Low energy consumption production method of biological diesel oil

A technology of biodiesel and low energy consumption, which is applied to the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures. It can solve the problems of high equipment requirements, large esterification wastewater, and long reaction time, and achieve low requirements for reaction conditions. Energy consumption and the effect of saving water washing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

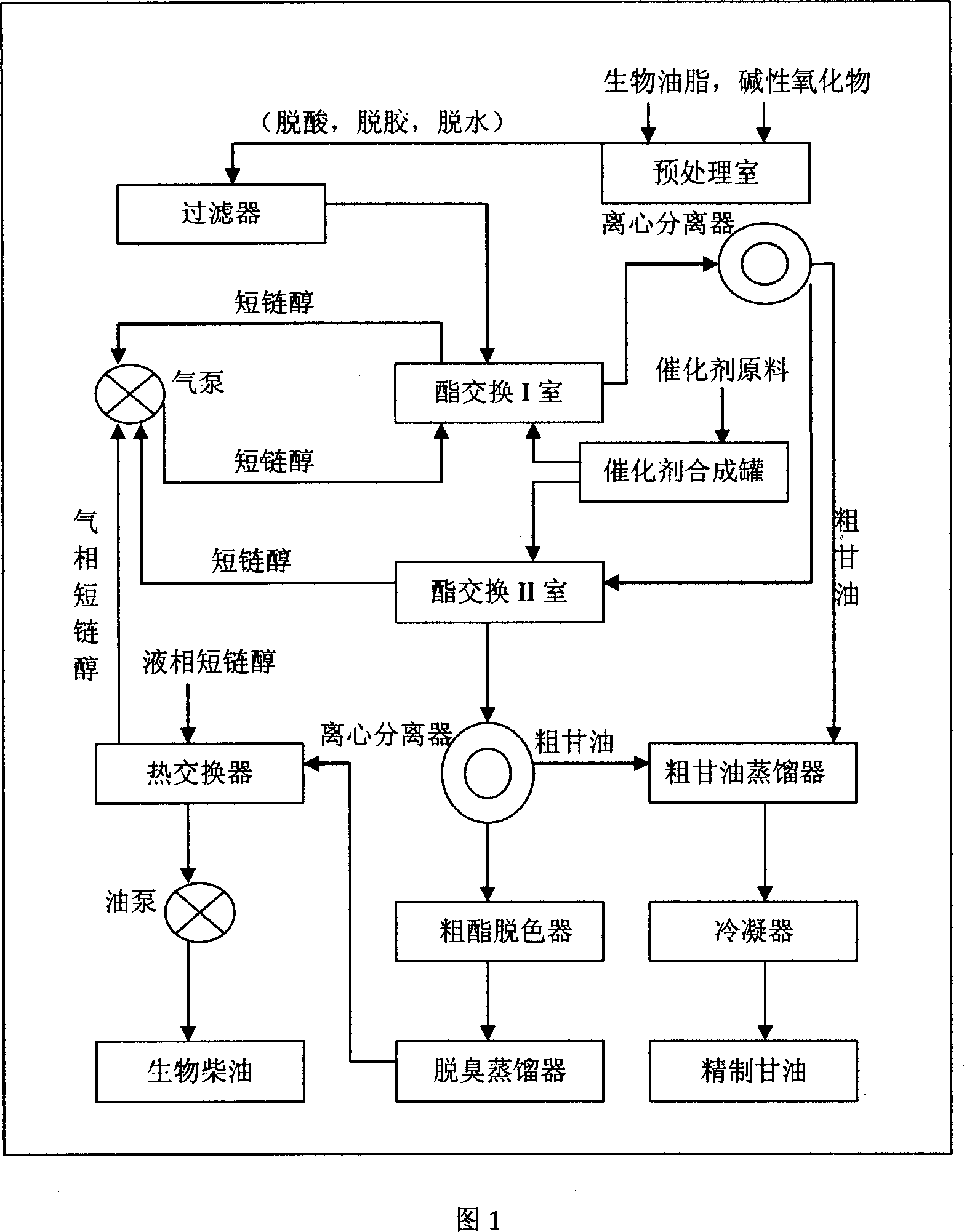

Image

Examples

example 1

[0034] A. The preparation stage

[0035] A-1. Pretreatment of waste cooking oil

[0036] A-1-1. Pretreatment of waste cooking oil Put 1 mole of waste cooking oil (the measured molecular weight of the waste cooking oil is 900g / mol, and the density is 0.926g / ml) and 45g of quicklime in the pretreatment chamber, heat and stir 15-30min, deacidification, degumming and dehydration of waste cooking oil; the reaction temperature is 343-373K;

[0037] A-1-2. filter the residue of the above reaction;

[0038] A-2. Preparation of Porous Composite Catalyst

[0039] A-2-1. CaO: CaCO 3 : NaOH: the molar ratio of clay is 3: 1: 3: 3, add the catalyst synthesis tank;

[0040] A-2-2. Calcining and pressing to form a porous composite catalyst; the calcination temperature is 1073-1473K; the calcination time is 20-30min;

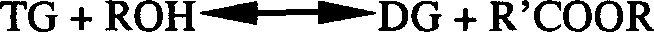

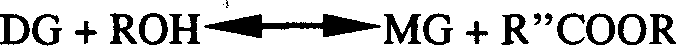

[0041] B. Reaction of bio-oils with short-chain alcohols

[0042] B-1. The first stage of transesterification pumps the pretreated waste cooking oil into the transesterifi...

example 2

[0050] A. The preparation stage

[0051] A-1. Pretreatment of rapeseed oil

[0052]A-1-1. Pretreatment of rapeseed oil Put 1 mole of rapeseed oil (measured molecular weight of waste edible oil is 882g / mol, density is 0.906g / ml), quicklime 12g is placed in the pretreatment chamber, heated and stirred 15-30min, deacidification, degumming and dehydration of waste cooking oil; the reaction temperature is 343-373K;

[0053] A-1-2. filter the residue of the above reaction;

[0054] A-2. Preparation of Porous Composite Catalyst

[0055] A-2-1. CaO: CaCO 3 : NaOH: the molar ratio of clay is 3: 1: 3: 3, add the catalyst synthesis tank;

[0056] A-2-2. Calcining and pressing to form a porous composite catalyst; the calcination temperature is 1073-1473K; the calcination time is 20-30min;

[0057] B. Reaction of bio-oils with short-chain alcohols

[0058] B-1. The first stage of transesterification pumps the pretreated waste cooking oil into the transesterification I chamber, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com