Method of preparing marsh gas from spartina alterniflora

A technology of Spartina alterniflora and fermentation method, which is applied in the field of resources and environment, and can solve problems such as pollution, large manpower and material resources, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

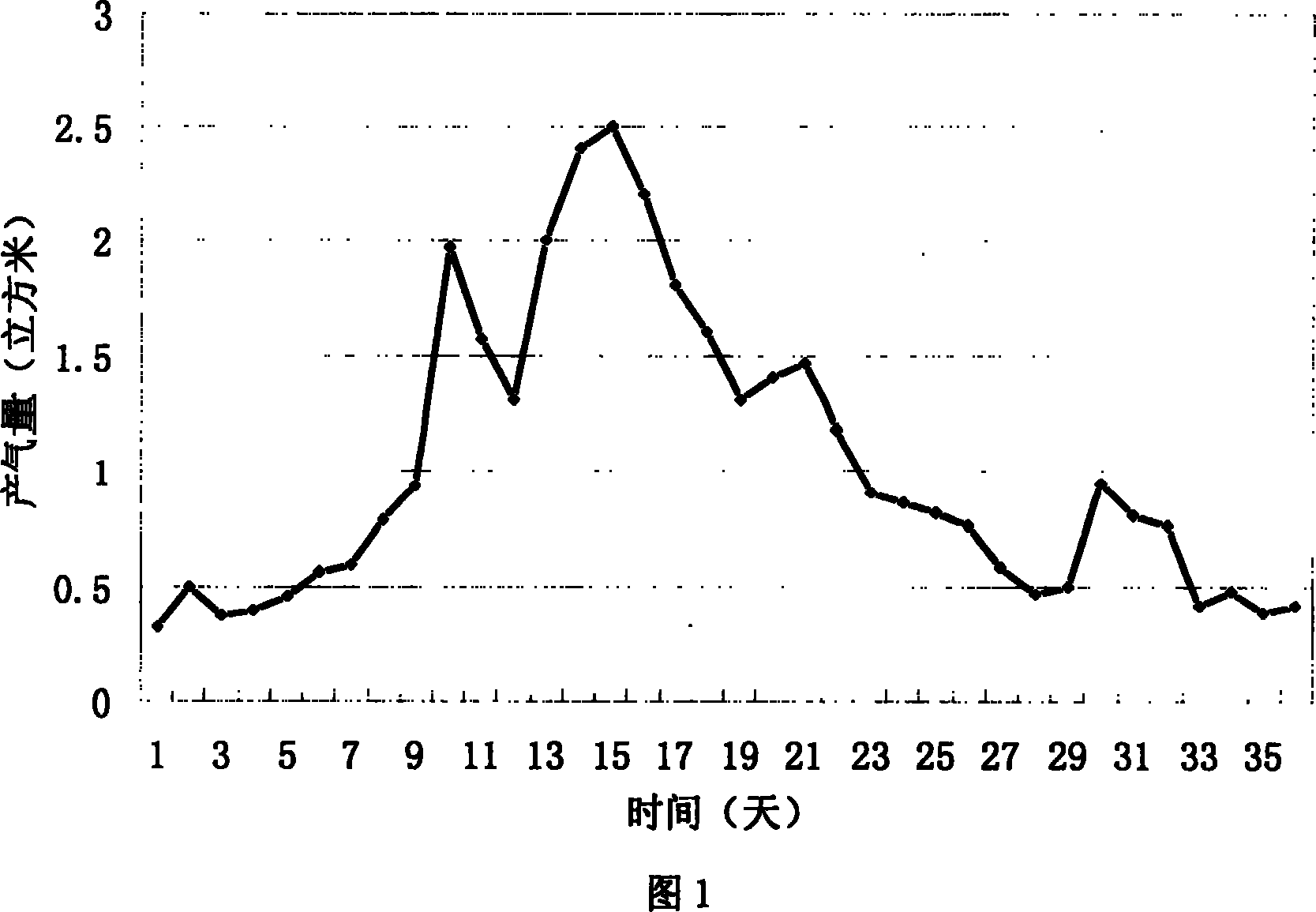

[0028] A farmer uses Spartina alterniflora to prepare biogas.

[0029] (1) Pretreatment of the raw material Spartina alterniflora; cutting the harvested aboveground part of Spartina alterniflora into small sections of 2-3 cm by manual or mechanical means;

[0030] (2) Add 5 kg of N-containing material urea to the Spartina alterniflora 250 kg obtained in step (1), mix, adjust the carbon-nitrogen ratio of the mixture, and make the C / N in the mixture be 20: 1;

[0031] (3) Put the mixed material obtained in the step (2) into a common biogas fermentation device of 4 cubic meters, and add 500 kg of anaerobic digested sludge with an inoculum water content of 80%, to obtain fermentation raw materials;

[0032] (4) add water to the fermented raw material in step (3), until the water surface is higher than fermented raw material 5cm;

[0033] (5) Close the fermentation device, the gas outlet of the fermentation device is connected to the gas storage device through the gas pipeline, an...

