Styrene oligomer diphenyl ketone type photoprimer capable of initiating radiopolymerization and its prepn process

A technology of photoinitiator and benzophenone, which is applied in the field of radiation-initiating polymerization initiators, can solve the problems of limited popularization and application, high price, and limited application range, and achieve wide application prospects, broad absorption spectrum, compatible good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

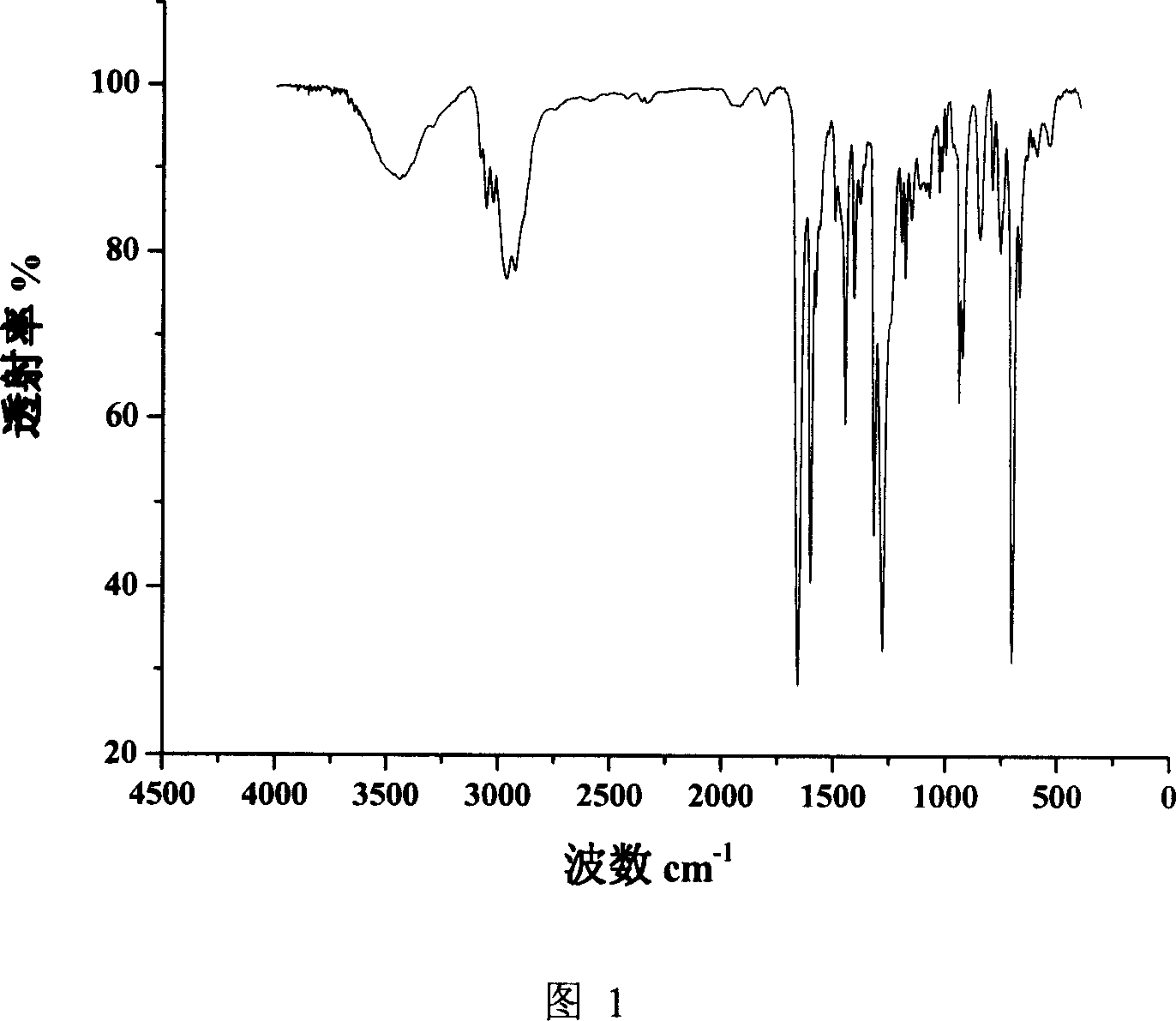

[0036] Embodiment 1, the preparation of benzoyl polystyrene linear oligomer

[0037] Add 720ml of dichloroethane to a 2L three-neck flask equipped with a stirrer, a separatory funnel with a calcium chloride drying tube, and a reflux condenser connected to an absorption gas device, and then add 40g of benzoyl peroxide while stirring and 200ml of styrene, heated to 80 ° C for about 4 hours to obtain a polystyrene oligomer solution. Cool down to room temperature, add 265 g of anhydrous aluminum trichloride in batches under stirring and raise the temperature to 40°C. Under vigorous stirring, 238 g (200 ml) of benzoyl chloride was added dropwise. After the reaction began to emit hydrogen chloride, the heating was stopped, and benzoyl chloride was added continuously for 4 hours. It was then refluxed for one hour, cooled to room temperature, slowly poured into 5 kg of crushed ice under stirring, and the upper oil layer was separated, washed successively with 5% sodium hydroxide sol...

