Double shell microcapsule phase change material with paraffin compound as core and its preparing process

A technology of phase change materials and microcapsules, applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of high price of pure linear alkanes, restrictions on large-scale use, strict compatibility requirements, etc. , to achieve the effects of dense packaging, increased service life, and increased use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

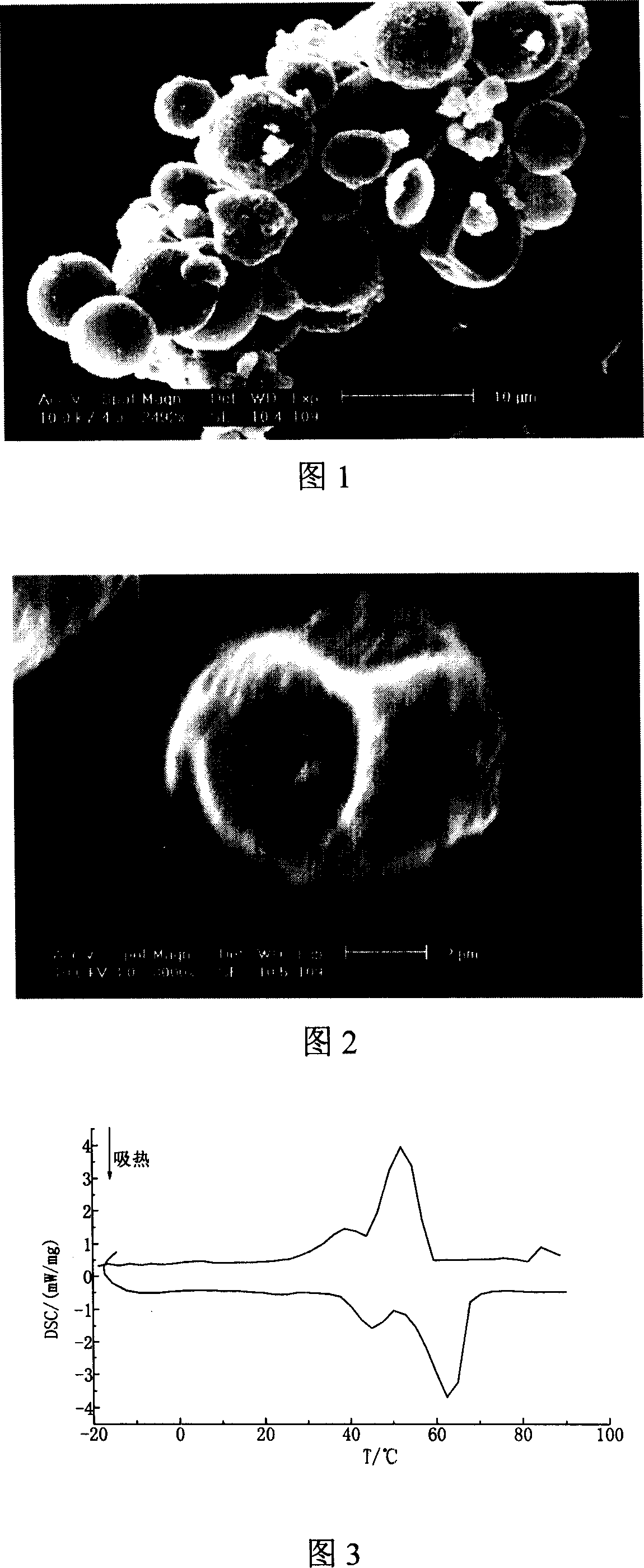

Embodiment 1

[0039] 1. Dissolve 0.3g of polypropylene glycol with a molecular weight of 2000 and 1.7g of TDI in 3.5g of cyclohexane, and dissolve with 20g of paraffin wax at 65°C.

[0040] 2. Add the above-mentioned core material solution into 60 g of deionized water containing 3.2 g of polyacrylic acid sodium salt with a molecular weight of 100,000, and emulsify for 15 minutes at 65° C. and 6,000 r / min to obtain a core material emulsion.

[0041] 3. Transfer the core material emulsion to a three-necked flask, add 10 g of an aqueous solution containing 0.8 g of ethylenediamine dropwise under the conditions of 65 ° C and 350 r / min, drop it in 20 minutes, and keep it warm for 1.5 hours.

[0042] 4. Add 2.4g of melamine and 4.2g of formaldehyde aqueous solution into deionized water, adjust the pH value to 7-8, raise the temperature to 70°C, and stir until the solution is transparent to obtain a melamine-formaldehyde prepolymer.

[0043] 5. Add the melamine-formaldehyde resin prepolymer into t...

