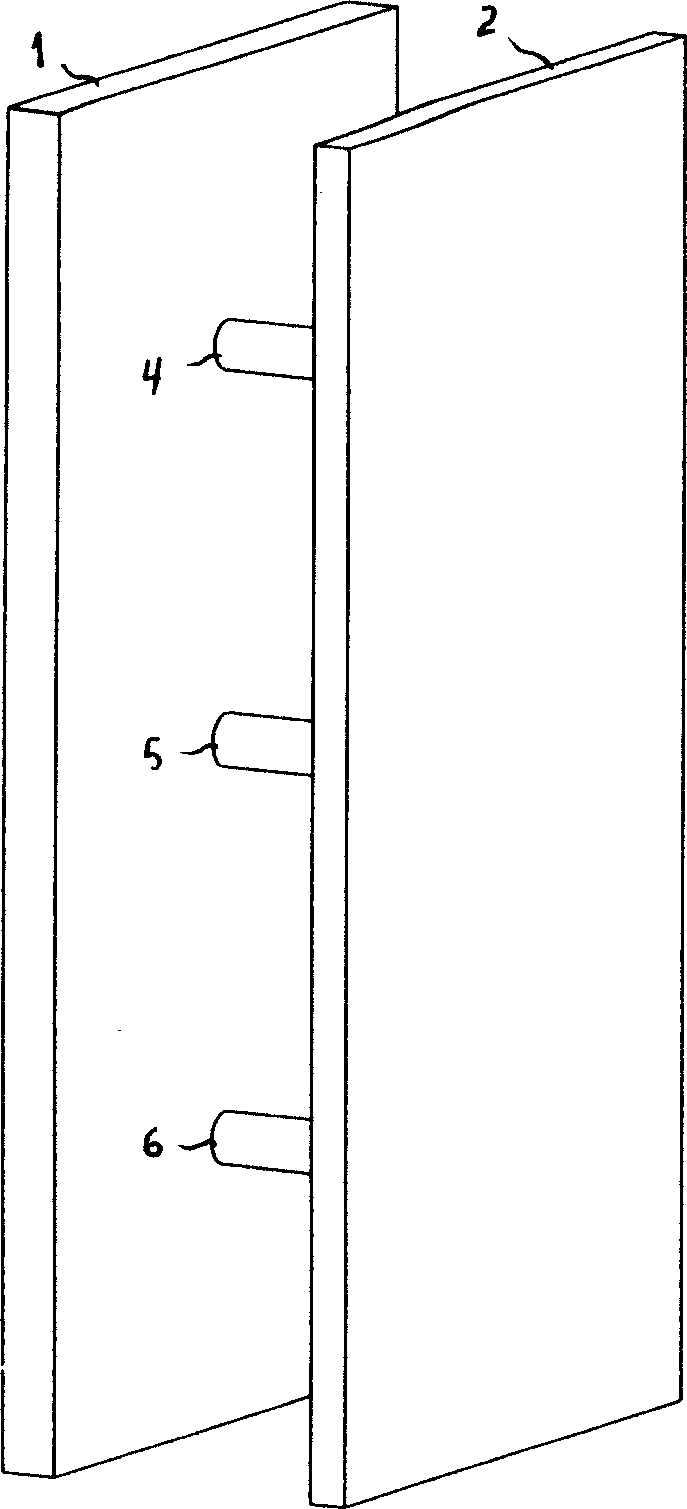

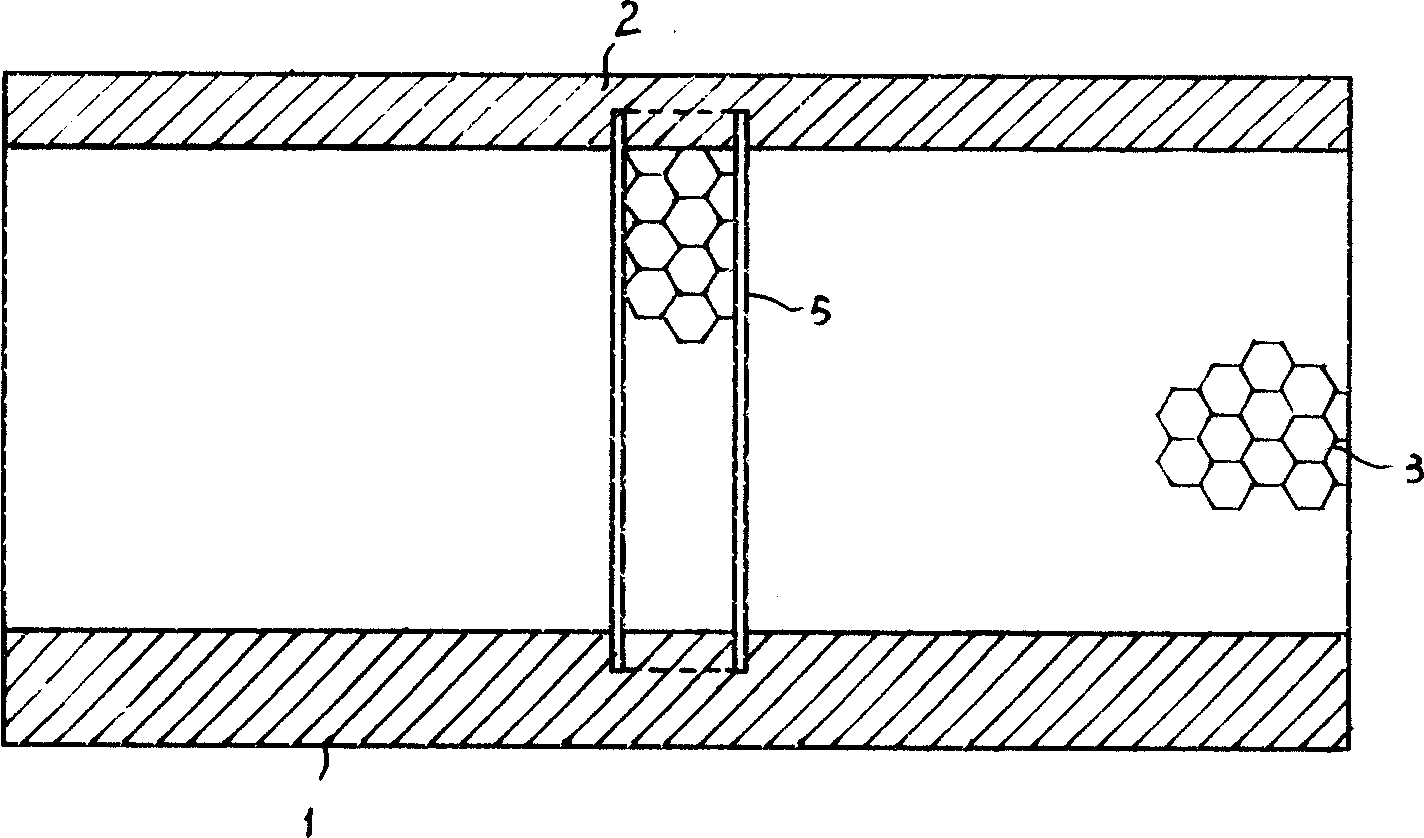

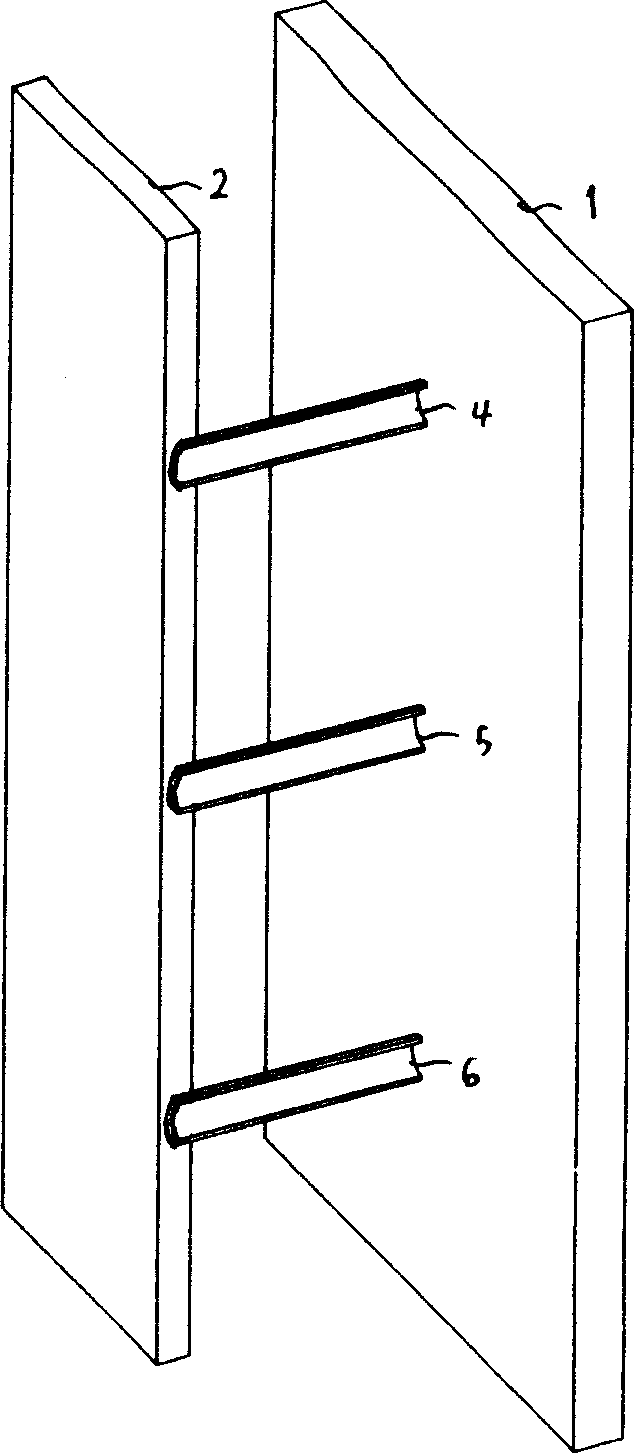

Lightweight heatproof porous wall material and building blocks

A technology for wall materials and thermal insulation blocks, which is applied in the field of block manufacturing, can solve problems such as complicated construction, poor thermal insulation effect, and large capacity, and achieve good thermal insulation effect, small bulk density, and high extrusion strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the wall body material of the present invention, each component weight part is as follows:

[0025] 20 parts of Portland cement; 10 parts of lightly burned magnesia; 5 parts of hydrogen peroxide as foaming agent and 5 parts of rosin sodium soap; 2 parts of calcium stearate and 1 part of naphthalene as stabilizer; 10 parts of plant straw powder . 25 parts of water.

Embodiment 2

[0027] In the wall body material of the present invention, each component weight part is as follows:

[0028] 25 parts of Portland cement; 12 parts of lightly burned magnesia; 7 parts of hydrogen peroxide as foaming agent and 6 parts of rosin sodium soap; 4 parts of calcium stearate and 2 parts of naphthalene as stabilizer; 12 parts of wood flour; water 30 servings.

Embodiment 3

[0030] In the wall body material of the present invention, each component weight part is as follows:

[0031] 35 parts of Portland cement; 16 parts of lightly burned magnesia; 8 parts of hydrogen peroxide as foaming agent and 8 parts of rosin sodium soap; 5 parts of calcium stearate and 3 parts of naphthalene as stabilizer; 16 parts of plant straw powder ; 33 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com