Method for improving milk lactoprotein content by use of processing protein feedstuff

A technology of protein feed and content, which is applied in the field of animal nutrition and feed science of animal husbandry, can solve the problems of reducing the rumen pass rate of high-quality protein feed, cannot be popularized and used, and the effect is not ideal, so as to improve the three-dimensional pollution, increase the utilization rate, The effect of improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Example 1 Protection protein feed method screening example

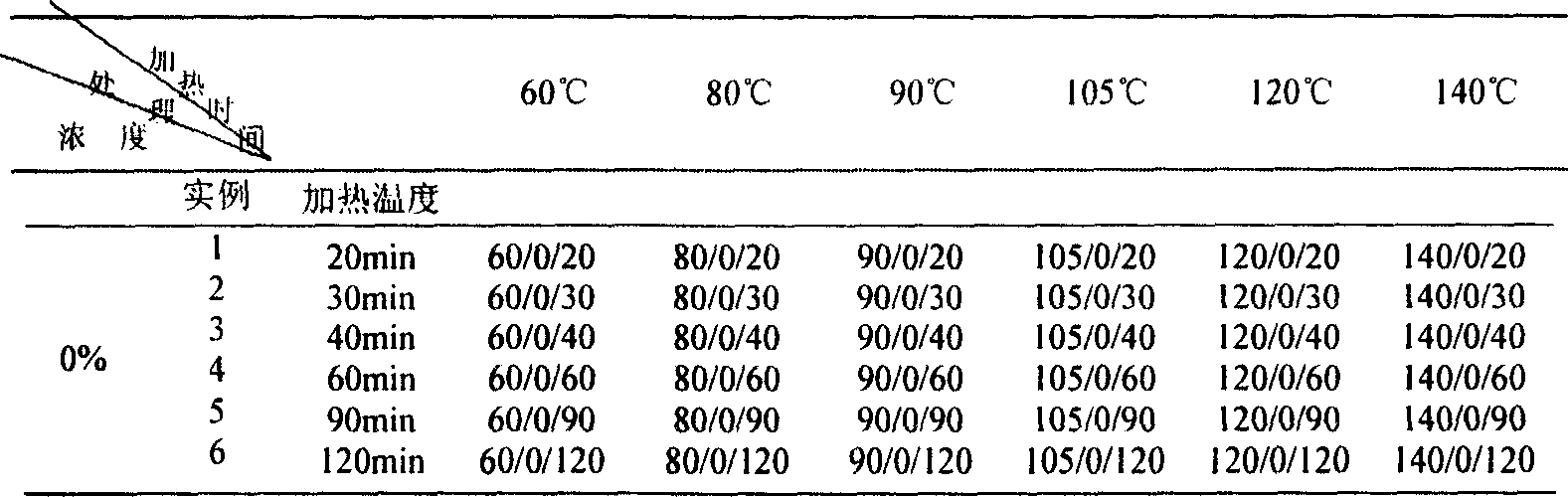

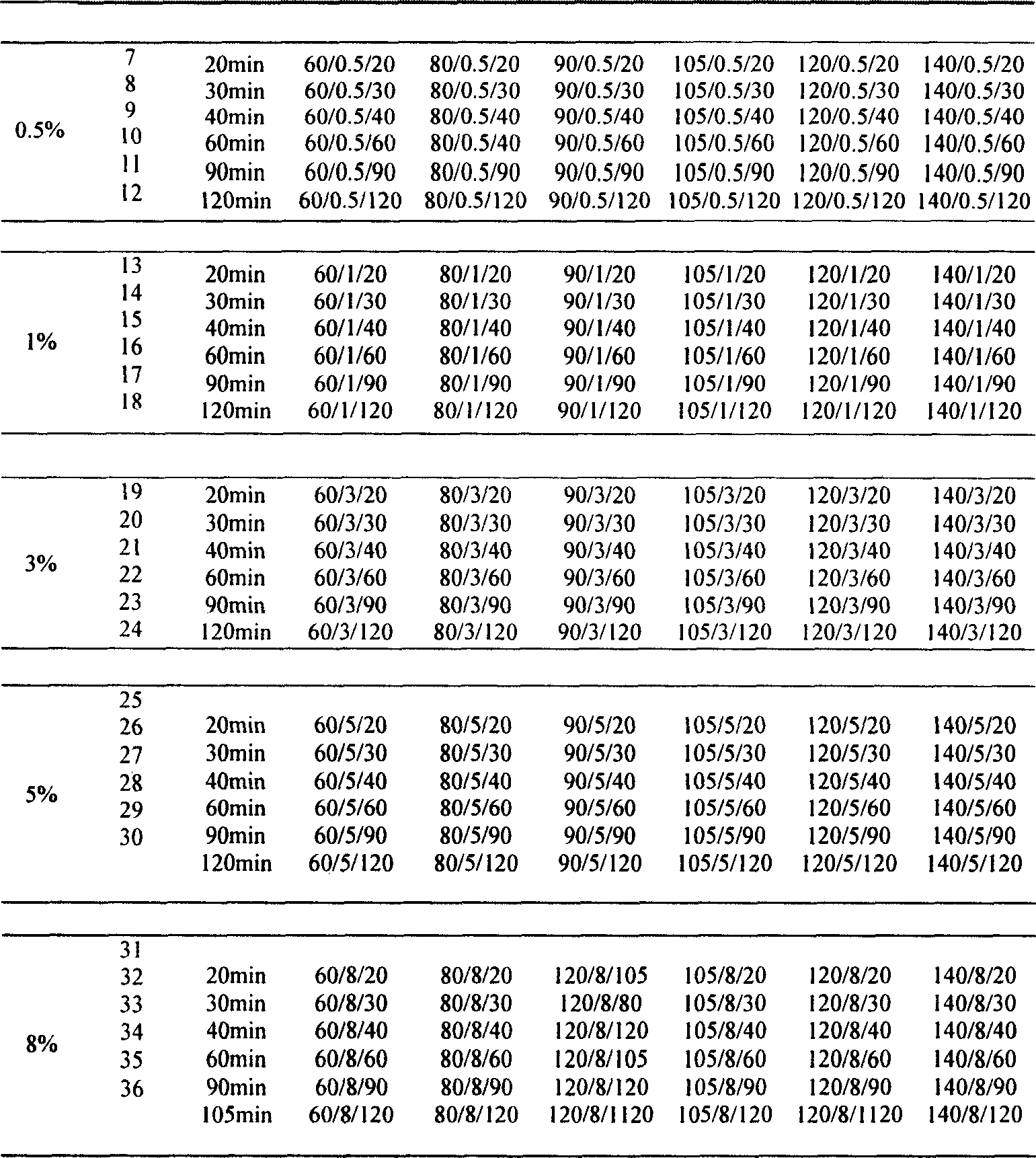

[0038] The rumen protein feed protection method is to spray 0.5%-8% polyhydroxy ketone (or aldehyde) (xylose) solution in the raw material (adopting soybean meal in this example), after fully mixing, in a certain 60 Heating at ℃-140 ℃ for 20-120 minutes to obtain rumen-passing protection protein feed with different treatments. Table 1 is a brief list of partial processing completed by the group of the present invention under laboratory conditions.

[0039] Table 1: Brief list of different treatment groups produced by composite processing technology

[0040] Note: The above treatment groups are expressed in the form of "number / number / number". For example: the combination 105 / 8 / 120 is the treatment group that added 8% xylose and heated for 120min at 105°C. It is still expressed in this way in the following examples.

[0041] The parameters of D-xylose addition 3%, temperature 90° C., and time 90 min in E...

example 2

[0042] Example 2 adopts single pepsin enzymolysis method to measure the crude protein degradation rate of processing soybean meal

