Alpha-sialon composite ceramic material and preparation method thereof

A technology of composite ceramics and ceramic materials, which is applied in the field of ceramic materials and their preparation processes, can solve problems such as high-temperature performance degradation, and achieve the effect of simple preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

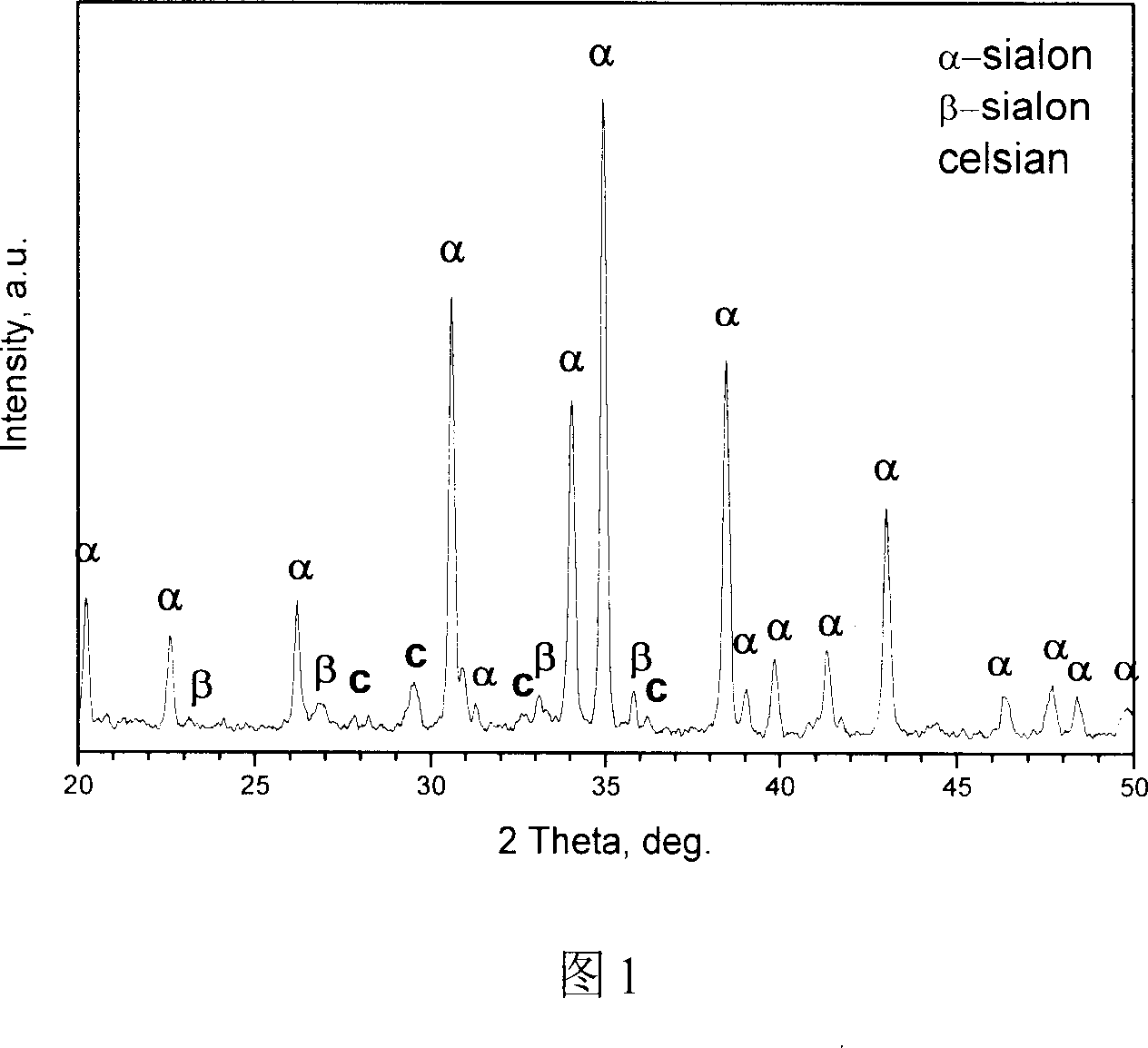

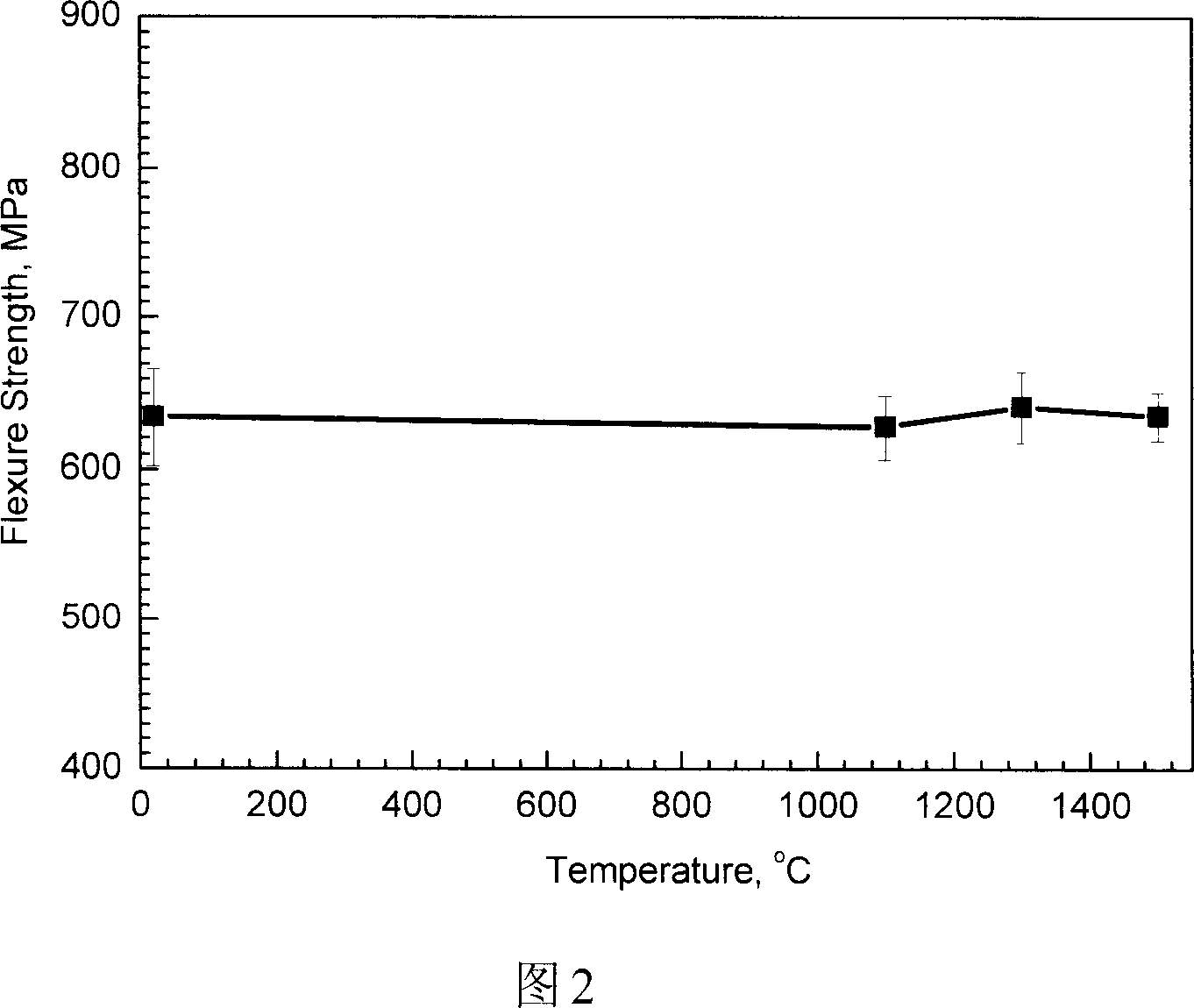

[0016] Specific embodiments: the α-sialon composite ceramic material of this embodiment adopts BAS as an additive to generate a self-toughening α-sialon material, and the weight percentage of BAS is 0.1% to 30%, and the optimum value is 5% to 10%.

