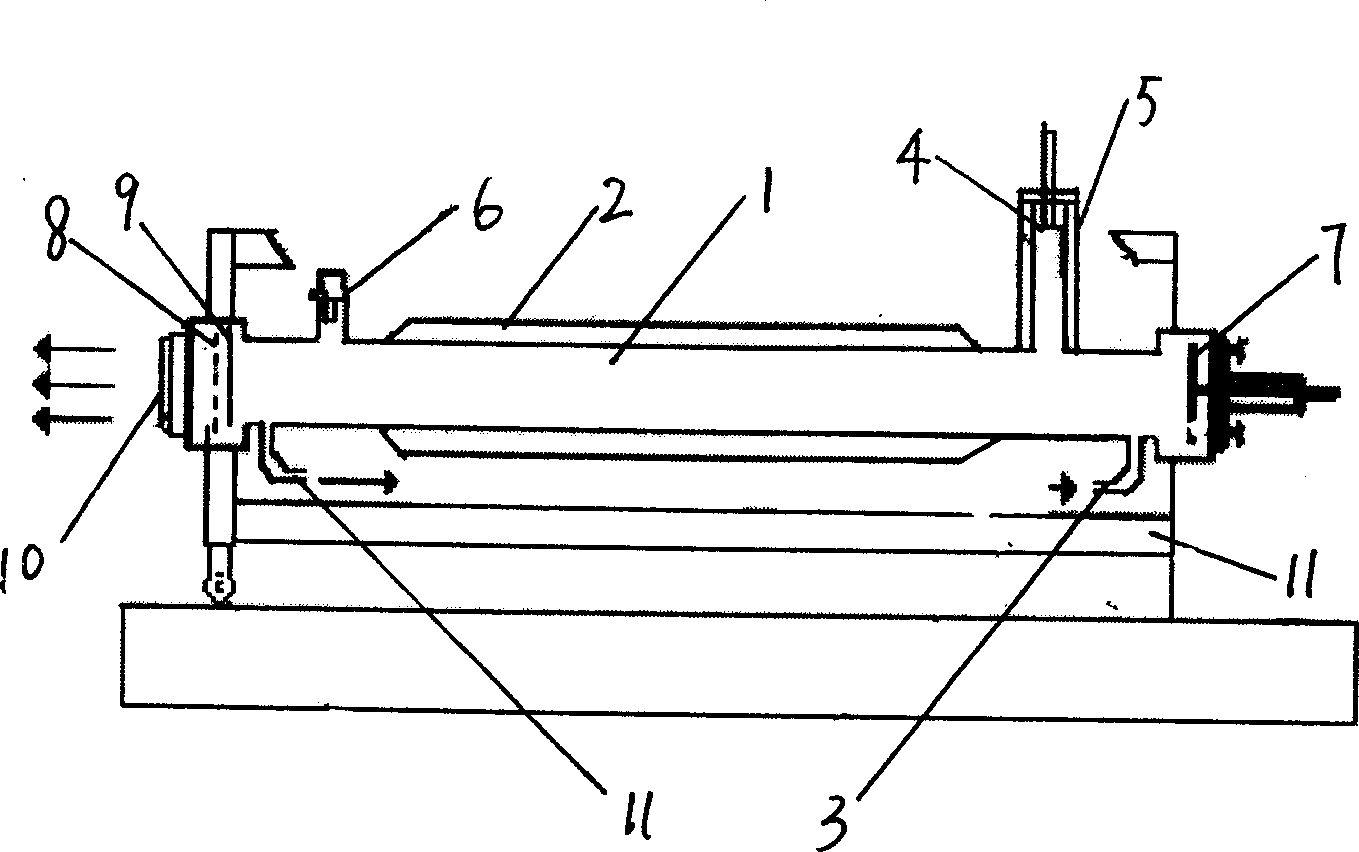

[0021] This is a high-power waveguide far-infrared DCN laser with continuous glow discharge excited by direct current. It consists of the following parts: ① discharge tube 1: the material is 17 # Glass, inner diameter 48mm, outer diameter 54mm, length 3.4m, discharge length 3m. The discharge tube 1 is equipped with an oil cooling jacket 2, and the inside of the jacket is filled with 201 # Methyl silicone oil, the oil temperature is controlled by a super thermostat. ② Electrode: The cathode 4 and the anode 6 of glow discharge are made of brass or other materials, lined with rare metals or their compounds with low sputtering rate, and a water circulation cooling jacket 5 is considered to be installed outside the cathode 4 . In order to prolong the service life of the discharge vessel 1, the cathode 4 is connected to the discharge vessel 1 via a transitional glass tube. ③Power supply: a 20KVA high voltage constant current source, the output current can be continuously adjusted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com