Rare-earth alumo silicate matrix fluorescent material, and preparation method

A technology of fluorescent materials and silicates, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem that it is not easy to accurately control the composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] 2) Preparation of composite sol: according to the fixed ratio of atomic ratio Al:Si=2:1, Si is replaced by SiO 2 added to the alumina sol in the form of SiO 2 The size is 40-80nm; Ca, Sr, Ba are added to the alumina sol in the form of nitrate according to the stoichiometric ratio; Eu is added to the alumina sol in the form of europium nitrate, and the number range is the number of atomic moles: 0.01 ≤x≤0.1; the above composite sol is mechanically stirred for 3-5 hours, and then adjusted to pH=1-3 with aqueous nitric acid solution to obtain a rare earth composite sol without precipitation.

[0015] 3) High temperature firing of xerogel particles:

[0016] The above rare earth composite sol is atomized and granulated on a commercial spray dryer to obtain xerogel particles. Compressed air temperature is 110°C-130°C, dry air volume is 130m 3 / h-150m 3 / h, material flow 1.3L / h-1.5L / h conditions to prepare xerogel particles; 2 +5%H 2 Burn in the mixed gas for 3-5 hours....

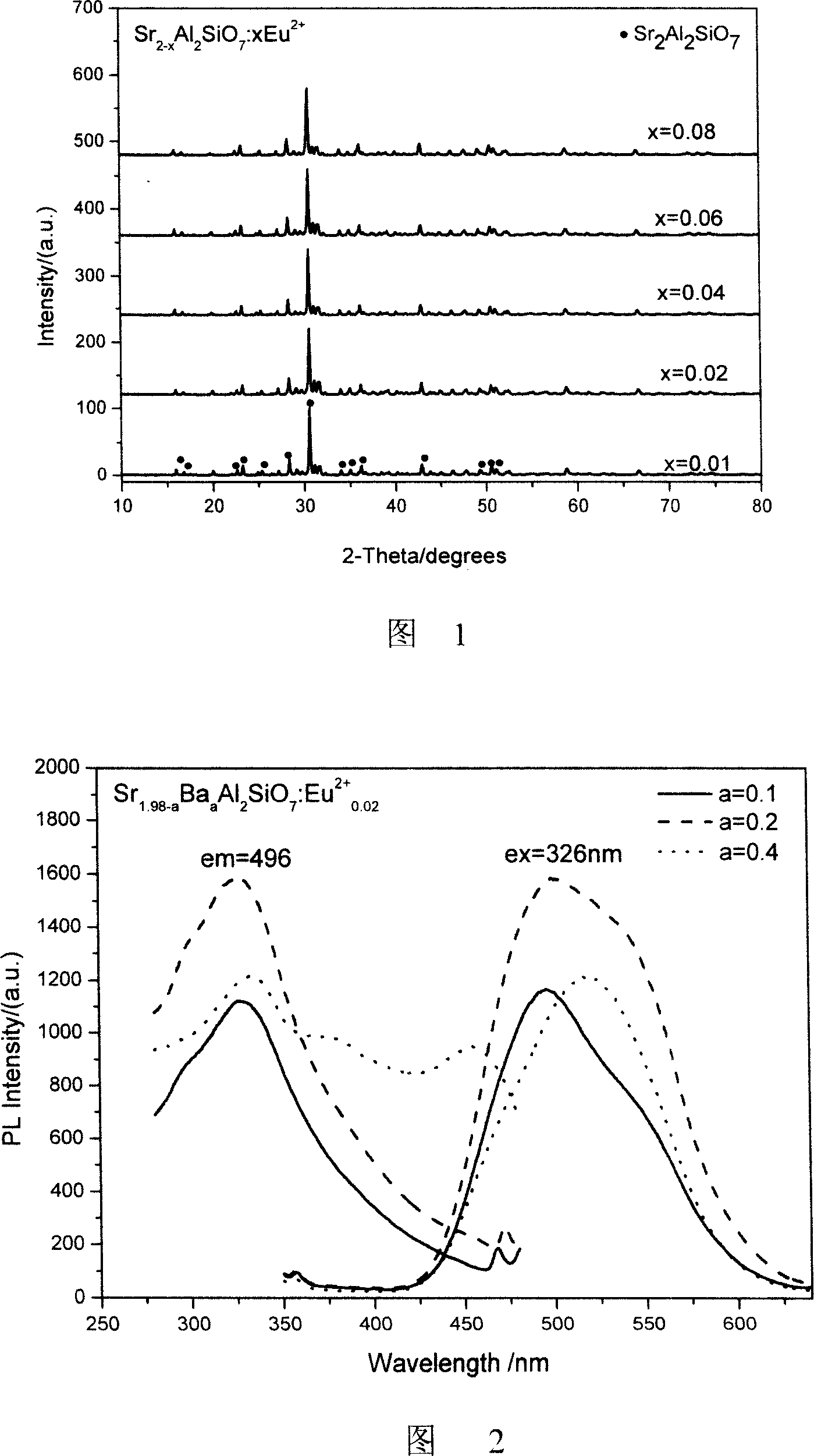

example 1

[0019] According to the ratio of mass ratio alumina: water = 3: 97, the pseudo-boehmite with a purity of 95% is mixed with distilled water, and under the condition of mechanical stirring, it is titrated to pH = 1-3 with a concentration of 30% nitric acid aqueous solution , that is, to obtain alumina sol; according to the fixed ratio of atomic ratio Al: Si = 2: 1, SiO with a size of 40nm 2 Add the alumina sol in the form of particles; divide the alumina sol into 5 parts, and add the rare earth ion Eu into the alumina sol in the form of europium nitrate. 0.02, 0.04, 0.06, 0.08; Sr is added to the alumina sol in the form of strontium nitrate, and the amount added is according to the provided chemical formula Sr 2-x al 2 SiO 7 Metering and mechanical stirring for 3 hours to obtain a composite sol; the atomization parameters of the composite sol are set as follows: the compressed air temperature is 110°C, and the dry air volume is 130m 3 / h, the material flow is 1.3L / h, to obtai...