Embodiment 2

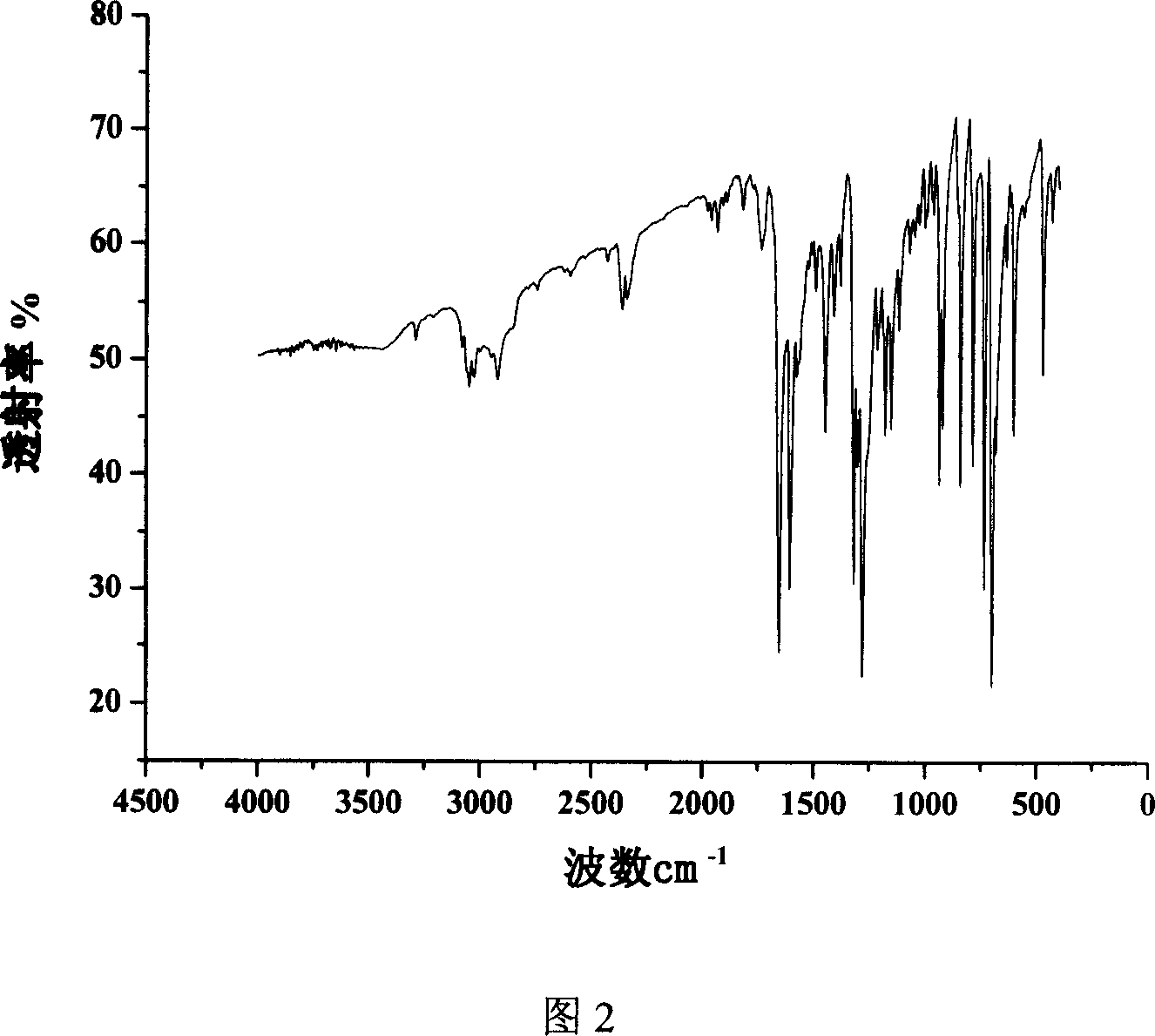

[0038] Embodiment 2,2,4, the preparation of 6-trimethylbenzoyl polystyrene linear oligomer

[0039] Add 720ml of dichloroethane to a 2L three-neck flask equipped with a stirrer, a separatory funnel with a calcium chloride drying tube, and a reflux condenser connected to an absorption gas device, and then add 40g of benzoyl peroxide while stirring and 200ml of styrene, heated to 80 ° C for about 4 hours to obtain a polystyrene oligomer solution. Cool down to room temperature, add 265 g of anhydrous aluminum trichloride in batches under stirring and raise the temperature to 40°C. Under vigorous stirring, 300 g of 2,4,6-trimethylbenzoyl chloride was added dropwise. After the reaction started to release hydrogen chloride, the heating was stopped, and 2,4,6-trimethylbenzoyl chloride was added continuously for 5.5 hours. It was then refluxed for one hour, cooled to room temperature, slowly poured into 5 kg of crushed ice under stirring, and the upper oil layer was separated, washe...

