Electrode for electrolysis and method of manufacturing electrode for electrolysis

A manufacturing method and electrode technology, which are applied to electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of low ozone efficiency and difficulty in using ozone water with high efficiency, and achieve the effect of improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

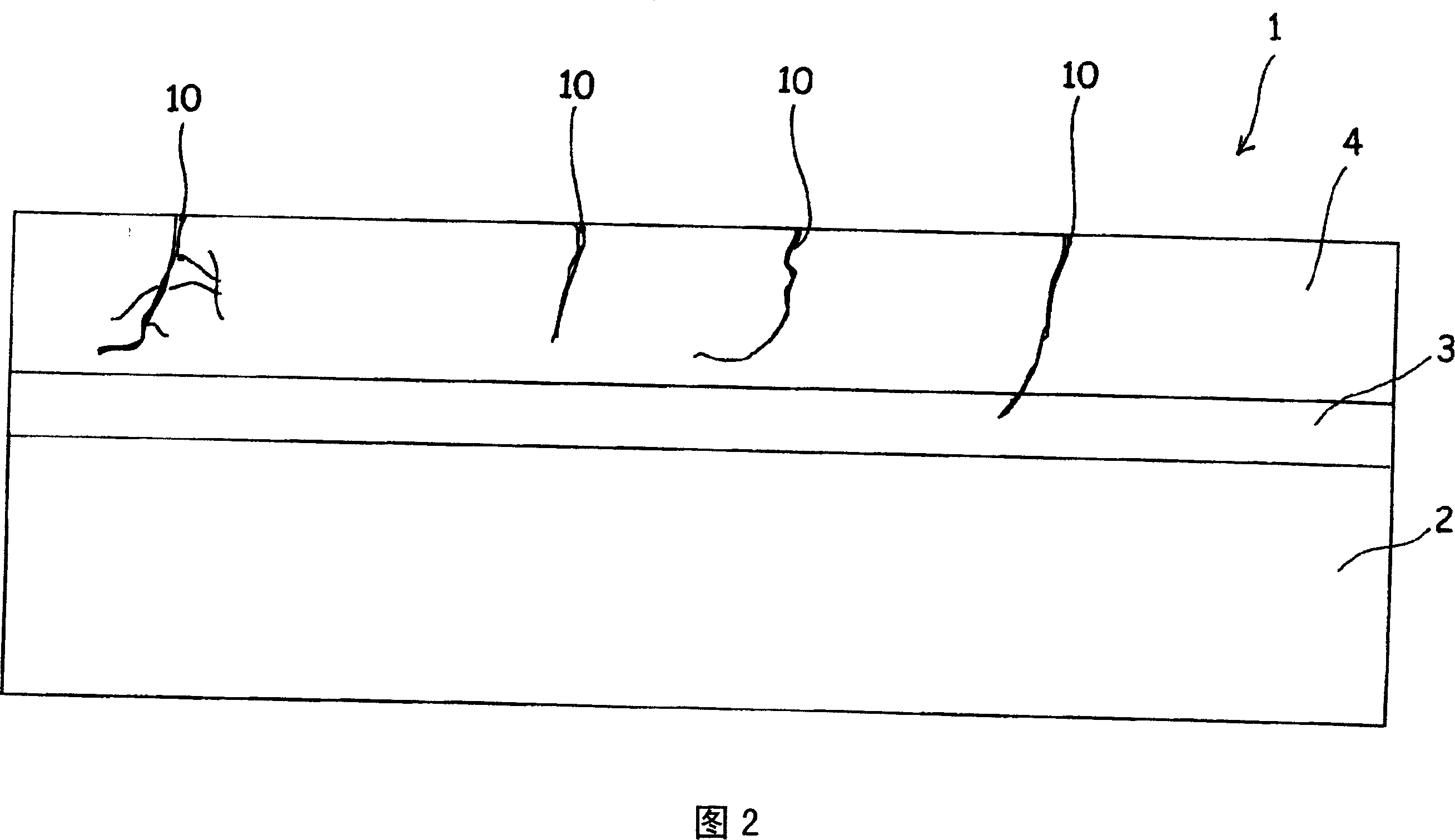

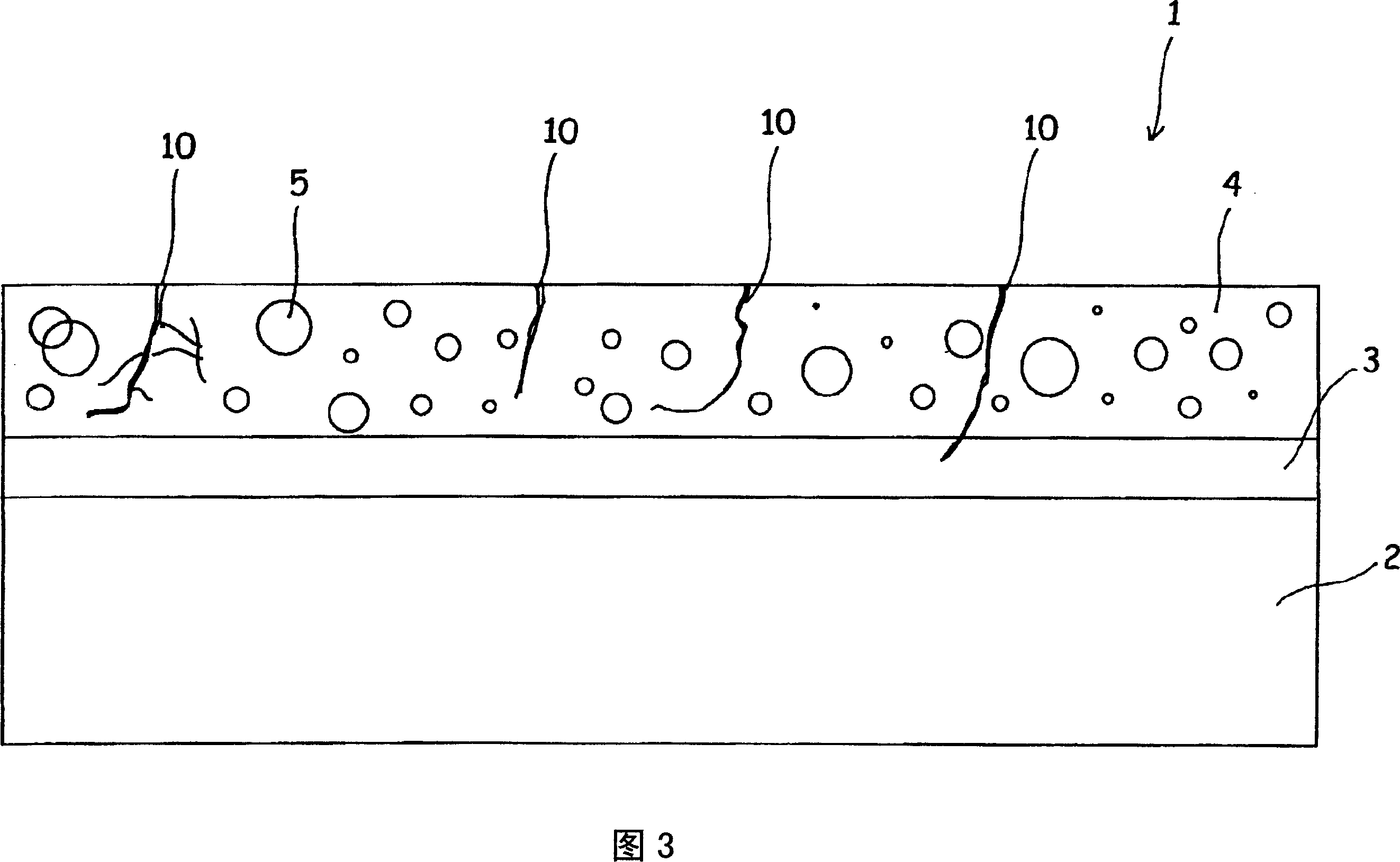

[0050] Hereinafter, the manufacturing method of the electrode for electrolysis of the present invention will be described with reference to the flowchart of FIG. 4. This manufacturing method is a method of covering and forming the intermediate layer 3 on the surface of the conductive substrate 2, and then covering and forming the surface layer 4 on the surface of the intermediate layer 3.

[0051] First, a titanium plate having a thickness of 1 mm, a length of 80 mm, and a width of 20 mm is used as the conductive substrate 2, and the surface of the conductive substrate 2 (a surface with a length of 80 mm and a width of 20 mm) is polished with a paper file (step S1). In addition, in the ozone generating electrode 1 of this embodiment, only one side of the surface of the conductive substrate 2 is covered with the intermediate layer 3 and the surface layer 4, and the surface layer 4 faces the counter electrode and is used as a reaction surface for electrolysis However, when the ozone...

Embodiment 2

[0093] Next, other embodiments of the present invention will be described. When the ozone generating electrode 1 of this example is compared with the example 1, it is different in the following aspects. That is, in the surface layer 4 of the example 1, instead of tantalum oxide, aluminum oxide, titanium oxide, or oxide is used. Tungsten.

[0094] In addition, in the first embodiment, since tantalum oxide is used to form the surface layer 4, the following materials are used as the surface layer constituent materials, that is, the mixing ratio of n-butyl acetate and dimethylformamide is respectively 95 In the solvent adjusted by the method: 5, a solution of tantalum ethoxide in an amount such that the tantalum concentration reaches 1.45 mol / l is dissolved. In contrast, in this embodiment, when aluminum oxide is used to form the surface layer 4, isoamyl acetate is used as a solvent, and a solution in which an organic metal containing aluminum (Al) is dissolved is used as the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com