[0043] Weigh 0.5g of the protected soybean meal obtained in Example 1 and put it into a 100ml Erlenmeyer flask, add 30ml of an enzyme solution containing 120IU pepsin and a pH of 1.55, and incubate on a water-bath shaker at 40°C and 90rpt / min for 24h. After taking it out, add 5ml of 20% SAA (sulfosalicylic acid) to each Erlenmeyer flask to precipitate undigested protein. After standing for 30 minutes, filter with medium-speed filter paper, and then wash the residue with preheated 1% SAA. . Transfer the residue together with the filter paper into a weighing bottle, and bake in an oven at 60°C for 24 hours to constant weight. Then use the Kjeldahl method to measure the protein content and calculate its dry matter disappearance rate and protein degradation rate, see Table 2.

[0044] Table 2 The protein degradation rate of soybean meal after treatm...

example 3

[0046] Example 3 adopts pepsin-trypsin two-step enzymolysis method to measure the crude protein degradation rate of processing soybean meal

[0047] Weigh about 0.5g of the protected soybean meal obtained in Example 1 and put it into a 100ml Erlenmeyer flask, add 30ml of an enzyme solution containing 120IU pepsin and a pH of 1.55, and cultivate it in a water bath for 6 hours at 40°C and 90rpt / min. Adjust the pH of the digestive solution to 7.8, add 5 ml of an enzyme solution with a pH of 7.8 containing 160 mg of trypsin, and continue culturing at 39° C. for 18 hours. After taking it out, add 5ml of 20% SAA (sulfosalicylic acid) to each conical flask to precipitate the undigested protein. After standing for 30 minutes, filter it with medium-speed filter paper, and then use preheated 1% SAA to filter the residue. rinse. Transfer the residue together with the filter paper into a weighing bottle, and bake in an oven at 60°C for 24 hours to constant weight. Then the Kjeldahl meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com