Thermal regulation of an ion implantation system

a technology of ion implantation and thermal regulation, which is applied in the direction of ion beam tubes, electric discharge lamps, nuclear engineering, etc., can solve the problems of beam space charge, inefficient beam transport of standard ions, and limitations in physics, so as to achieve the effect of reducing the charge of the beam space charg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

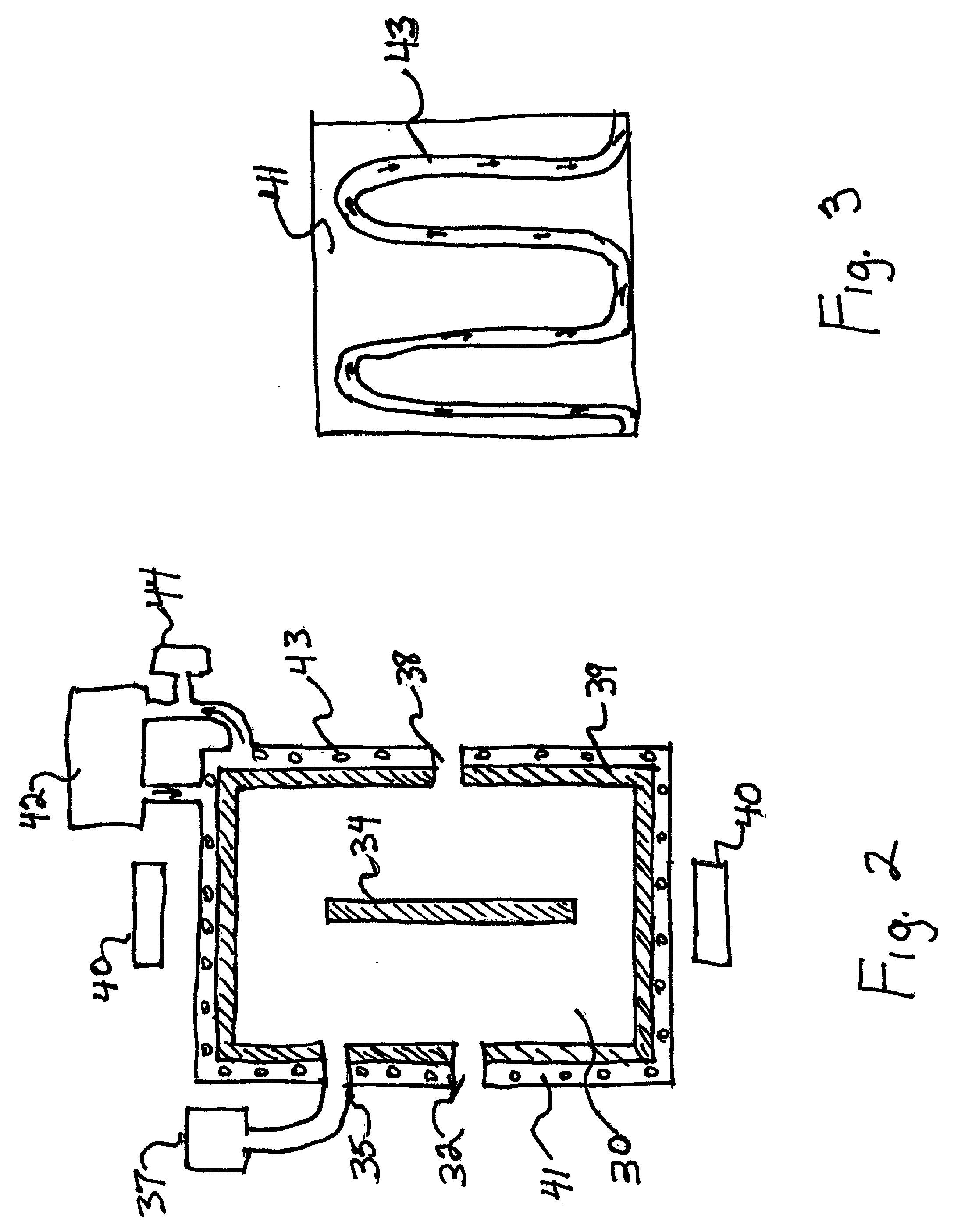

[0042] The present invention provides for temperature control means in an ion implanter to reduce the chance of accidental exposure to harmful ion source material and to provide a more efficient and cost effective means for cooling the ion implanter before servicing or replacing material in an ion source.