example 3

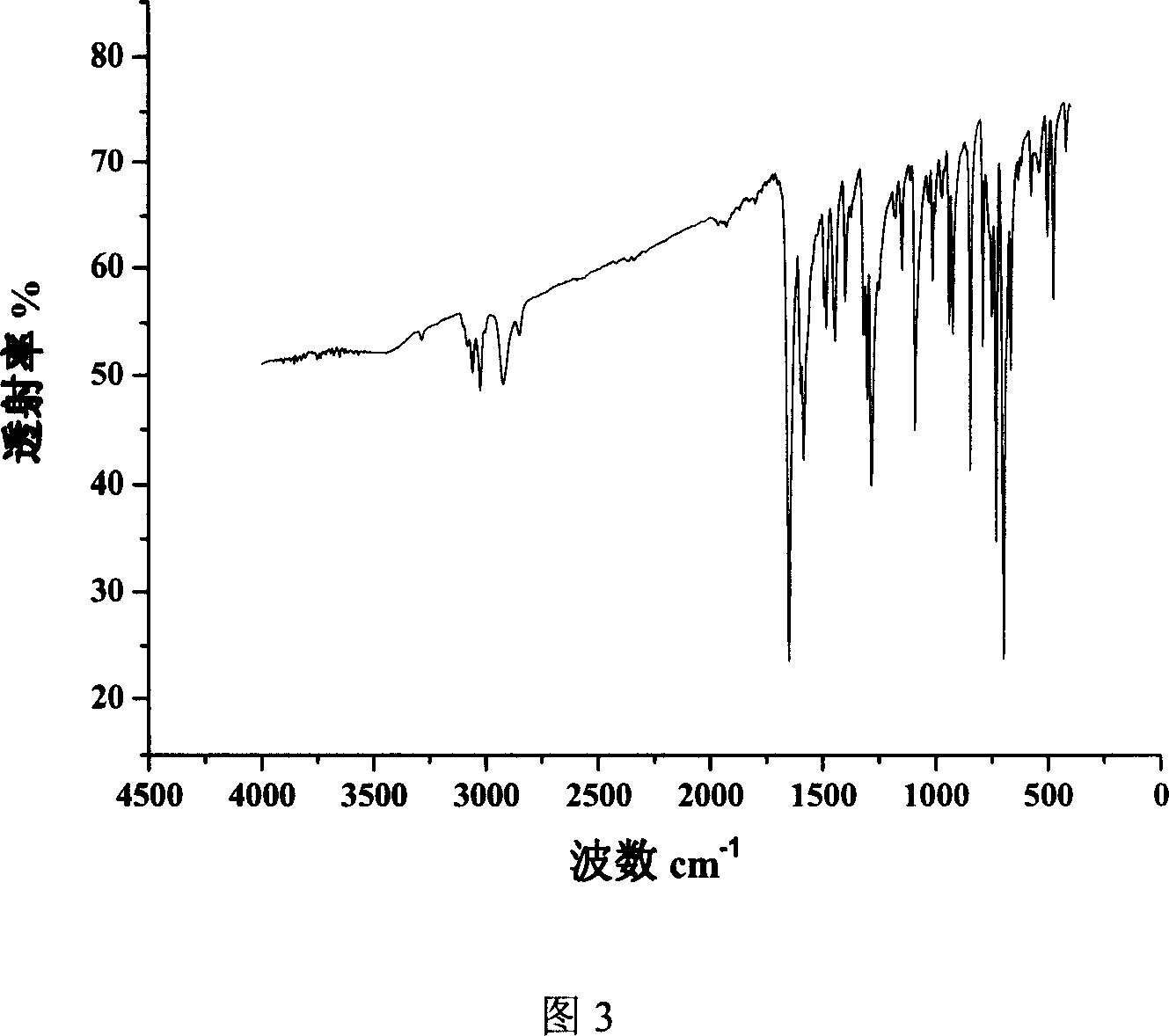

[0040] Example 3, the preparation of p-methylbenzoyl poly(styrene-methyl methacrylate) linear oligomer

[0041] Add 350ml of carbon disulfide to a 1L three-neck flask equipped with a stirrer, a separatory funnel with a calcium chloride drying tube, and a reflux condenser connected to an absorption gas device, and then add 25g of benzoyl peroxide and 150ml of benzene under stirring. Ethylene and 50ml of methyl methacrylate were heated to 60°C for about 4 hours to obtain a poly(styrene-methyl methacrylate) solution. Cool down to room temperature, add 140 g of anhydrous aluminum trichloride in batches under stirring and raise the temperature to 35°C. Under vigorous stirring, 110 g (93 ml) of p-toluoyl chloride was added dropwise. After the reaction started to release hydrogen chloride, the heating was stopped, and p-toluyl chloride was continued to be added for 3 hours. It was then refluxed for one hour, cooled to room temperature, slowly poured into 3 kg of crushed ice under s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap