Comprehensive automatic control system for welding process of high-frequency welded pipe

An automatic control system and welding process technology, applied in the field of welded pipe welding, can solve the problems of fast response, lack of popularization and application, and high maintenance costs, and achieve the effects of improving control accuracy, improving welding quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

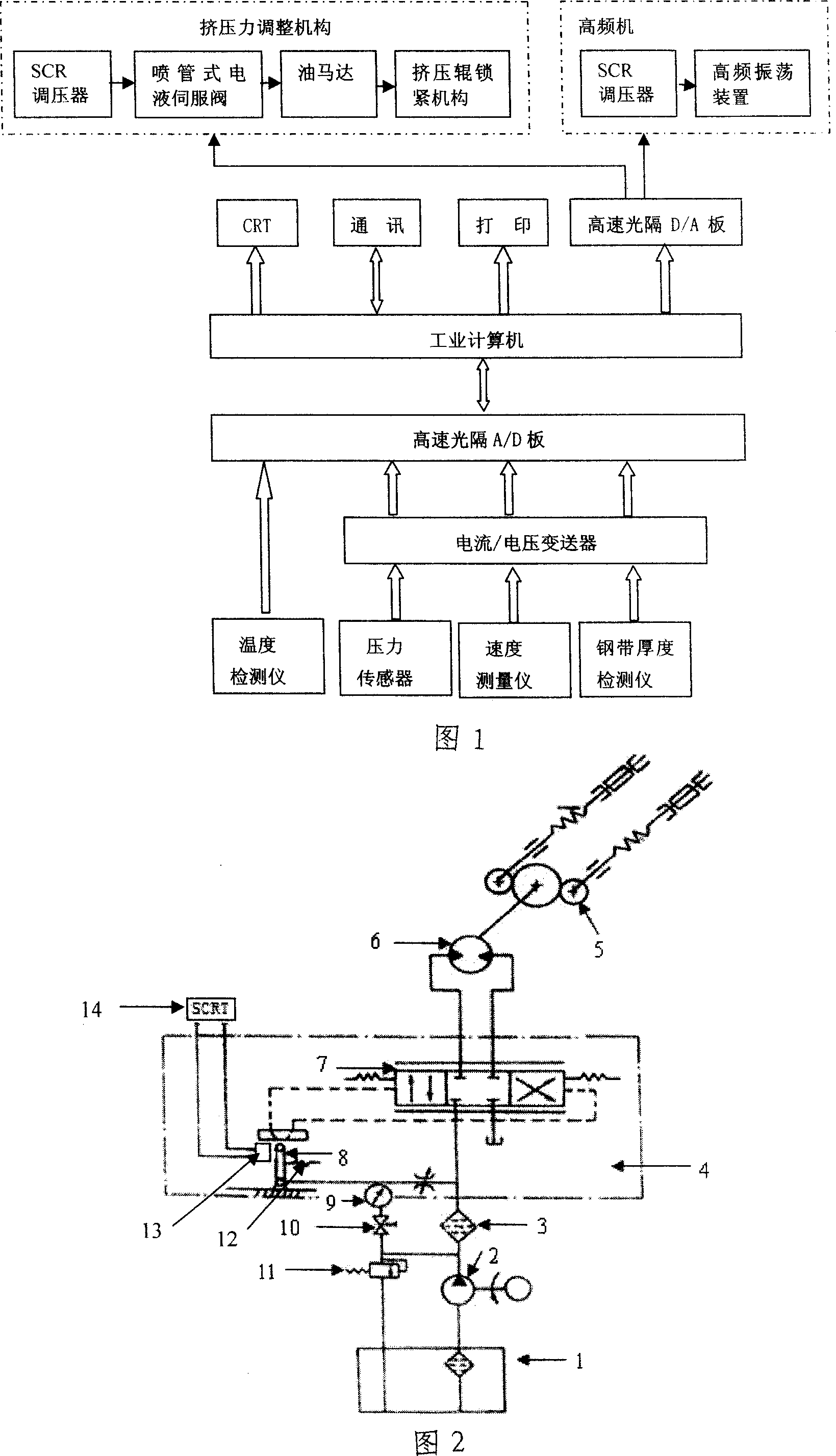

[0015] Embodiment 1 (referring to Fig. 1,3):

[0016] The control system of embodiment 1 includes a temperature detector for detecting welding temperature, a pressure sensor for detecting extrusion force, a speed measuring instrument for detecting welding speed, a steel strip thickness detector, a current / voltage transmitter, a high-speed optical isolation A / D board, industrial computer installed with fuzzy adaptive algorithm with hierarchical structure, high-speed optical isolation D / A board, high-frequency machine; the output terminal of the temperature detector is connected to the input end of the high-speed optical isolation A / D board, pressure sensor, The output ends of the speed measuring instrument and the steel strip thickness detector are respectively connected to the input end of the high-speed optical isolation A / D board through the current / voltage transmitter, and the high-speed optical isolation A / D board is connected with the industrial computer through the bus. ...

