Degradable polymer supported nanometer Daunorubicin microsphere and its prepn process

A technology for carrying daunorubicin and degrading polymers, applied in the field of biomedical materials, can solve problems such as damage to normal cells, adverse reactions, and problems in the thoroughness of surgery, and achieve good therapeutic effect, good stability, and avoid magnetic distribution. uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

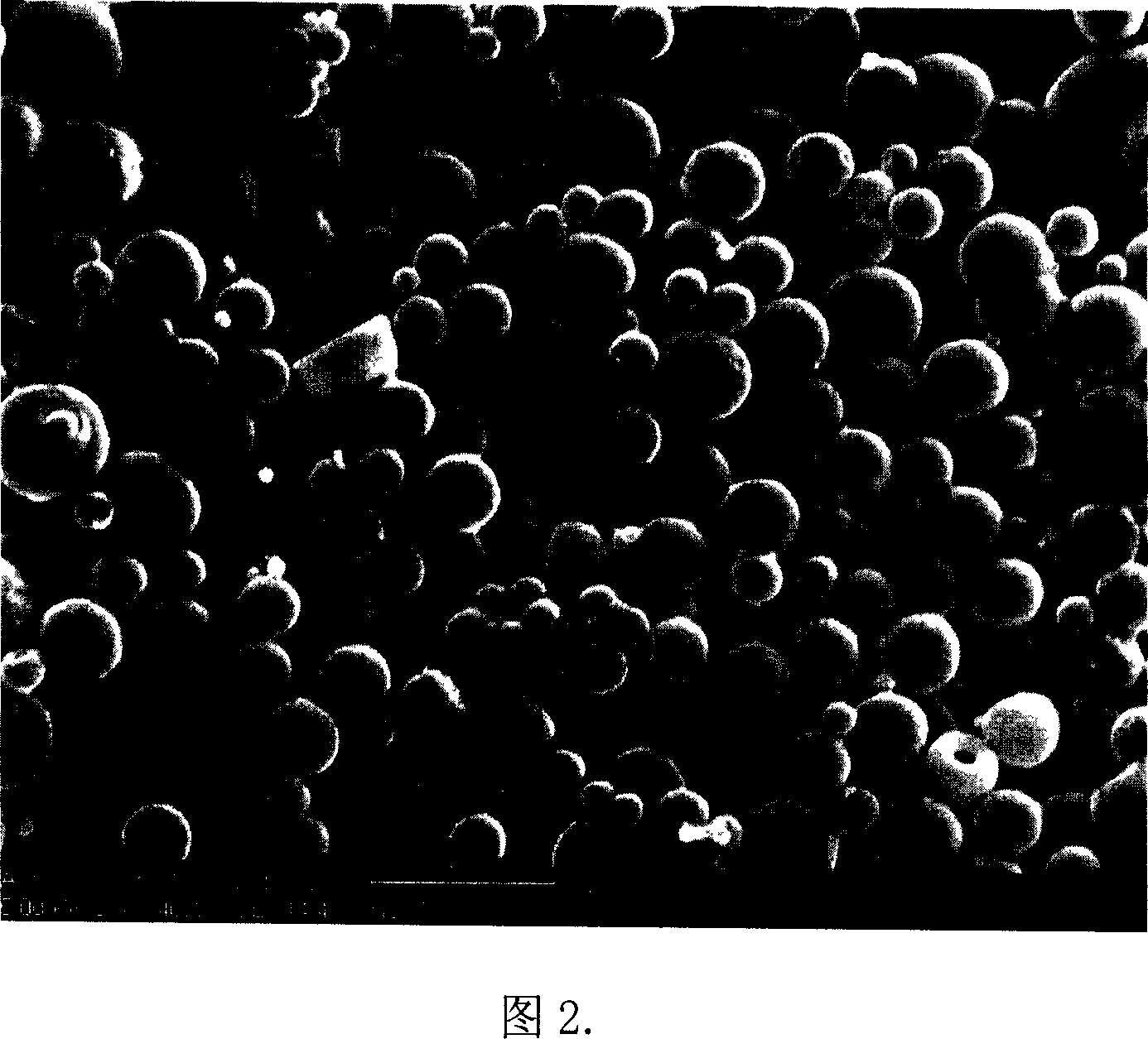

Embodiment 1

[0020] The polylactic acid is dissolved in an organic solvent with a volume ratio of methylene chloride: acetone=3: 1 to form an organic solution with a concentration of 5 mg / ml, and then with an aqueous solution containing daunorubicin 2.5 mg / ml by volume is 5 mg / ml. : 1 mixed, emulsified into a primary emulsion by ultrasonic, added this primary emulsion to 30 ml of a 1% gelatin aqueous solution, sonicated again to form a double emulsion, and slowly added the double emulsion to 150 ml of a 0.5% gelatin aqueous solution, Keep stirring at a high speed during dropwise addition, and maintain stirring for 1 hour after the end of dropping, to partially solidify the surface of the nano-microspheres, and then maintain stirring under negative pressure to accelerate the volatilization of the organic solvent in the emulsion system to completeness through the action of negative pressure. Finally, the solid nano-microspheres are collected by low-temperature high-speed centrifugation, washe...

Embodiment 2

[0023] The polylactic acid is dissolved in an organic solvent with a volume ratio of methylene chloride: acetone=4: 1 to form an organic solution with a concentration of 10 mg / ml, and then with an aqueous solution containing daunorubicin 5 mg / ml by volume to be 10 : 1 mixed, emulsified into a primary emulsion by ultrasonic, added this primary emulsion to 30 ml of a 1% gelatin aqueous solution, sonicated again to form a double emulsion, and slowly added the double emulsion to 150 ml of a 0.5% gelatin aqueous solution, Keep stirring at a high speed during dropwise addition, and maintain stirring for 2 hours after the dropwise addition, to partially solidify the surface of the nano-microspheres, and then maintain stirring under negative pressure to accelerate the volatilization of the organic solvent in the emulsion system to completeness through the action of negative pressure. Finally, the solid nano-microspheres are collected by low-temperature high-speed centrifugation, washed...

Embodiment 3

[0026] The polylactic acid is dissolved in an organic solvent with a volume ratio of methylene chloride: acetone=5: 1 to form an organic solution with a concentration of 20 mg / ml, and then with an aqueous solution containing daunorubicin 10 mg / ml by volume to be 20 : 1 mixed, emulsified into a primary emulsion by ultrasonic, added this primary emulsion to 30 ml of a 1% gelatin aqueous solution, sonicated again to form a double emulsion, and slowly added the double emulsion to 150 ml of a 0.5% gelatin aqueous solution, Keep stirring at a high speed during dropwise addition, and maintain stirring for 1.5 hours after the dropwise addition to partially solidify the surface of the nano-microspheres, and then maintain stirring under negative pressure to accelerate the volatilization of the organic solvent in the emulsion system to completeness through the action of negative pressure. Finally, the solid nano-microspheres are collected by low-temperature high-speed centrifugation, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com