MEMS micro high sensitivity magnetic field sensor and manufacturing method

A magnetic field sensor, high-sensitivity technology, applied in the size/direction of the magnetic field, the use of magneto-optical equipment for magnetic field measurement, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

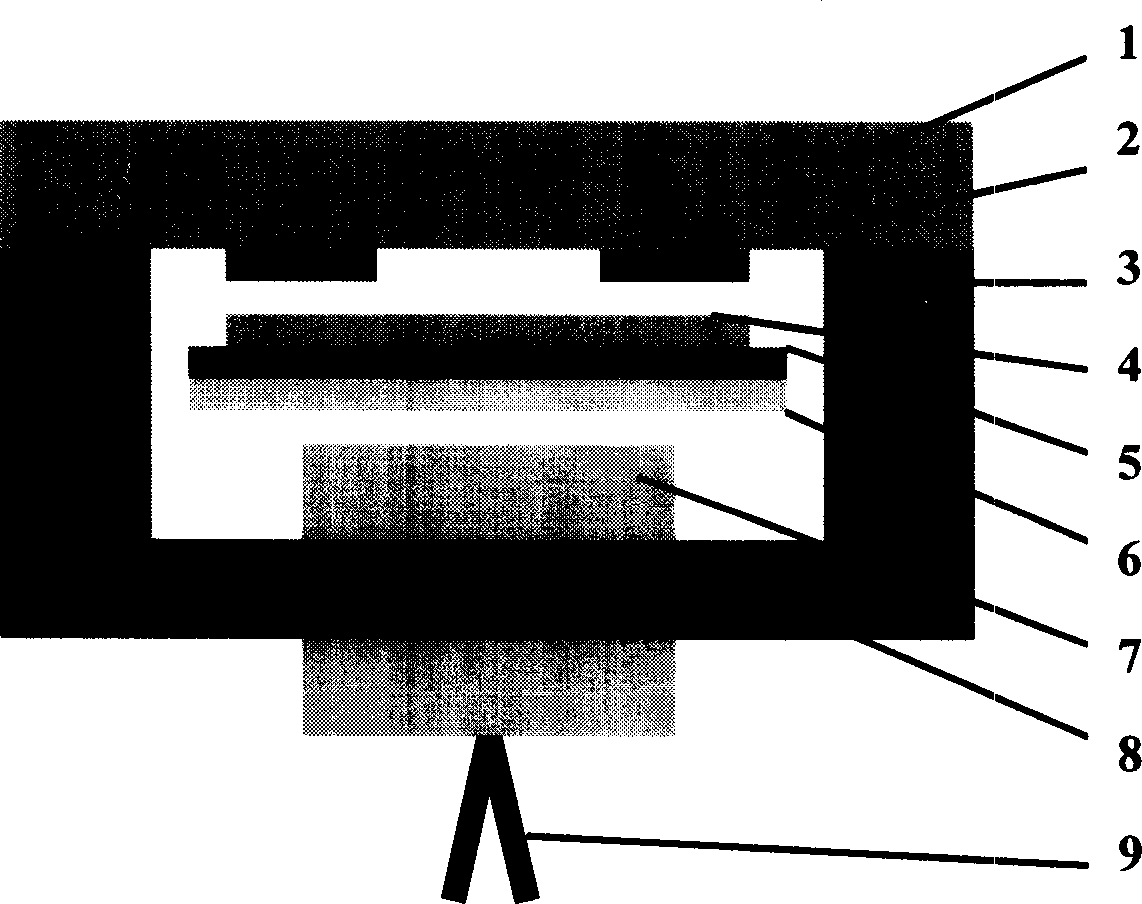

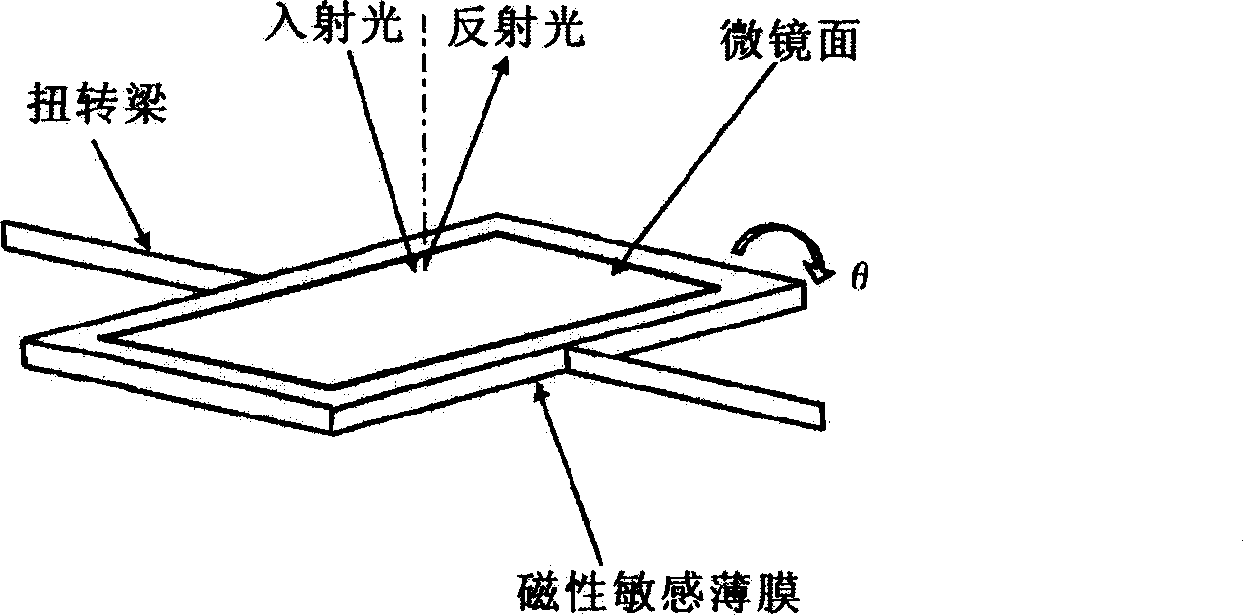

[0098] Embodiment: The specific process implementation method of MEMS high-sensitivity magnetic field sensor is as follows:

[0099] (1) First, on the Pyrex7740 glass support body 1, the metal aluminum electrode material 2 is evaporated by sputtering or electron beam, such as image 3 (b) shown.