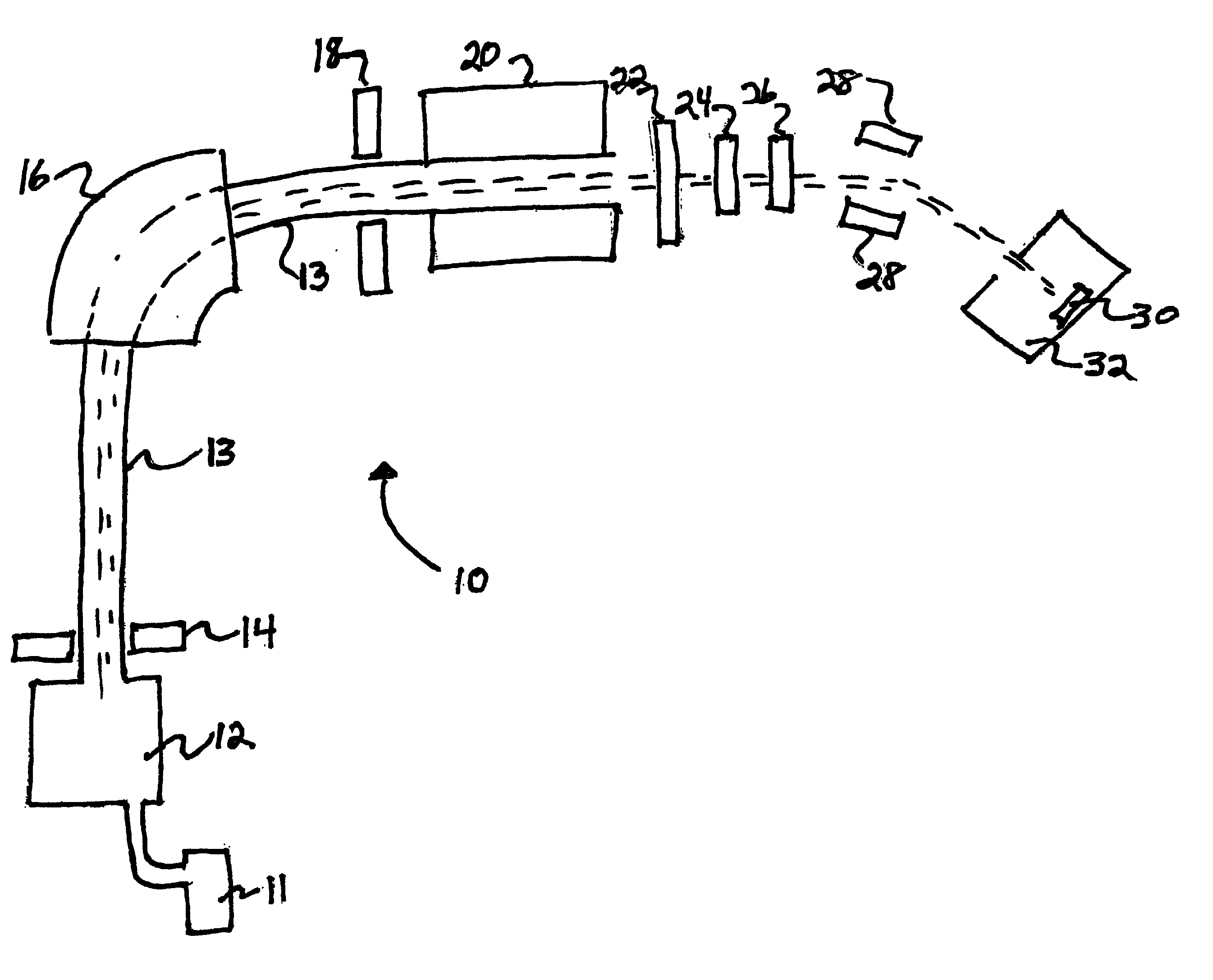

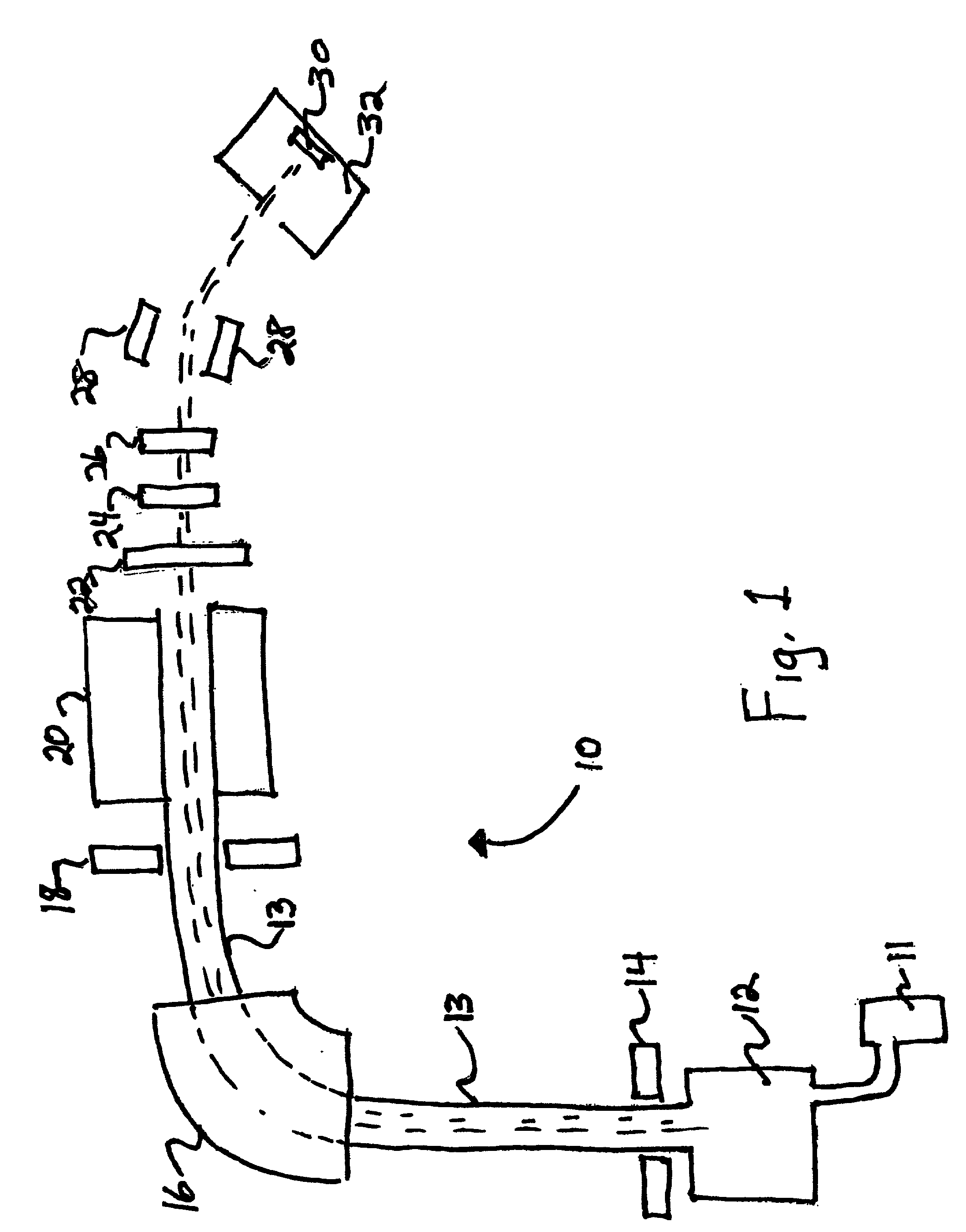

[0043] As depicted in FIG. 1, an ion implanter 10 typically includes an ion source 12 that generates ions. The ions are drawn by extracting electrodes 14 and their mass is analyzed by a separating electromagnet 16. The ions are separated by apertures 18 and may be further accelerated or decelerated by accelerators 20 to the final energy. A beam of ions is converged on a sample 30, may also be positioned in a target chamber 32, by quadrupole lens 22 and scanned by scanning electrodes 24 and 26 to uniformly distribute the ion beam on the target 30. Deflection electrodes 28 are designed to deflect the ion beam in order to eliminate uncharged particles caused by collision with residual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com