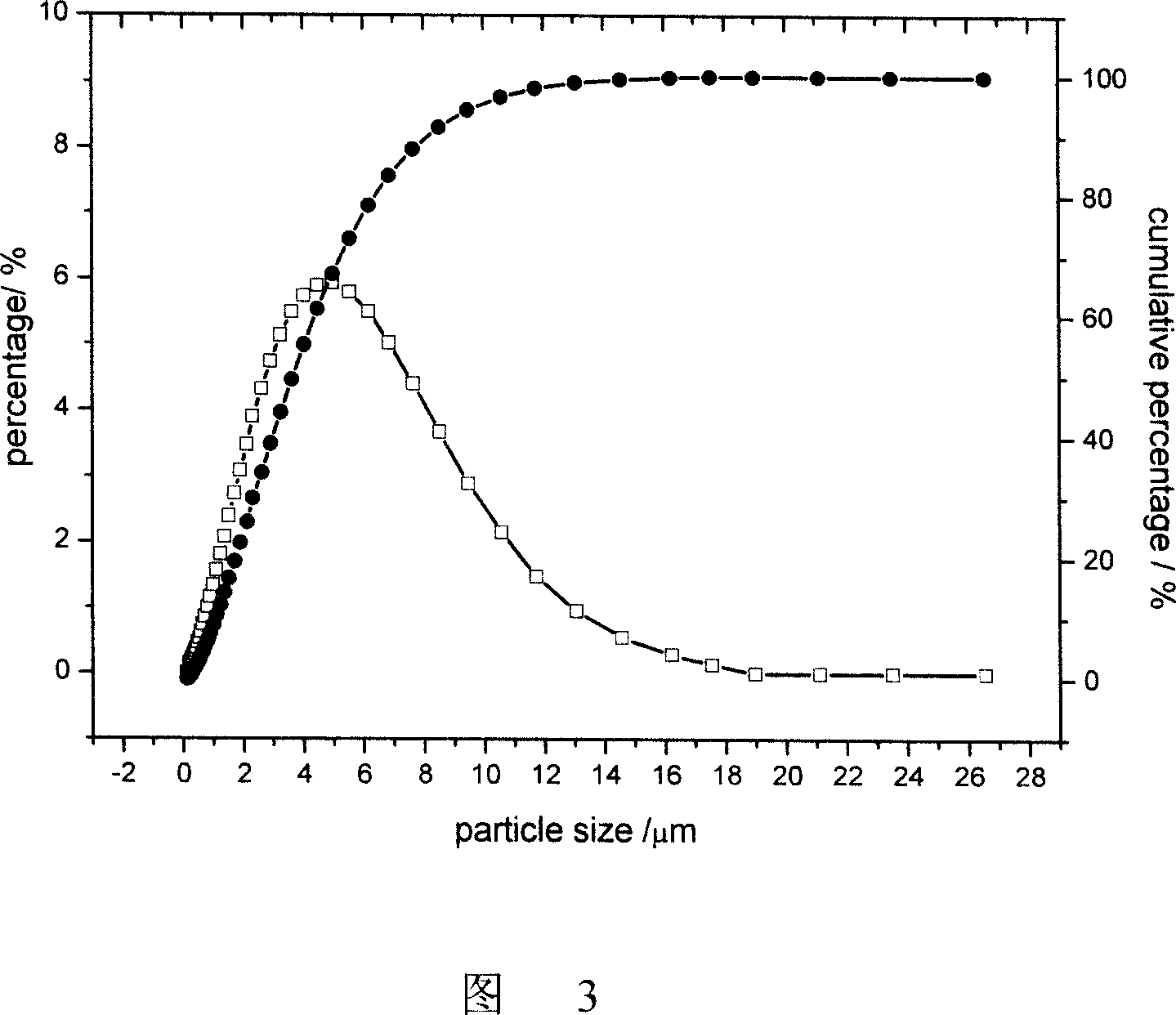

example 2

[0021] According to the ratio of mass ratio alumina: water = 4: 96, the pseudo-boehmite with a purity of 95% is mixed with distilled water, and under the condition of mechanical stirring, it is titrated to pH = 1-3 with a concentration of 30% nitric acid aqueous solution , that is, to obtain alumina sol; according to the fixed ratio of atomic ratio Al:Si=2:1, SiO with a size of 60nm 2 Add the alumina sol in the form of particles; the rare earth ion Eu is added to the alumina sol in the form of europium nitrate, and the amount added is x=0.02 according to the number of atomic moles; divide the previous alumina sol into 3 parts, Sr and Ba Add to the alumina sol in the form of strontium nitrate and barium nitrate respectively, and the amount added is according to the chemical formula provided by Sr 1.98-a Ba a al 2 SiO 7 Metering, where a = 0.1, 0.2, 0.4; mechanically stirred for 4 hours to obtain a composite sol; the atomization parameters of the composite sol are set as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com