Method for electrolyzing organic waste water using iridium tantalum stannum oxide coating titanium electrode

A tin oxide, electrolytic treatment technology, applied in the field of electrochemistry and environmental chemistry, can solve problems such as electrode life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

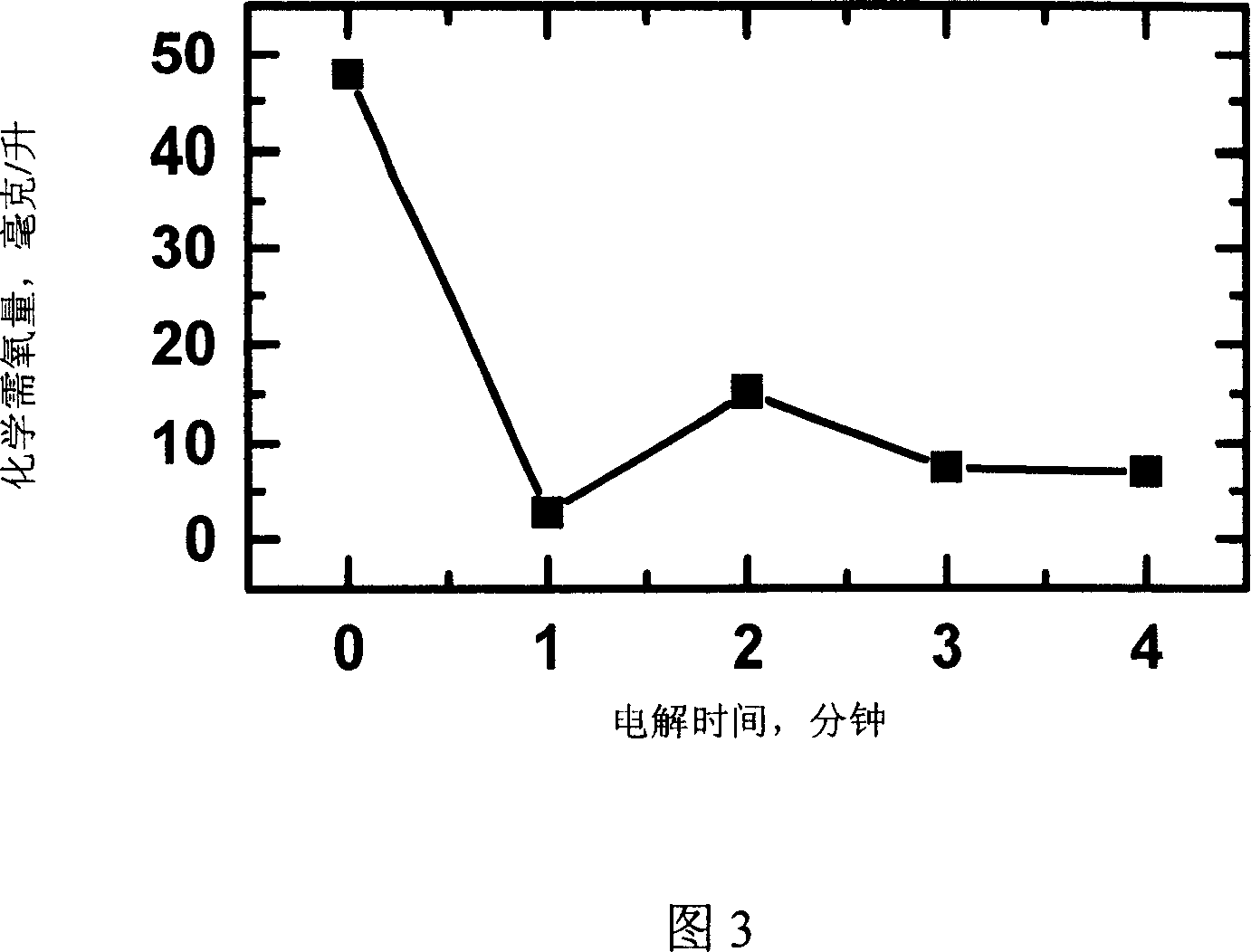

[0019] Example 1 Direct current electrolytic treatment of actual oil refinery wastewater. The initial COD value is 90mg / L. Using electrodes as SnO 2 / IrO 2 -Ta 2 o 5 / Ti, NaCl concentration 5%, current density 1600A m -2 , anode area 5cm -2 , The distance between the plates is 0.5cm. After 10 minutes of electrolysis, the removal rate of COD value reached 92.8%. From 10 to 45 minutes, the COD remained basically unchanged. The relationship between processing time and COD is shown in Figure 2.

Embodiment 2

[0020] Example 2 Direct current electrolytic treatment of actual ethylene production wastewater. The initial COD value is 50mg / L. The electrode used is SnO 2 -IrO 2 -Ta 2 o 5 / Ti, NaCl concentration 0.1%, current density 1600A m -2 , anode area 5cm -2 , plate spacing 1cm. The concentration of NaCl added is very low, and after 1 minute of electrolysis, the removal rate of COD value reaches 90.8%. The water quality standard complies with the requirements for boiler circulating water. Calculate the electric energy consumed by the electrolysis of 1 ton of this ethylene waste water to be 2.0 degrees. The relationship between processing time and COD is shown in Figure 3.

Embodiment 3

[0021] Example 3 Pulse electrolysis treatment of ethylene wastewater, comprehensive wastewater and ethylene synthesis hexanediol wastewater of a petrochemical company. Using electrodes as SnO 2 -IrO 2 -Ta 2 o 5 / Ti, anode area 4cm -2 , plate spacing 1cm. Using sawtooth wave, the peak current density is 2500Am -2 , The pulse period is 1ms, the on-off ratio is 1:1 and the additional DC component is 0. The test results show that the solid matter (SS) and turbidity of the organic wastewater before electrolysis have basically met the water reuse standard, but it is still difficult to completely remove the COD and chroma in the wastewater. Pulse current electrolysis is used to treat organic wastewater. After electrolysis, COD, chroma, and solid matter (SS) of organic wastewater can be effectively removed. Among them, the COD of organic wastewater can basically meet the standard of reclaimed water reuse (COD is lower than 20mg / L), especially the COD of comprehensive wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com