Process for preparing argatroban intermediates

A technology for argatroban and intermediates, which is applied in the field of preparing argatroban intermediates, can solve the problems of unsuitability for industrial production, many reaction by-products, and difficult separation, and achieve complete reaction, simple operation, and easy purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

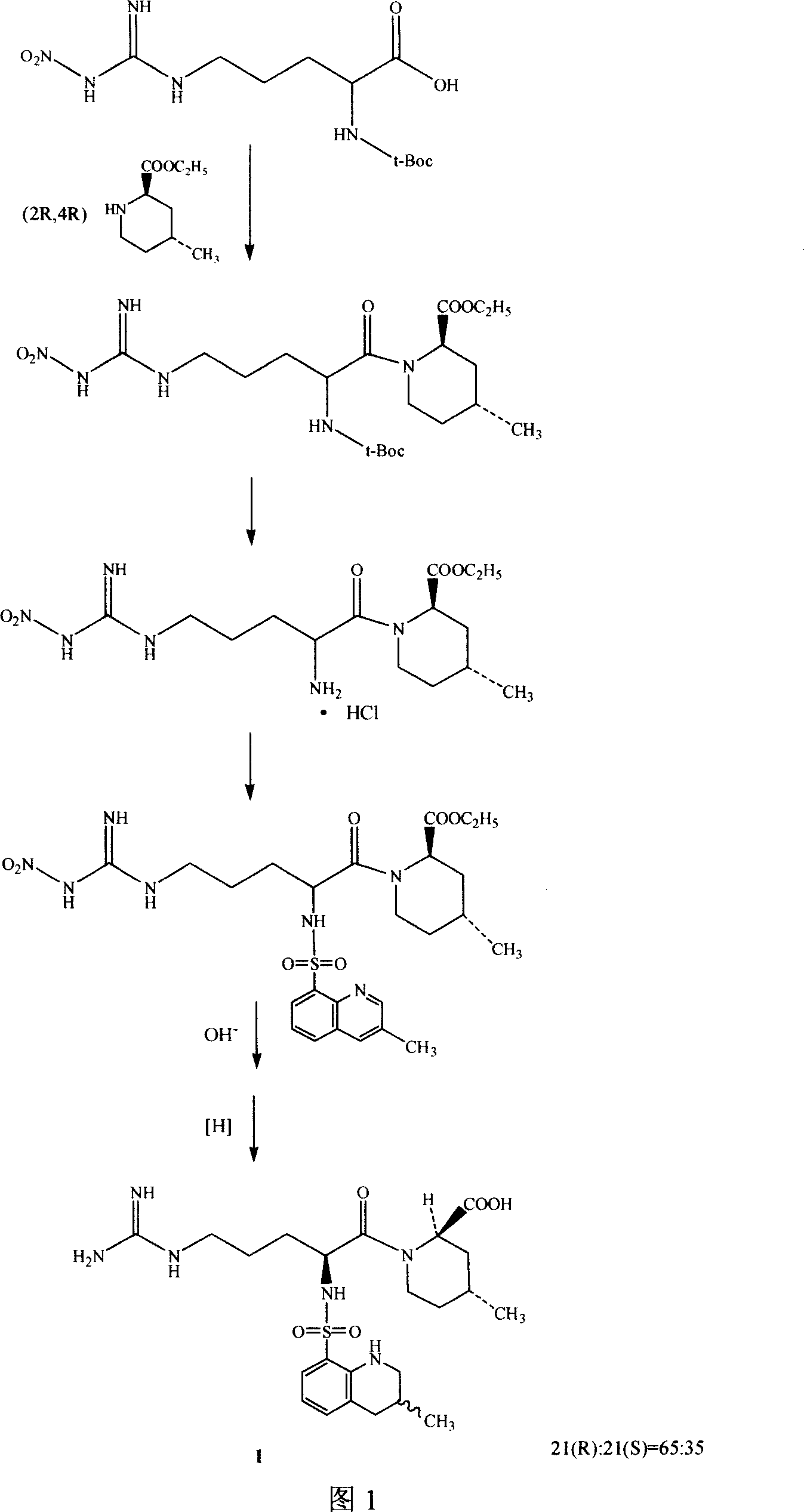

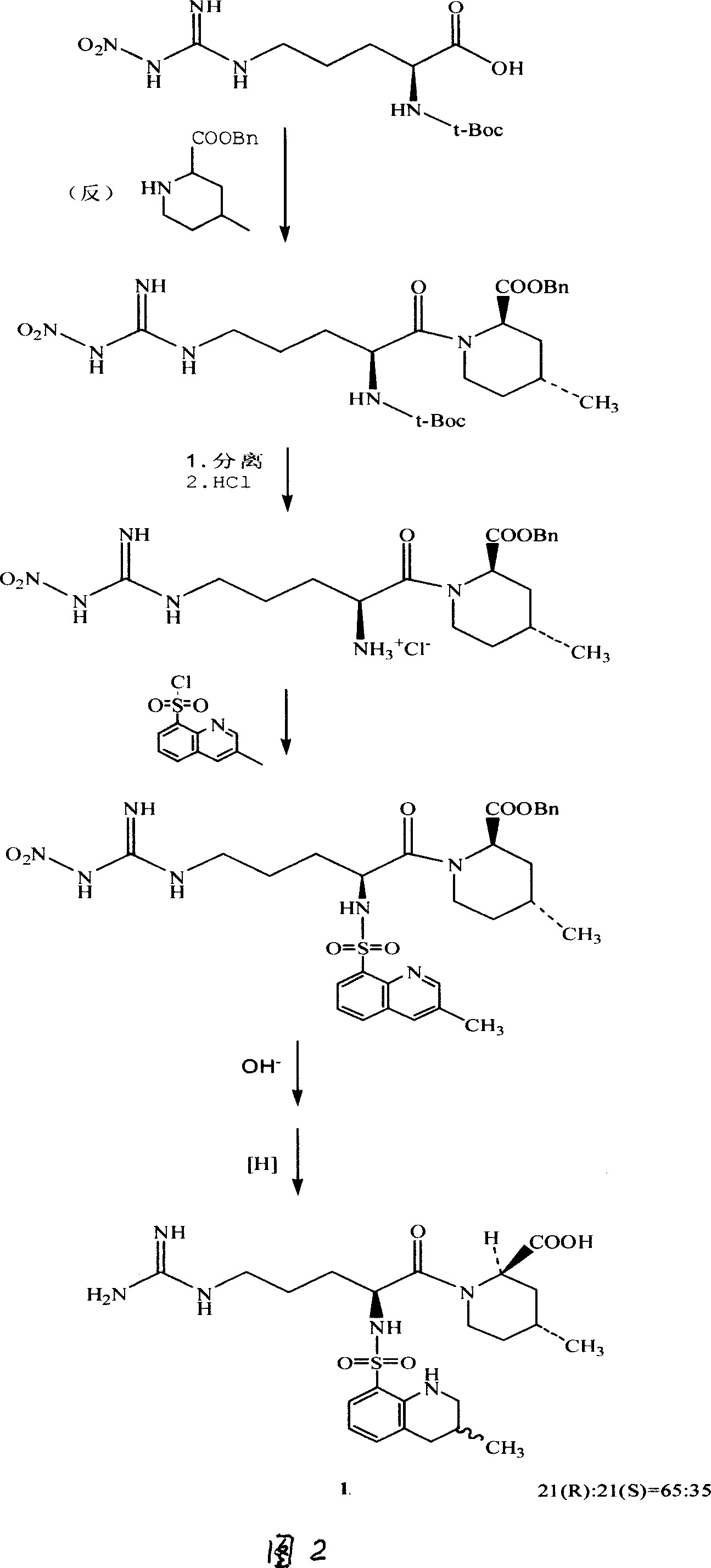

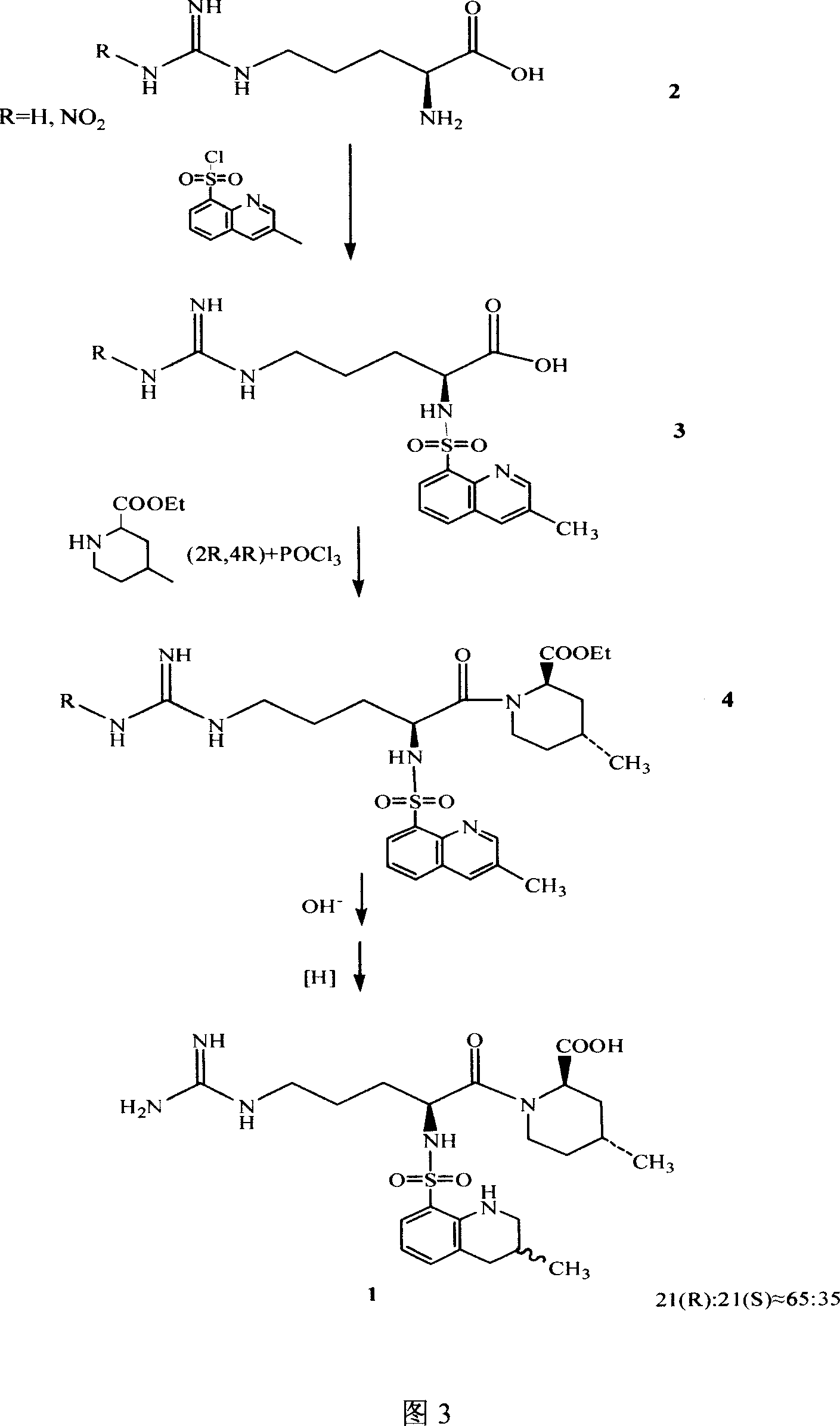

Method used

Image

Examples

Embodiment 1

[0028] Example 1.N G - Preparation of nitro-L-arginine

[0029] Add 165 g of concentrated sulfuric acid into a 300 ml four-necked reaction flask, add 34.8 g (0.2 mol) of L-arginine with stirring, stir until transparent, add 20.0 g (0.4 mol) of ammonium nitrate, and stir at room temperature for 3 hours. After the reaction, the reaction solution was poured into 600 grams of ice water, neutralized with about 370 grams of ammonia (17%), controlled to pH 6.5, and a white solid was precipitated, filtered, washed with water, and recrystallized with 900 grams of water to obtain N G - Nitro-L-arginine 35.7 grams, content 98.5% (HPLC quantitative analysis method), yield 80.3%.

Embodiment 2

[0030] Example 2.N G -Nitro-N 2 - Preparation of tBoc-L-arginine

[0031] Add 100ml of water into a 300ml four-necked reaction flask, add 4.4 grams (1.1mol) of sodium hydroxide under stirring, cool after stirring and dissolving, add 20.0 grams (0.091mol) of N G-Nitro-L-arginine and 52 grams of tert-butanol, stirred for a while to obtain a transparent solution, added 25.9 grams (0.119mol) of di-tert-butyl carbonate at a liquid temperature of G -Nitro-N 2 - tBoc-L-arginine (HPLC quantitative analysis method), content 96.5%, yield 57.8%.

Embodiment 3

[0032] Example 3. (2R, 4R)-1-[N G -Nitro-N 2 -(tert-butyloxycarbonyl)-L-arginine]-4

[0033] -Preparation of methyl-2-piperidinecarboxylic acid ethyl ester

[0034] Into a 5000ml four-necked reaction flask, add 3000ml of dichloromethane, under stirring, add 112.8g (0.655mol) of ethyl (2R,4R)-4-methyl-2-piperidinecarboxylate, and dissolve it in about 0.5 hours. Under stirring at room temperature, add DCC134.8 g (0.655 mol), continue stirring for 0.5 hours, add N G -Nitro-N 2 - 209.0 g (0.655 mol) of tBoc-L-arginine, stirred at room temperature for 2 hours, detected by TLC (solvent system is ethyl acetate), the raw materials basically disappeared, and the reaction ended. Add 600ml of water, stir for 0.5 hours, cool the reaction solution to 0°C, filter to remove the by-product urea, separate the filtrate, remove the water layer, wash the organic layer twice with 950ml of 10% sodium hydroxide solution, and wash with 600ml of 10% citric acid solution to neutrality, then washed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com