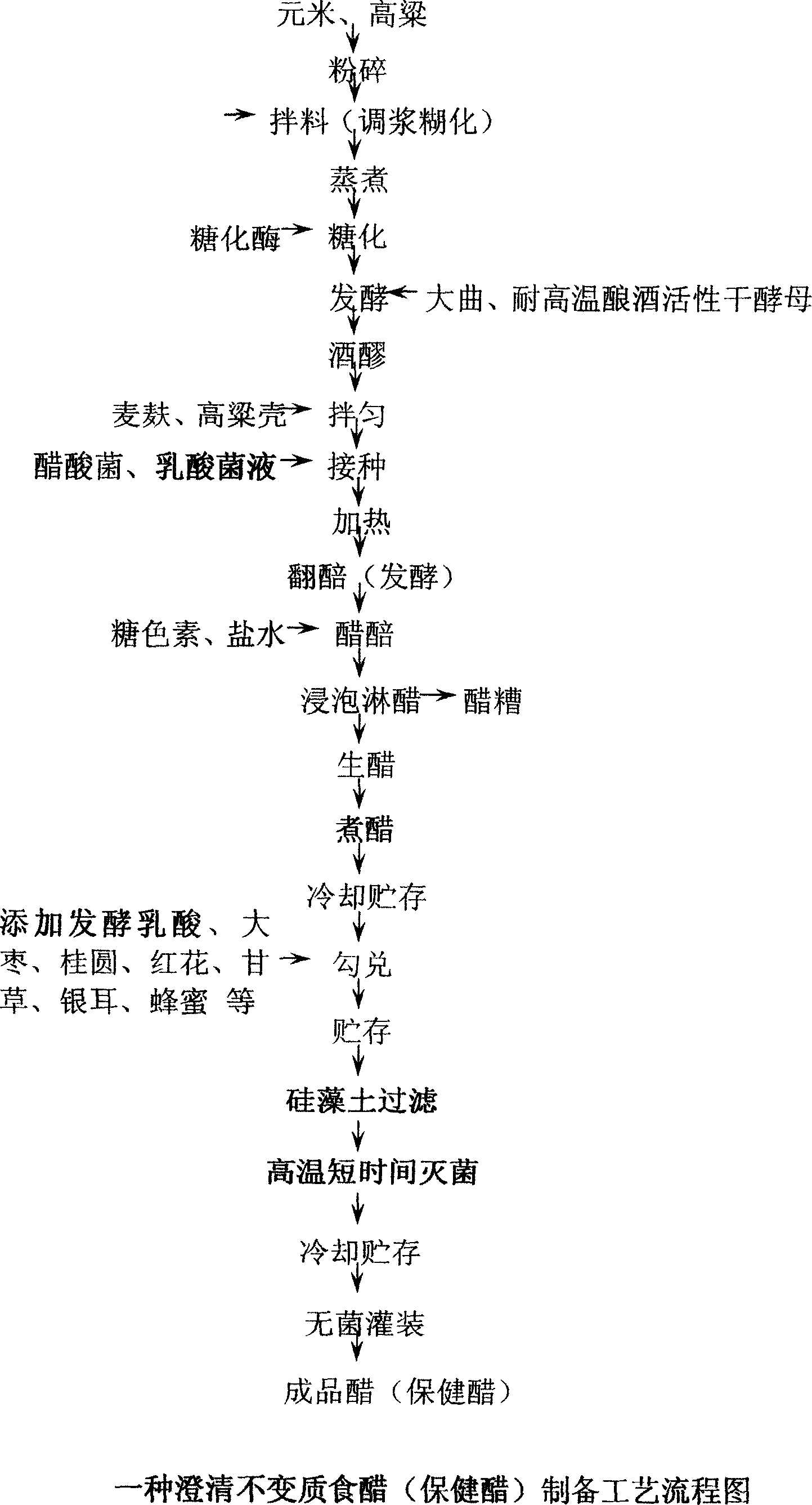

Preparation process for clarifying quality-keeping vinegar (health vinegar)

A preparation process, a technology for health-care vinegar, applied in the preparation of vinegar, biochemical equipment and methods, microorganisms, etc., can solve problems such as reduction, and achieve the effects of lowering serum cholesterol, delaying aging, and reducing bacterial pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. The preparation process of lactic acid bacteria culture solution is:

[0023] (1). Strain activation: connect the preserved original species Lactobacillus delbrueckii to 10ml5 0 In the test tube medium of Bx wort, culture at 45°C for 24h. It can be transferred several times appropriately.

[0024] (2). First-level seed culture: Put the above-mentioned test tube culture solution into a triangular flask containing 200ml culture solution. The composition of the culture medium is: wort 6~8 0 Bx, yeast extract 1g / L, natural pH. Sterilize for 20-25 minutes at a gauge pressure of 90kPa. After inoculation, incubate at 48-50°C for 12 hours, the pH drops to 3.5, add a small amount of sterilized calcium carbonate, and continue to incubate for 10-12 hours.

[0025] (3) Preparation of sugar solution and yeast mud: take the saccharification solution in production, and then measure a small amount of yeast mud in the alcohol fermentation mash that has been fermented for 72 hours, add it...

Embodiment 2

[0039] After pulverizing the main raw material Yuan rice and sorghum rice into powder, add water to make a powder slurry and add 5-10U / g raw material starch amount of high-temperature α-amylase, heat up to 85℃~92℃, liquefy for 10~15min, then heat up Inactivate the enzyme at 100°C for 5 minutes, then cool down to 65°C, pour it into the glucoamylase tank, and add 6-8U / g raw starch glucoamylase. After saccharification at 63°C for 1.5h, cool down to 30°C and add 10% Daqu and 0.15% Saccharomy cerevisiae (Saccharomy cerevisiae) were expanded by alcohol fermentation at 33°C for 64 hours to obtain a mash with 8% (v / v) alcohol concentration. Put the wine mash into the acetic acid fermentation tank, and add the auxiliary materials wheat bran, sorghum and 1% cultured mature acetic acid bacteria (AS.1.01) solution according to the ratio of main ingredients and auxiliary ingredients of 1:3, and add 2% according to the implementation Example 1: Preparation process of lactic acid bacteria cultur...

Embodiment 3

[0041] After pulverizing the main raw material Yuan rice and sorghum rice into powder, add water and adjust into a powder slurry, high temperature α-amylase, liquefy by heating for 10-15 minutes, inactivate enzyme at 100°C for 5 minutes, cool down to 65°C, add glucoamylase After saccharification for 1.5 hours, cool down to 30°C, add 10% Daqu and 0.2% of high-temperature resistant brewing active dry yeast (Saccharomy Cerevisiae) expanded wine mother, and alcoholic fermentation at 33°C for 64h to obtain 7.5% (v / v) Alcoholic mash. Put the wine mash into the acetic acid fermentation tank, and add the auxiliary materials wheat bran, sorghum and 1% cultured mature acetic acid bacteria (AS.1.01) solution according to the ratio of main ingredients and auxiliary ingredients of 1:2.5, and add 0.5% according to the implementation Example 1: Preparation process of lactic acid bacteria culture broth. Expanded culture broth of lactic acid bacteria (Lactobacillus delbrueckii), heated and fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com