Embodiment 2

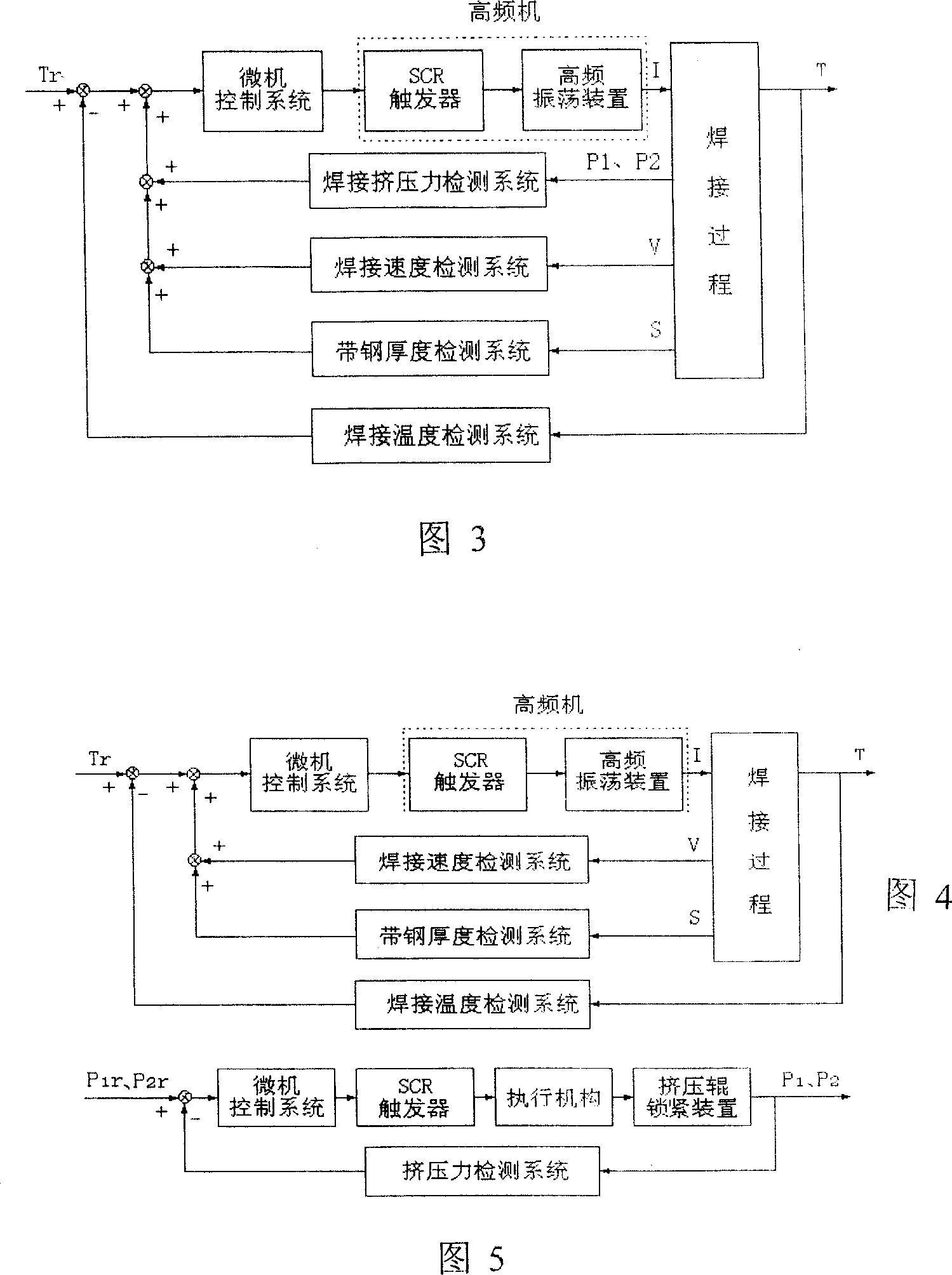

[0022] Embodiment 2 (referring to Fig. 1,2,4,5):

[0023] The difference between embodiment 2 and embodiment 1 is that the extrusion force adjustment mechanism (see Fig. 1, 2) is adopted, and the extrusion force adjustment mechanism is composed of SCR pressure regulator 14, nozzle type electro-hydraulic servo valve 4, oil motor 6, The squeeze roller locking mechanism is composed of the SCR regulator 14 output terminal connected to the coil of the electromagnet 13 located on the left side of the nozzle 8, the nozzle type electro-hydraulic servo valve 4 is connected with the oil motor 6 through the pipeline, and the oil motor 6 The output shaft is connected with the tension bolt through the gear set 5.

[0024] The control principle of Embodiment 2 is shown in Figures 4 and 5, which is a comprehensive automatic control scheme for the extrusion force independent closed-loop welding process (see Figures 4 and 5):

[0025] (1) The welding temperature T is automatically controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com