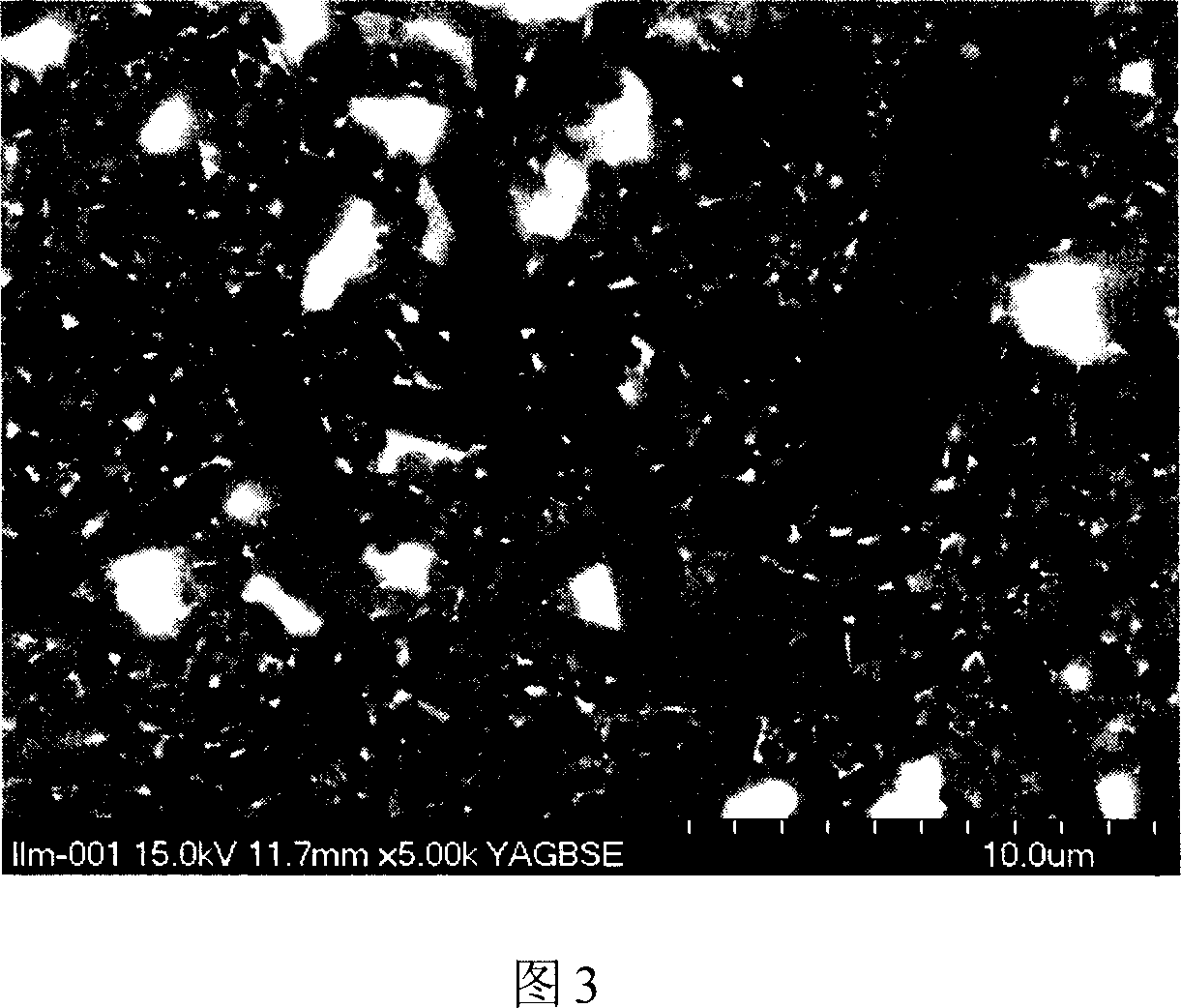

[0017] Barium feldspar can be used as an additive, BAS amorphous powder synthesized by solution chemical method [Ye Feng Northwestern Polytechnical University Postdoctoral Research Work Report, May 1997], its particle size is about 0.1 μm ~ 50 μm, preferably less than 5 μm; with BaCO 3 (or BaSO 4 ), Al2O 3 , SiO 2 The powders react in situ during the sintering process to generate BAS, and the purity of each powder is preferably greater than 99.5%, and the particle size is less than 5 μm. A small amount of Al can also be added to the BAS additive 2 o 3 , and the excess SiO in the system 2 The reaction produces mullite, which can improve the high temperature strength of the material. These Al 2 o 3 The mole percentage of BAS ...

specific Embodiment approach 2

[0020] Embodiment 2: In this embodiment, the α-sialon composite ceramic material described in Embodiment 1 is prepared according to the following steps: a. Mix the raw material powders uniformly according to the above ratio, and the mixing time is 2 to 36 hours; b. The uniform powder is cold-pressed at room temperature first, and then hot-pressed and sintered, or directly hot-pressed and sintered without cold-pressing. The sintering temperature is 1600°C-2000°C, the pressurization method is one-way or two-way pressurization, the applied pressure is 10-45MPa, and the sintering holding time is 0.5-2 hours. The sintering atmosphere is nitrogen or vacuum.

[0021] This embodiment can adopt following several mixing processes:

[0022] (1) Mix the powders evenly, the mixing method is wet mixing, and the mixing medium can be ethanol, isopropanol, etc. Ceramic balls (alumina balls or silicon nitride balls, etc.) can be added to improve mixing efficiency. The mixed powder and the mi...

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 2 in that the homogeneously mixed powder is sequentially subjected to cold pressing and pressureless sintering. The sintering temperature is 1600°C-2000°C, and the sintering holding time is 0.5-2 hours. The sintering atmosphere is nitrogen or vacuum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com