Embodiment 2

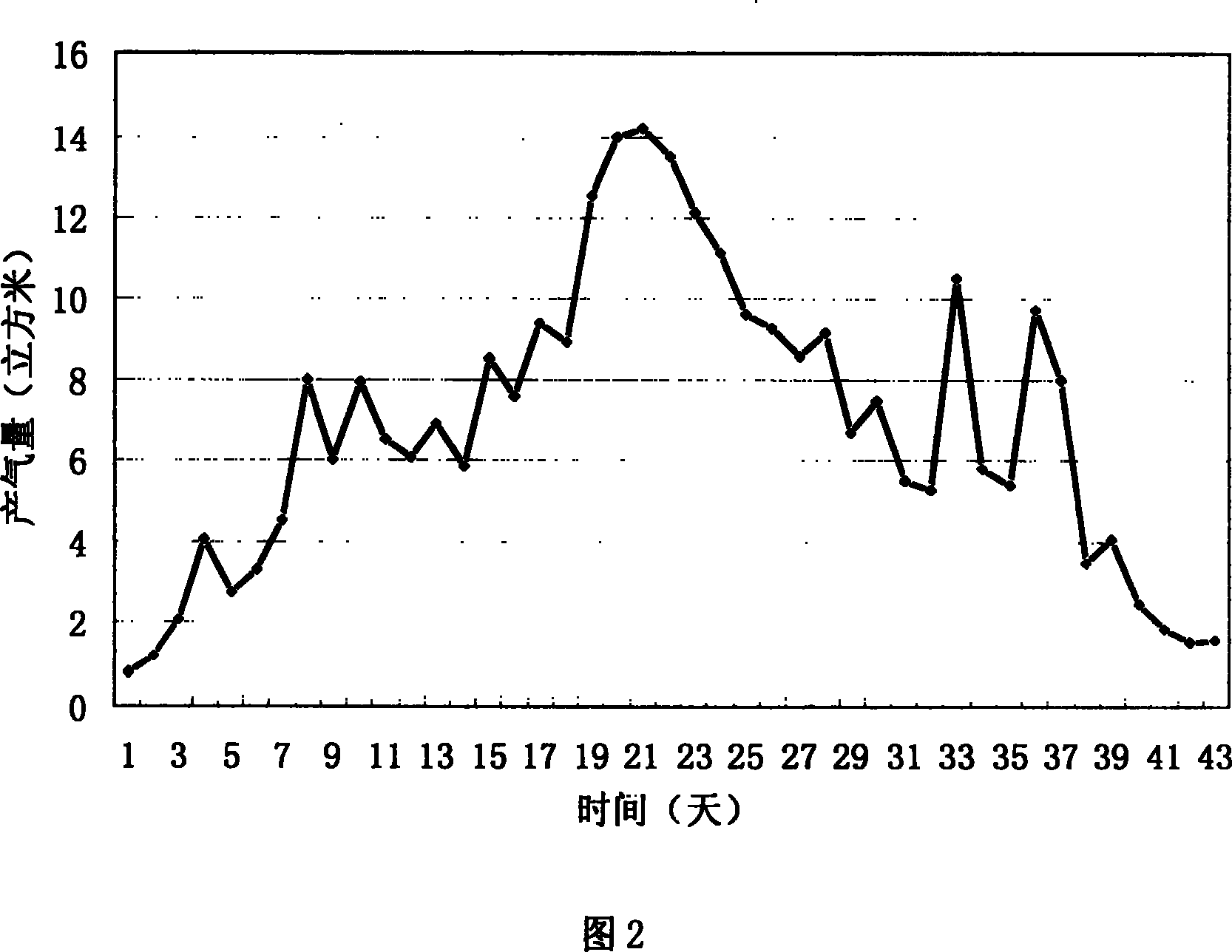

[0036] A small business produces biogas from Spartina alterniflora.

[0037](1) Pretreatment of the raw material Spartina alterniflora; cutting the harvested aboveground part of Spartina alterniflora into small sections of 2-3 cm by manual or mechanical means;

[0038] (2) Add 30 kg of ammonium bicarbonate containing N element material in the Spartina alterniflora 1250kg of step (1) gained, mix, adjust the carbon-nitrogen ratio of mixture; Make the C / N of mixture be 30: 1;

[0039] (3) putting the mixture obtained in step (2) into a single-phase internal circulation fermentation device with a volume of 20 cubic meters, and adding 5 cubic meters of inoculum biogas slurry for inoculation to obtain fermentation raw materials;

[0040] (4) adding water to the fermentation raw material in step (3), until the water surface is higher than the fermentation raw material 20cm;

[0041] (5) Close the fermentation device, the gas outlet of the fermentation device is connected to the gas ...

