Composite biological medical materials of nano-hydroxy-apatite/silicon rubber and its preparation

A technology of nano-hydroxyapatite and biomedical materials, applied in medical science, prosthesis, etc., can solve the problems of limited mechanical properties and comprehensive biological properties, easy agglomeration, high surface activity of hydroxyapatite, and achieve comprehensive performance Excellent, uniform mixing and distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

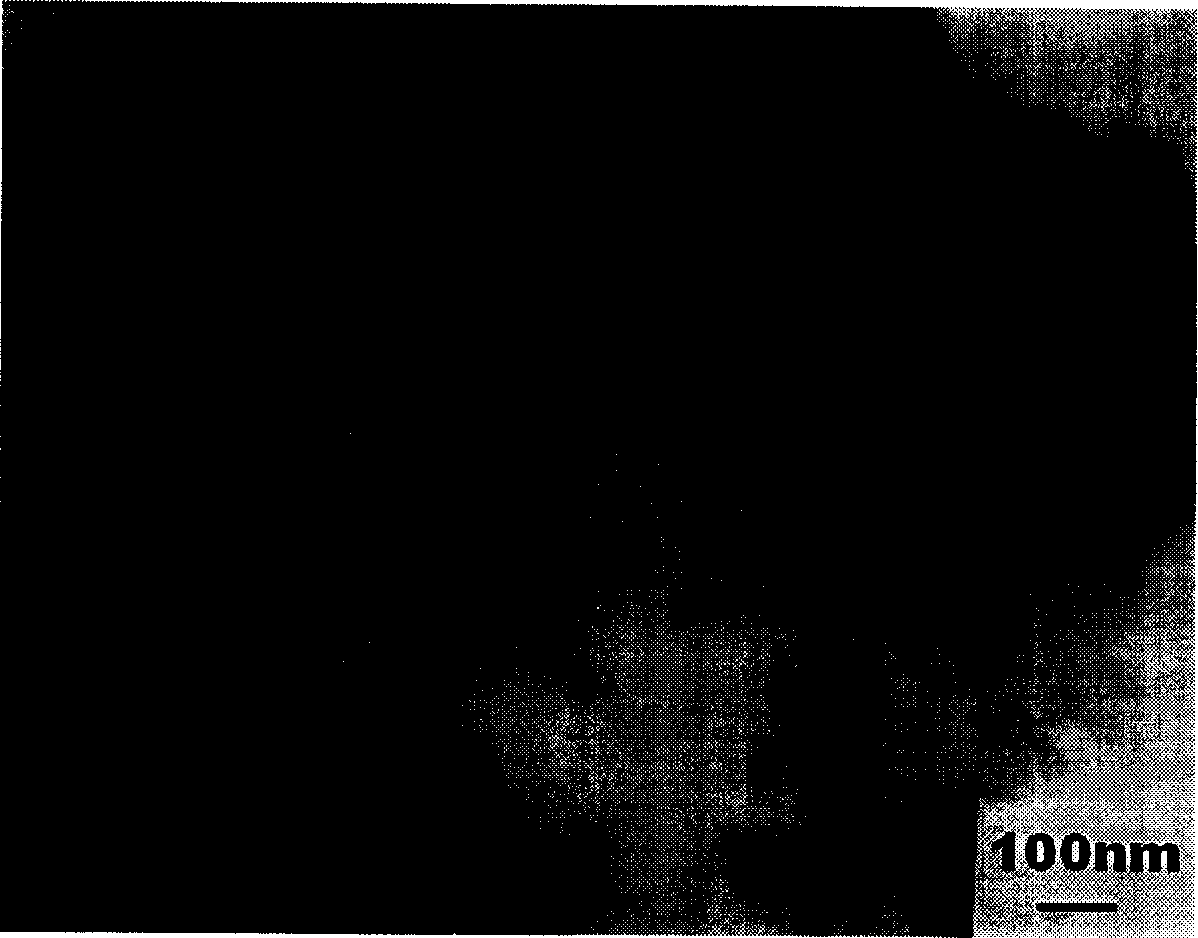

Image

Examples

Embodiment 1

[0029] (1) Preparation of nano-hydroxyapatite slurry: According to the method reported in the aforementioned literature, calcium nitrate and diammonium hydrogen phosphate are reacted at 70 ° C, and the pH value is adjusted to 10-12 with ammonia water to obtain hydroxyapatite After the initial deposit, rinse thoroughly with deionized water. The initial sediment was hydrothermally treated at 140° C. and 0.3 MPa for 2 hours, and then part of the water was removed by centrifugation to obtain a nano-hydroxyapatite component slurry with a solid weight of 30%.

[0030] (2) With hydroxyapatite weight 2% vinyltriethoxysilane 60g as silane coupling agent, add in the 2kg ethanol-water solution that has adjusted pH value to 4.5, ethanol content (weight) 20% with acetic acid, It is formulated as a treatment solution for surface modification treatment of nano-hydroxyapatite components.

[0031] (3) Surface modification treatment on the nano-hydroxyapatite component: add the above-mentioned...

Embodiment 2

[0035] Operation mode and condition are the same as embodiment 1.

[0036] Get nano-hydroxyapatite composition and be 4.5kg slurry (solid matter weight content is 40%), take the vinyl triethoxysilane of 1% by weight of hydroxyapatite composition as silane coupling agent, adjust with acetic acid Surface modification treatment was carried out at 45° C. in 6.7 kg of water-ethanol solution with a pH value of 3.5 and an ethanol content (weight) of 30%. The slurry after the surface modification treatment was washed with deionized water, and mixed with 10.5 kg of methyl vinyl silica raw rubber (the weight ratio of nano-hydroxyapatite to methyl vinyl silica raw rubber was 3:7) in rubber mixing After kneading in the machine at room temperature, the mixed rubber was heated in an oven at 120°C for 1 hour. Add 63 g of vulcanizing agent 2,5-dimethyl-2,5-di-tert-butylperoxyhexane in the proportion of 0.6% of raw rubber weight in the mixed rubber to vulcanize, and obtain nano-hydroxyapatite...

Embodiment 3

[0038] Operation mode and condition are the same as embodiment 1.

[0039] Get nano-hydroxyapatite composition and be 6kg slurry 20kg, take hydroxyapatite weight 4wt% vinyltriethoxysilane 240g as silane coupling agent, add the 4kg ethanol that has adjusted pH value to 5.5 with acetic acid- In the aqueous solution, stir at 55°C for surface modification treatment. After the modified slurry was washed with deionized water, it was mixed with 9 kg of methyl vinyl silicon raw rubber (the weight ratio of nano-hydroxyapatite to methyl vinyl silicon raw rubber was 4:6) in the rubber mixer After medium mixing, 135 g of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane curing agent was added at a ratio of 1.5% by weight of the raw rubber in the mixed rubber for vulcanization treatment. A nano-hydroxyapatite / silicone rubber composite biomedical material with a weight ratio of nano-hydroxyapatite and silicone rubber of 4:6 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com