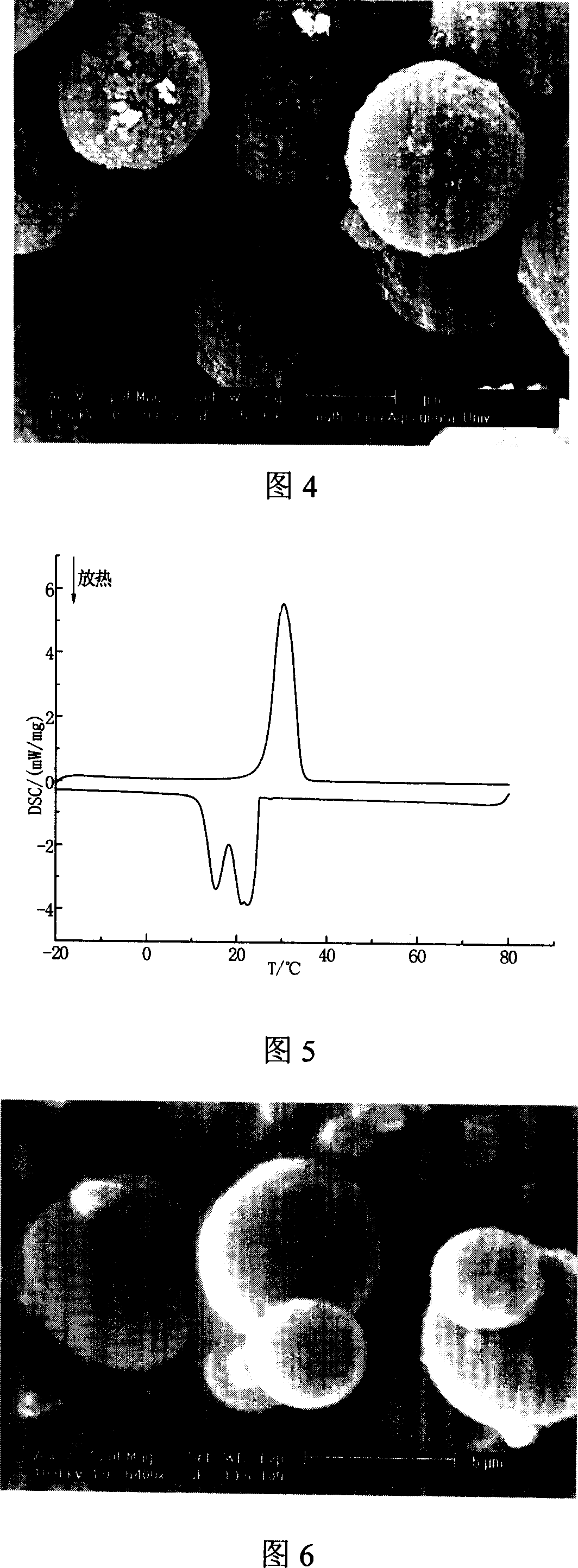

Embodiment 2

[0046]1. Dissolve 0.3g of polypropylene glycol with a molecular weight of 2000 and 1.6g of HDI in 3.3g of cyclohexane, and dissolve with 20g of n-octadecane at 65°C.

[0047] 2. Add the above-mentioned core material solution into 60 g of deionized water containing 3.2 g of polyacrylic acid sodium salt with a molecular weight of 150,000, and emulsify for 15 minutes at 35° C. and 7,000 r / min to obtain a core material emulsion.

[0048] 3. Transfer the core material emulsion to a three-necked flask, add 10 g of an aqueous solution containing 0.8 g of ethylenediamine dropwise under the conditions of 35 ° C and 350 r / min, drop it in 20 minutes, and keep it warm for 1.5 hours.

[0049] 4. Add 2.4g of melamine and 4.2g of formaldehyde aqueous solution into deionized water, adjust the pH value to 7-8, raise the temperature to 70°C, and stir until the solution is transparent to obtain a melamine-formaldehyde prepolymer.

[0050] 5. Add the melamine-formaldehyde resin prepolymer into th...

Embodiment 3

[0053] 1. Dissolve 0.35g of polypropylene glycol with a molecular weight of 2500 and 1.8g of TDI in 3.5g of cyclohexane, and co-dissolve with 20g of n-nonadecane at 38°C.

[0054] 2. Add the above-mentioned core material solution to 60 g of deionized water containing 3.6 g of polystyrene-maleic anhydride sodium salt with a molecular weight of 2,000,000, and emulsify for 20 minutes at 38° C. and 6,000 r / min to obtain a core material emulsion.

[0055] 3. Transfer the core material emulsion to a three-necked flask, add 10 g of an aqueous solution containing 0.7 g of ethylenediamine dropwise under the conditions of 38 ° C and 350 r / min, drop it in 20 minutes, and keep it warm for 1.5 hours.

[0056] 4. Add 2.4 g of melamine and 4.2 g of formaldehyde aqueous solution into deionized water, adjust the pH value to 7-8, raise the temperature to 80° C., and stir until the solution is transparent to obtain a melamine-formaldehyde prepolymer.

[0057] 5. Add the melamine-formaldehyde res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com