Nitrogen-doped titanium dioxide solvent thermal preparation method

A titanium dioxide, solvothermal technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effect of particle reduction, reduction of catalytic activity, and particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

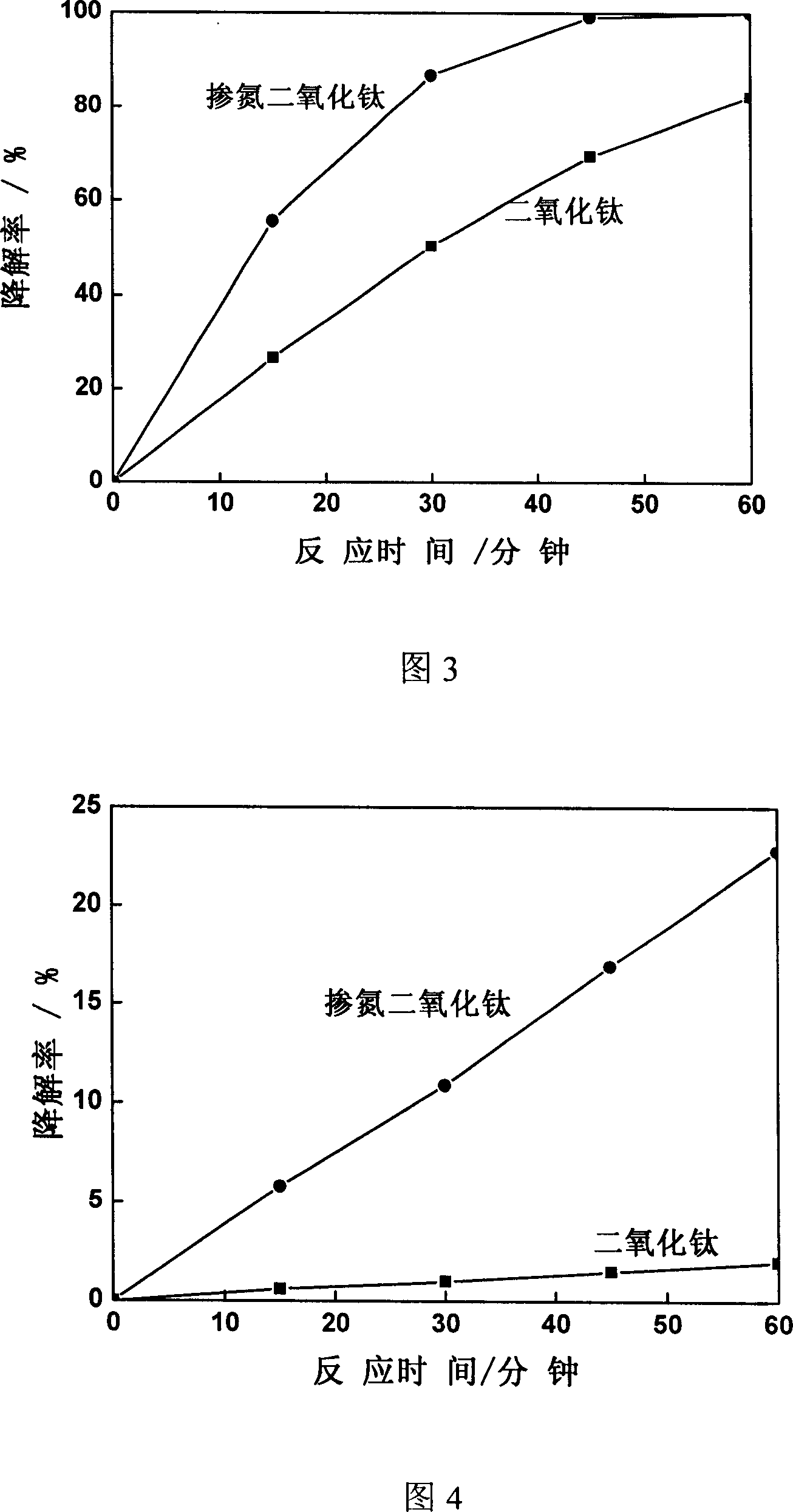

[0023]Add 1.0 g of titanium dioxide to the flask, add 20 g of triethanolamine, and then add 20 g of distilled water, that is, the weight ratio of titanium dioxide: nitrogen-containing organic matter (triethanolamine): solvent (water) is 1:20:20, and ultrasonically vibrate for 0.5 h. Pour the above mixture into a corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the temperature to 180°C, and reflux for 12 hours. The suspension was filtered, the solid was washed with distilled water and ethanol, and finally dried at 80° C. for 24 hours to obtain the nitrogen-doped titanium dioxide of the present invention. The nitrogen-doped titanium dioxide of the present invention has a nitrogen-doped mass of 8%, and the nitrogen-doped titanium dioxide of the present invention has high photocatalytic activity in evaluating the catalytic degradation of methyl orange under sunlight, and the degradation rate reaches 85% within 30 minutes.

preparation Embodiment 2

[0025] Add 1.0 g of titanium dioxide to the flask, add 10 g of triethanolamine, and then add 40 g of ethanol, that is, the weight ratio of titanium dioxide: nitrogen-containing organic matter (triethanolamine): solvent (ethanol) is 1:10:40, and ultrasonically vibrate for 1 h. Pour the above mixture into a corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the temperature to 140°C, and reflux for 36h. The suspension was filtered, the solid was washed with distilled water and ethanol, and finally dried at 120° C. for 12 hours to obtain the nitrogen-doped titanium dioxide of the present invention. The nitrogen-doped titanium dioxide of the present invention has a nitrogen-doped mass of 5%, and the nitrogen-doped titanium dioxide of the present invention has high photocatalytic activity in evaluating the catalytic degradation of methyl orange under sunlight, and the degradation rate reaches more than 90% within 30 minutes.

preparation Embodiment 3

[0027] Add 1.0 g of titanium dioxide to the flask, add 50 g of triethylamine, and then add 10 g of water, that is, the weight ratio of titanium dioxide: nitrogen-containing organic matter (triethylamine): solvent (water) is 1:50:10, and ultrasonically vibrate for 0.5 h. Pour the above mixture into a corrosion-resistant stainless steel hydrothermal reactor at room temperature, raise the temperature to 120°C, and reflux for 8 hours. The suspension is filtered, the solid is washed with distilled water and ethanol, and finally dried at 100° C. for 10 h to obtain the nitrogen-doped titanium dioxide of the present invention. The nitrogen-doped titanium dioxide of the present invention has a nitrogen-doped mass of 10%, and the nitrogen-doped titanium dioxide of the present invention has high photocatalytic activity in the catalytic degradation evaluation of methyl orange under sunlight, and the degradation rate reaches more than 90% within 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com