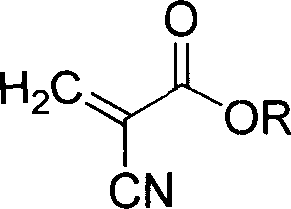

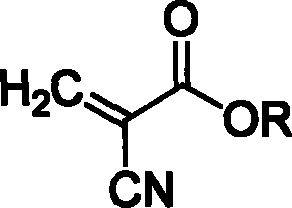

Photocured cyanoacrylate adhesives

A technology of cyanoacrylate and acrylate, which is applied in the field of ester copolymer adhesives, can solve the problems that the bonding performance needs to be improved and the brittleness of the adhesive is high, and achieve high bonding strength, fast curing ability, good adhesion The effect of knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare photocurable cyanoacrylate adhesive according to the ratio in the table below, take 134.80g of methyl a-cyanoacrylate, add 0.20g of ferrocene, photocuring initiator 2-hydroxy-2-methyl-1-benzene Base-1-acetone 5.00g, dimethoxyphenyl acetophenone 5.00g, after dissolving, add isobornyl methacrylate 40.00g, 1,6-hexanediol diacrylate 9.00g, methacrylate phosphoric acid 3.00 g of ester and 3.00 g of Deqian 1121 adhesion promoter were mixed uniformly to obtain light-curable cyanoacrylate adhesive.

[0022] components

Embodiment 2

[0024] Prepare photocurable cyanoacrylate adhesive according to the ratio in the table below, take 172.60g of α-methyl cyanoacrylate, 7.20g of α-allyl cyanoacrylate, add 0.20g of methyl ferrocene, phthalate Formic anhydride 1.00g, photocuring initiator 2,4,6-trimethylbenzoyldiphenylphosphine oxide 3.00g, after dissolving, add propylene glycol diacrylate 6.00g, trimethylolpropane triacrylate 8.00g, Deqian 1121 adhesion promoter 2.00g, mixed evenly to obtain photocurable cyanoacrylate adhesive.

[0025] components

Embodiment 3

[0027] Prepare photocurable cyanoacrylate adhesive according to the ratio in the table below, take 161.60g of ethyl cyanoacrylate, add 0.20g of ferrocene, 1.60g of phthalic anhydride, photocuring initiator dimethoxy 2.00g of phenylacetophenone, 2.00g of 1-hydroxycyclohexyl phenone, after dissolving, add 20.00g of isobornyl methacrylate, 10.00g of dipropylene glycol diacrylate, 2.60g of Deqian 1121 adhesion promoter, mix Evenly, a photocurable cyanoacrylate adhesive is obtained.

[0028] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com