Prepn process and application of metal-carbon nanometer composite material

A composite material, carbon nanotechnology, applied in chemical instruments and methods, catalyst activation/preparation, other chemical processes, etc., can solve problems such as weak reducibility, and achieve the effects of simple method, short preparation period and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

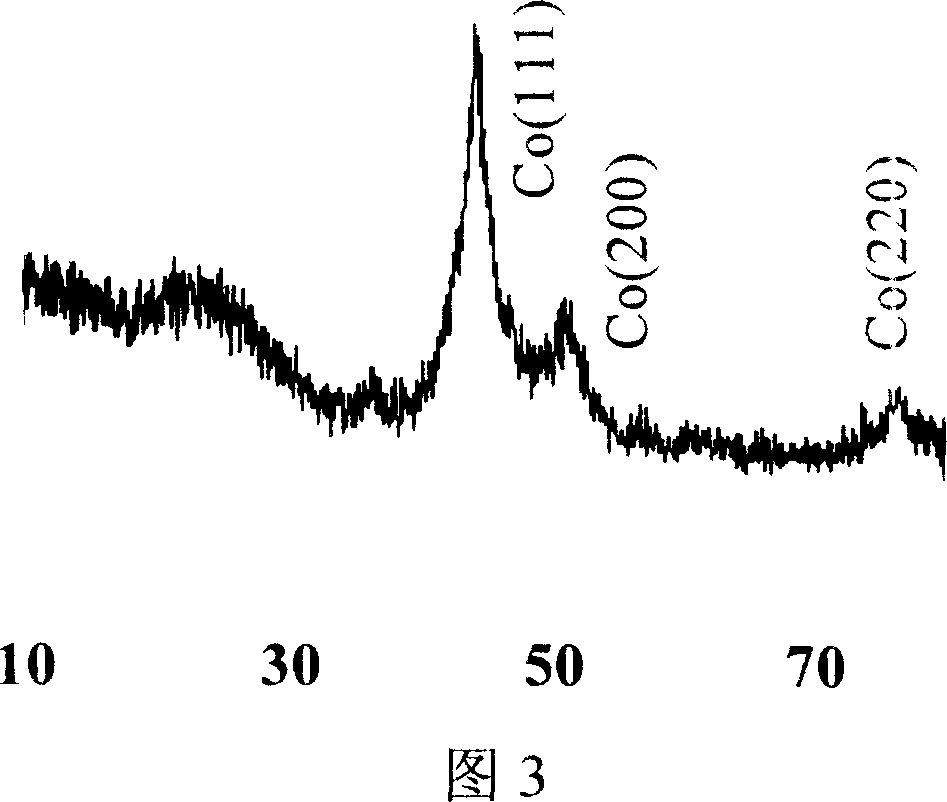

[0019] Weigh 0.3g Co(AC) 2 Add it into 30mL of deionized water, stir to dissolve, then pipette 0.5mL of furfural solution into it, stir evenly, place it in a 40mL stainless steel pressure-resistant reactor, react at 180°C for 15h, and filter, wash and dry the resulting precipitate. A brown powder was obtained. Observing the obtained sample microspheres with a scanning electron microscope, the size of the microspheres is 2-5 microns. The obtained powder was placed in a tubular heating furnace, heated to 700°C at a heating rate of 2°C / min in a high-purity nitrogen atmosphere, and kept for 3 hours to obtain a cobalt-carbon nanocomposite material, which was identified as metallic cobalt by X-ray powder. The specific surface area of the sample is 339m 2 / g. ICP results showed that the mass percent content of metallic cobalt was 6.1%.

Embodiment 2

[0021] Weigh 0.3g Co(AC) 2 Add it to 15mL deionized water and 15mL ethylene glycol mixed solution, stir to dissolve, then pipette 0.5mL furfural solution and add it, stir evenly, put it in a 40mL stainless steel pressure-resistant reactor, and react at 180°C for 15h, the obtained precipitate After filtering, washing and drying, a brown powder was obtained. The sample obtained by scanning electron microscopy is a microsphere composed of about 50nm sheets, the size of the microsphere is 3-7 microns, and the specific surface area is 26m 2 / g. The obtained powder is placed in a tubular heating furnace, heated to 700°C at a heating rate of 2°C / min in a high-purity nitrogen atmosphere, and kept for 3 hours to obtain a cobalt-carbon nanocomposite material, which is identified as metallic cobalt by X-ray powder. It is observed by scanning electron microscope and transmission electron microscope that its morphology maintains the morphology of the precursor, but its size becomes small...

Embodiment 3

[0023] Weigh 0.3g Co(AC) 2 Add it into 30mL ethylene glycol mixed solution, stir to dissolve, then pipette 0.5mL furfural solution and add it, stir evenly, put it in a 40mL stainless steel pressure-resistant reaction kettle, react at 180°C for 15h, and the obtained precipitate is filtered, washed, After drying, a brown powder was obtained. Obtained samples obtained by scanning electron microscopy are small balls with a diameter of about 500 nm, and the dispersibility of the small balls is not very good. The obtained powder was placed in a tubular heating furnace, heated to 700°C at a heating rate of 2°C / min under a high-purity nitrogen atmosphere, and kept for 3 hours to obtain a cobalt-carbon nanocomposite material, which was identified as metallic cobalt and A mixture of cobalt oxides, mainly metallic cobalt. The specific surface area of the sample is 309m 2 / g, the pore size distribution is 0.5nm. ICP results showed that the mass percentage of metallic cobalt was 11.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com