Hydrocracking method for producing chemical raw material

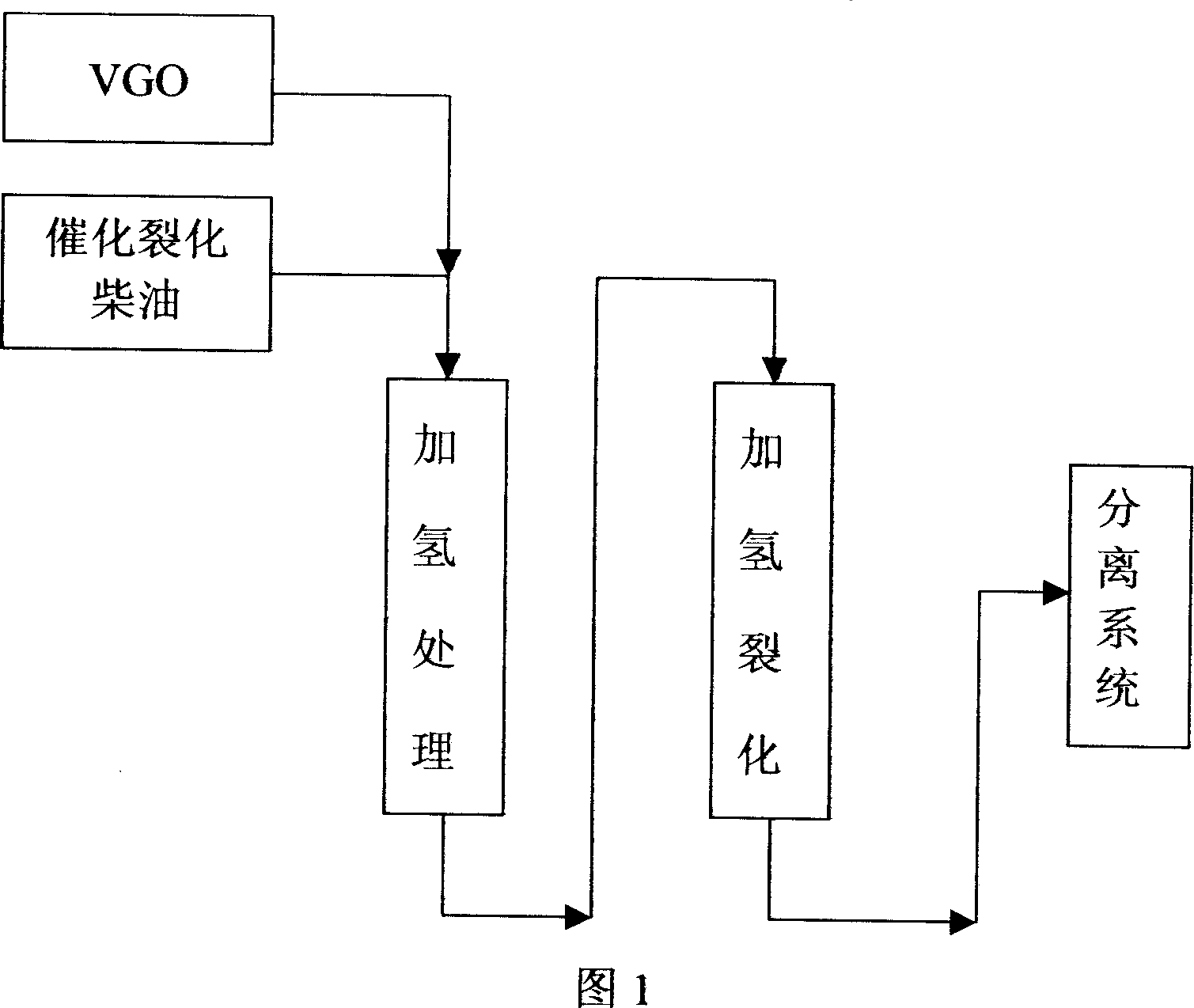

A technology for hydrocracking and chemical raw materials, which is applied in the fields of hydrocarbon oil cracking and petroleum industry. It can solve the problems of difficult effective treatment, uneconomical rationality, and large hydrogen consumption, and achieves the increase of aromatics latent content and aromatics latent content. Effects of high and low BMCI values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The second preparation method of the hydrocracking catalyst recommended by the present invention is as follows: the Y-type molecular sieve precursor is mixed with the binder obtained by the peptization of small-pore alumina and dilute nitric acid solution, extruded, and formed, wherein the mixing process Selectively add macroporous alumina and / or amorphous silica-alumina; treat the above molded product at high temperature with water vapor or ammonia-water vapor, the treatment conditions are as follows: temperature 400-700°C, preferably 500-600°C, pressure 0-600°C 0.2MPa, where the partial pressure of ammonia is 0-0.05MPa, and the treatment time is 0.5-3.0 hours to obtain a carrier; the catalyst carrier is impregnated with a solution containing active metal, dried and roasted to prepare the hydrocracking catalyst of the present invention. Wherein, after the mixture containing the Y-type molecular sieve precursor is treated with water vapor or ammonia gas-high temperature,...

preparation Embodiment 1

[0041] The present embodiment prepares hydrocracking catalyst I, and concrete steps are as follows:

[0042] (1) The Y-type molecular sieve precursor A1 is subjected to hydrothermal treatment, wherein the hydrothermal treatment conditions are as follows: the temperature is 600° C., the water pressure is 0.1 MPa, and the treatment time is 1 hour to obtain the Y-type molecular sieve I;

[0043] (2) get the Y type molecular sieve I of 153.5 gram step (1) gained, by 120 gram small hole alumina (pore volume 0.47ml / g, specific surface area is 280m 2 / g), 0.2N dilute nitric acid solution 440ml peptized binder mixes, after extruding, molding, then through 110 ℃ of drying 5 hours, 600 ℃ of roasting 6 hours obtain catalyst carrier;

[0044](3) impregnating the catalyst carrier obtained in step (2) with an aqueous solution containing molybdenum and nickel, drying at 110° C. for 5 hours, and calcining at 500° C. for 5 hours to prepare the hydrocracking catalyst I of the present invention....

preparation Embodiment 2

[0046] This embodiment prepares hydrocracking catalyst II, and concrete steps are as follows:

[0047] (1) 170g Y-type molecular sieve precursor A1 is mixed with the adhesive (same as implementation 2) prepared by peptizing 80g of small-pore alumina and dilute nitric acid solution, extruded and formed;

[0048] (2) Use ammonia-water vapor to treat the molded product obtained in step (1) at high temperature, the treatment conditions are as follows: temperature 550°C, pressure 0.1MPa, ammonia partial pressure 0.01MPa, treatment time 1 hour, obtained Carrier, which contains Y-type molecular sieve II;

[0049] (3) impregnating the catalyst carrier obtained in step (2) with an aqueous solution containing tungsten and nickel, drying at 110° C. for 5 hours, and calcining at 500° C. for 5 hours to prepare the hydrocracking catalyst II of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com