Nd-doped potassium yittrium tungstate laser crystal growth method and growth device

A laser crystal and growth method technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of limited crystal size, low crystal quality, slow growth speed, etc., to achieve improved characteristics, improved growth process, Avoid the effects of an excessively long growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

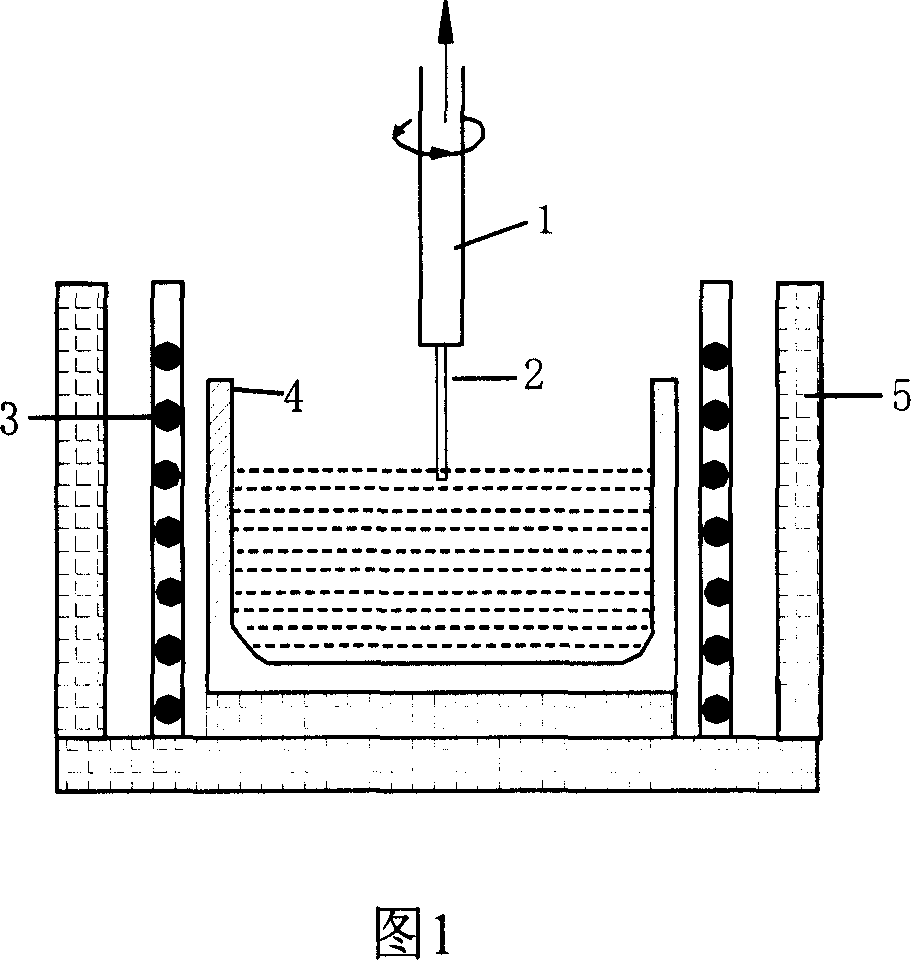

Method used

Image

Examples

Embodiment 1

[0026] With 15mol% K 2 W 2 o 7 , 35mol% K 2 WO 4 And 0.2mol% KF as joint flux. Carry out batching according to following reaction formula:

[0027] K 2 CO 3 +2WO 3 = K 2 W 2 o 7 +CO 2

[0028] 4WO 3 +(1-x)Y 2 o 3 +xNd 2 o 3 +K 2 CO 3 = 2KNd x Y 1-x (WO 4 ) 2 +CO 2

[0029] Raw material Y 2 o 3 、WO 3 、K 2 CO 3 、Nd 2 o 3 According to Nd x :KY 1-x (WO 4 ) 2 The molar ratio represented by the chemical formula is weighed, put into a corundum mortar, ground and mixed evenly, pressed into a sheet with a hydraulic press at a pressure of 3.0 tons per square centimeter, and put into a platinum crucible of Φ75mm×85mm, and the platinum crucible is placed in After sintering at 1000°C for 20 hours in the muffle furnace for solid-state reaction, take it out and re-grind the tablet, then put it into a larger Φ90mm×100mm platinum crucible, and put the platinum crucible in a molten salt pulling growth furnace , while connecting with Nd:KY(WO 4 ) 2 The seed...

Embodiment 2

[0032] Using 5mol% K 2 W 2 o 7 , 45mol% K 2 WO 4 And the KCl of 0.5mol% is used as joint fluxing agent, carries out batching according to the reaction formula given in embodiment 1. Raw material Y 2 o 3 、WO 3 、K 2 CO 3 、Nd 2 o 3 According to Nd x :KY 1-x (WO 4 ) 2 The molar ratio represented by the chemical formula is weighed, put into a corundum mortar, ground and mixed evenly, pressed into a sheet with a hydraulic press at a pressure of 3.0 tons per square centimeter, and put into a platinum crucible of Φ60mm×70mm, and the platinum crucible is placed in After sintering at 1000°C for 20 hours in the muffle furnace for solid-state reaction, take out the re-grinded tablet and put it into a larger Φ70mm×80mm platinum crucible, and put the platinum crucible together in molten salt for pulling growth In the furnace, at the same time connect the Nd:KY (WO 4 ) 2 The seed crystal rod of the seed wafer is connected to the ceramic rod and then centered, and then penetr...

Embodiment 3

[0034] With 10mol% K 2 W 2 o 7 , 40mol% K 2 WO 4 And the KF of 1.0mol% is used as joint flux, carries out batching according to the reaction formula given in embodiment 1. According to the operation method of Example 2, after the steps of raw material weighing, grinding, tableting, crucible loading, sintering, regrinding, re-pressing, and crucible reloading, the platinum crucible was placed in a molten salt pulling growth furnace, Connect with Nd:KY(WO 4 ) 2 The seed crystal rod of the seed wafer is connected to the ceramic rod and then centered, and then penetrated into the bulk crystal material Nd in the platinum crucible 3+ :KY(WO 4 ) 2 At 5mm above, seal the furnace door of the molten salt pulling growth furnace and vacuumize it, then fill it with a small amount of nitrogen, start to heat up to around 1090°C and fully melt for 8 hours, and keep stirring to fully melt the polycrystalline material, keep the temperature at 1110°C 4 hours, and then began to slowly coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com