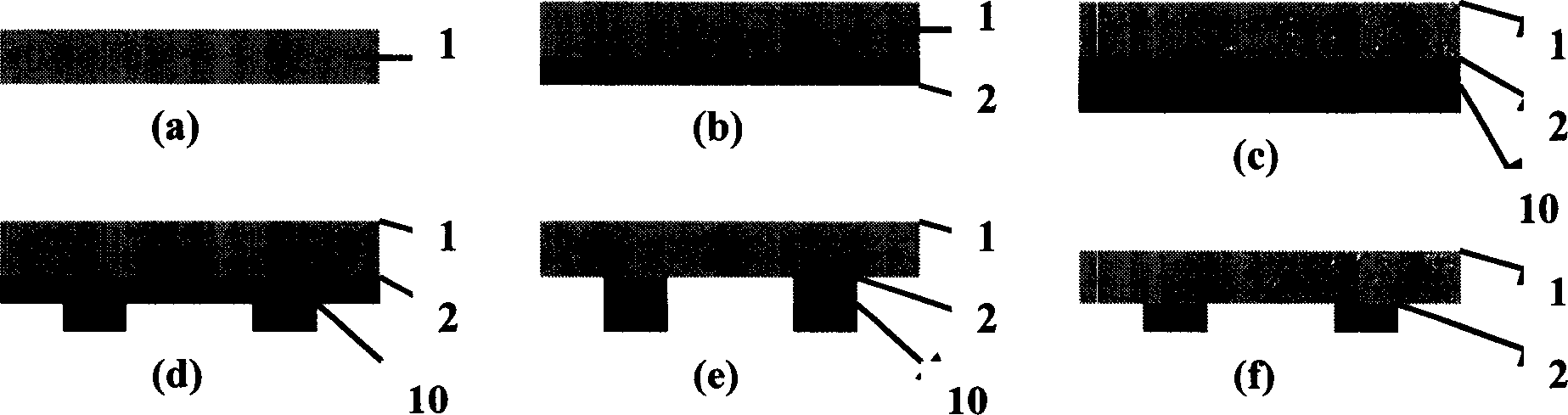

[0100] (2) Select semiconductor materials such as silicon wafer 1 (ordinary P+ type (100) double throw silicon wafer ( Figure 4 a), the thickness is 420±20 microns, the resistivity is 0.01-0.02 ohm cm), and the glue is applied ( image 3 c), photolithography development ( image 3 d) After that, by corrosion ( image 3 e), to glue ( image 3 f) and other processes to realize the patterned production of the feedback electrode 2 .

[0101] (3) By etching on the substrate silicon, SOI or other materials ( Figure 4 a) Upper glue ( Figure 4 b), photolithography and development to get as Figure 4 (c) The patterned mask shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com