Embodiment 3

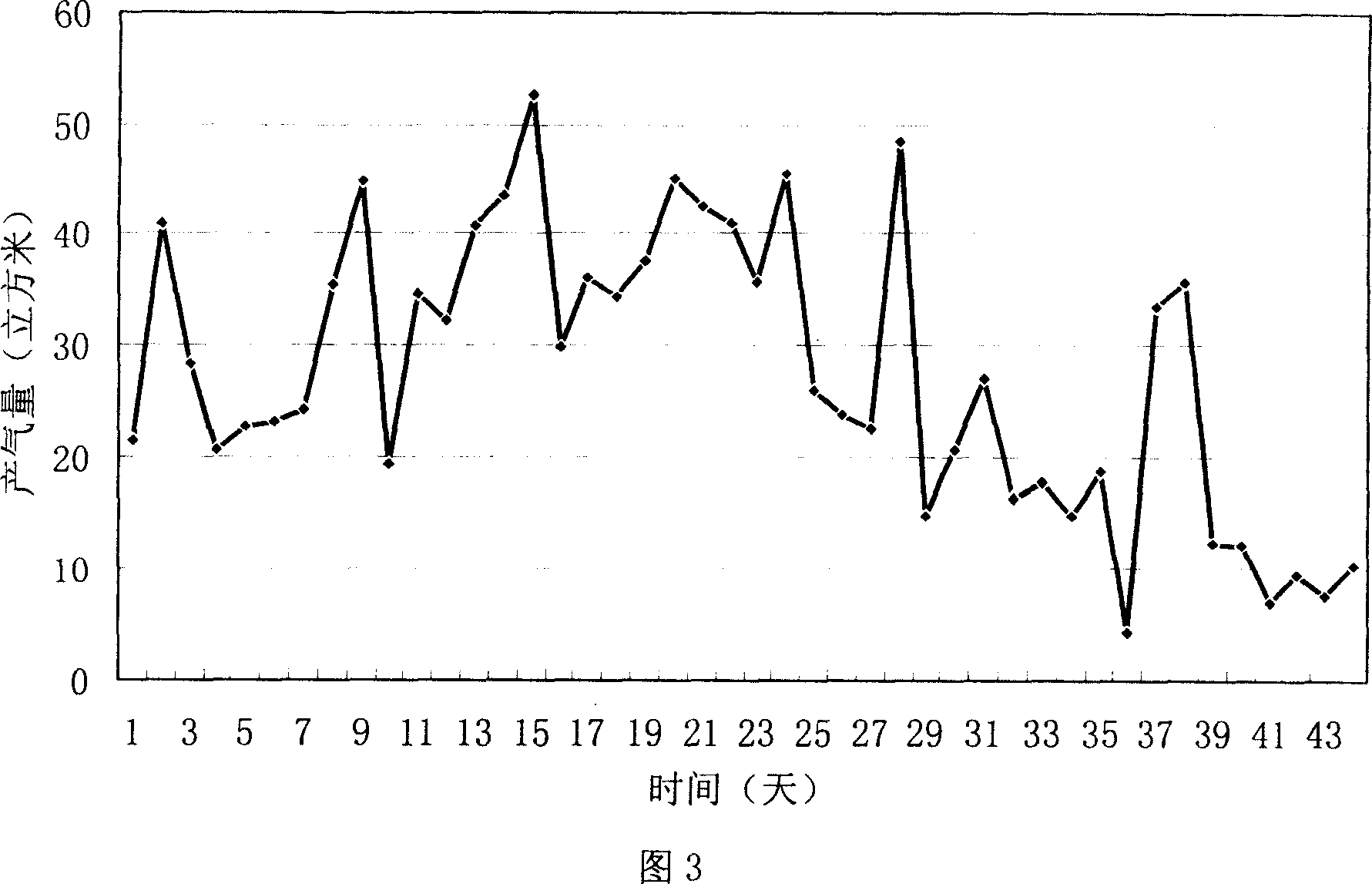

[0044] A medium-sized enterprise uses Spartina alterniflora to produce biogas.

[0045] (1) Pretreatment of the raw material Spartina alterniflora: cutting the harvested aboveground part of Spartina alterniflora into small sections of 2-3 cm by manual or mechanical means;

[0046] (2) Solid raw material management fermentation device: Add 6250 kg of pretreated Spartina alterniflora raw material to a 100 cubic meter solid raw material management fermentation device, add 125 kg of urea to make the carbon-nitrogen ratio in the mixture reach 25:1;

[0047] (3) Liquid microbial management reaction device: put polyethylene spherical packing with a volume of 5 cubic meters into a liquid microbial management reaction device with a volume of 20 cubic meters, add 2500 kg of anaerobic digested sludge with an inoculum water content of 80%, and add A certain amount of water, leaving a 20cm space on the upper part of the reactor;

[0048] (4) Close the fermentation device, the gas outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com