Process for producing fire-retarded corrugated paper honeycomb material for engineering

A production process, honeycomb material technology, applied in the direction of paper, machining/deformation, etc., can solve the problems of waste of corrugated machinery feeding rate, high difficulty, low production efficiency, etc., to improve investment cost performance, flame retardant performance guarantee, replacement The convenient effect of the saw blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

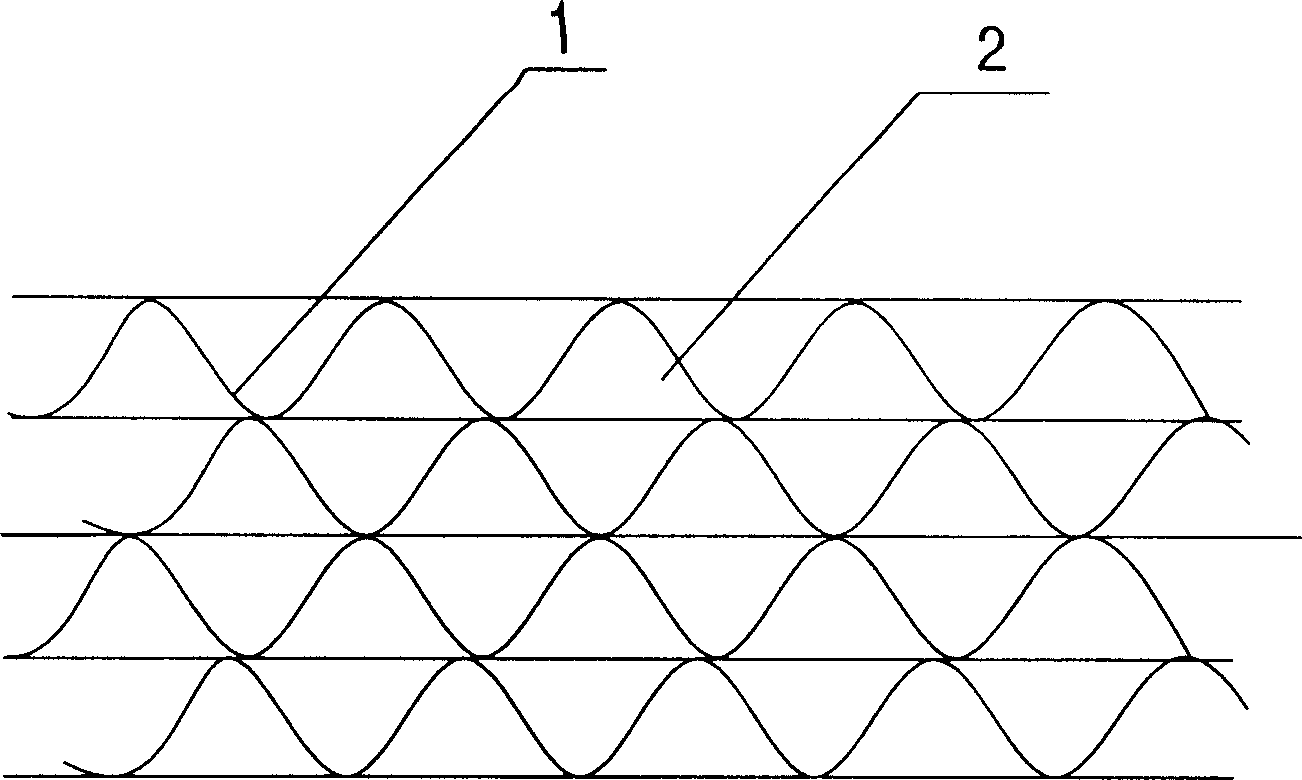

Image

Examples

Embodiment 1

[0020] The weight is 150g / m 2 Ordinary corrugated paper with a width of 160cm and modified starch glue are used to make single-sided or multi-layer corrugated cardboard. These cardboards are cut to length into cardboards with a length of 600cm, and then compounded into composites in sequence with glue coating by a gluing machine, with a thickness of 20cm. When the composite thickness cannot be achieved at one time, it can be composited by multiple pieces. For example, 6 composites with a thickness of 20cm are composited into a composite with a thickness of 120cm, and the corrugated honeycomb composite with a thickness of 120cm (thickness) × 600cm (length) × 160cm (width) is fixed in the mold, impregnated In the sodium silicate solution at 40 degrees in Baume, an enhanced waterproofing agent can be mixed as needed. When impregnating, the complex must be completely impregnated in it. The impregnating time is 5-30 minutes, then drip all the excess liquid, enter the drying room, ...

Embodiment 2

[0022] According to the technique of embodiment one, utilize grammage 170g / m 2 The corrugated paper is made of single-sided or multi-layer corrugated board with polyvinyl alcohol adhesive, and then combined into a corrugated honeycomb composite in turn. The complex is impregnated with a fire retardant solution with a weight ratio of PVC liquid resin:triaryl phosphate ester:ammonium molybdate=95:3:2. The technical indicators of corrugated honeycomb composite panels with a thickness of 3cm are as follows: flat compressive strength ≥ 10MPa, oxygen index OI ≥ 32, smoke density level ≤ 50, good water resistance > 2h. Its comprehensive index can reach hexagonal FRP honeycomb, and the comprehensive cost is much lower than that of FRP honeycomb.

Embodiment 3

[0024] According to embodiment one process. The flame retardant uses water-soluble phenolic resin. The drying temperature after impregnation can be set at 100-120 degrees, and after drying for 3 hours, take out the sawing machine and slice. The technical indicators of the obtained corrugated honeycomb composite panel are as follows:

[0025] Flat compressive strength ≥ 8MPa, oxygen index OI ≥ 35, smoke density level ≤ 46, good water resistance > 2h. The fire resistance limit of the interior wall panel made of calcium silicate board or magnesium oxide board with a thickness of 10mm is ≥ 1.2h according to GB / T9978-1999.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flat compressive strength | aaaaa | aaaaa |

| Flat compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com