Fabrication system and a fabrication method of light emitting device

a technology of light-emitting devices and fabrication systems, which is applied in the direction of vacuum evaporation coating, crystal growth process, coating, etc., can solve the problems of inability to perform photolithography processes after deposition, easy oxidation and deterioration of el materials, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

[0063] Embodiment

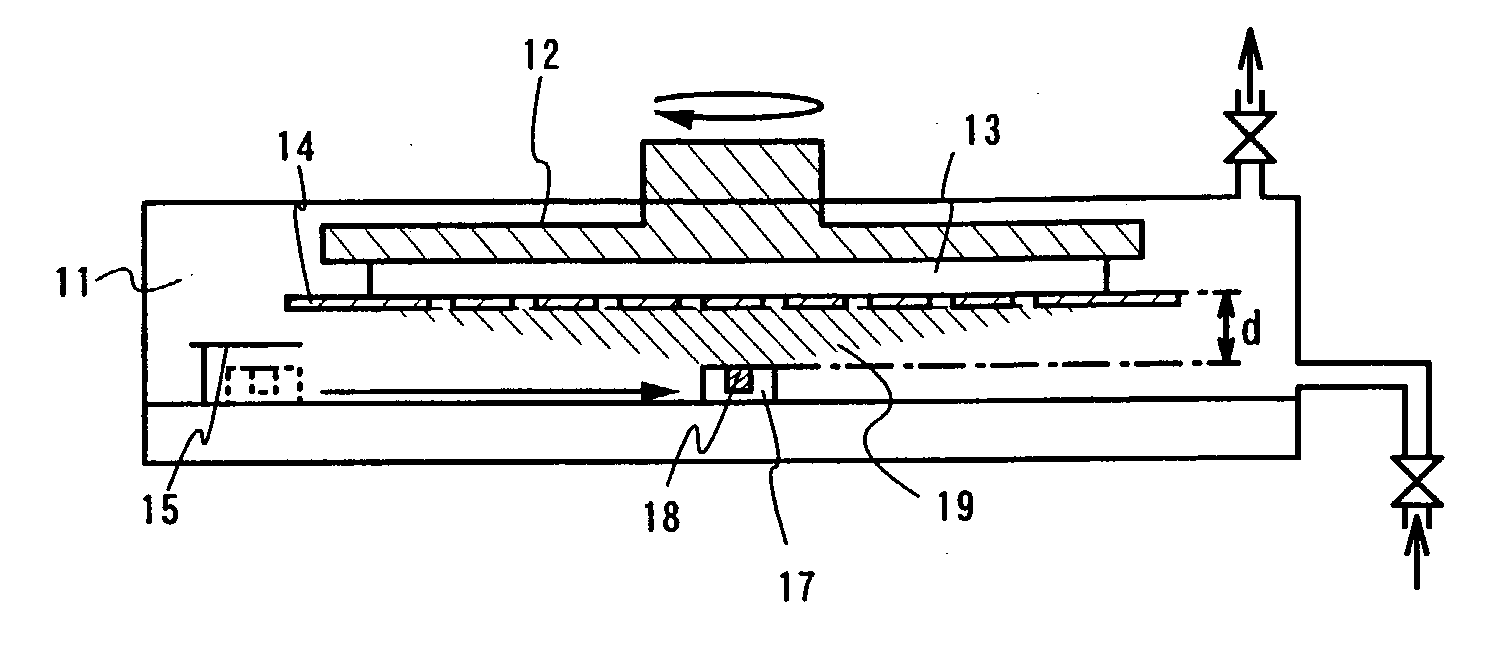

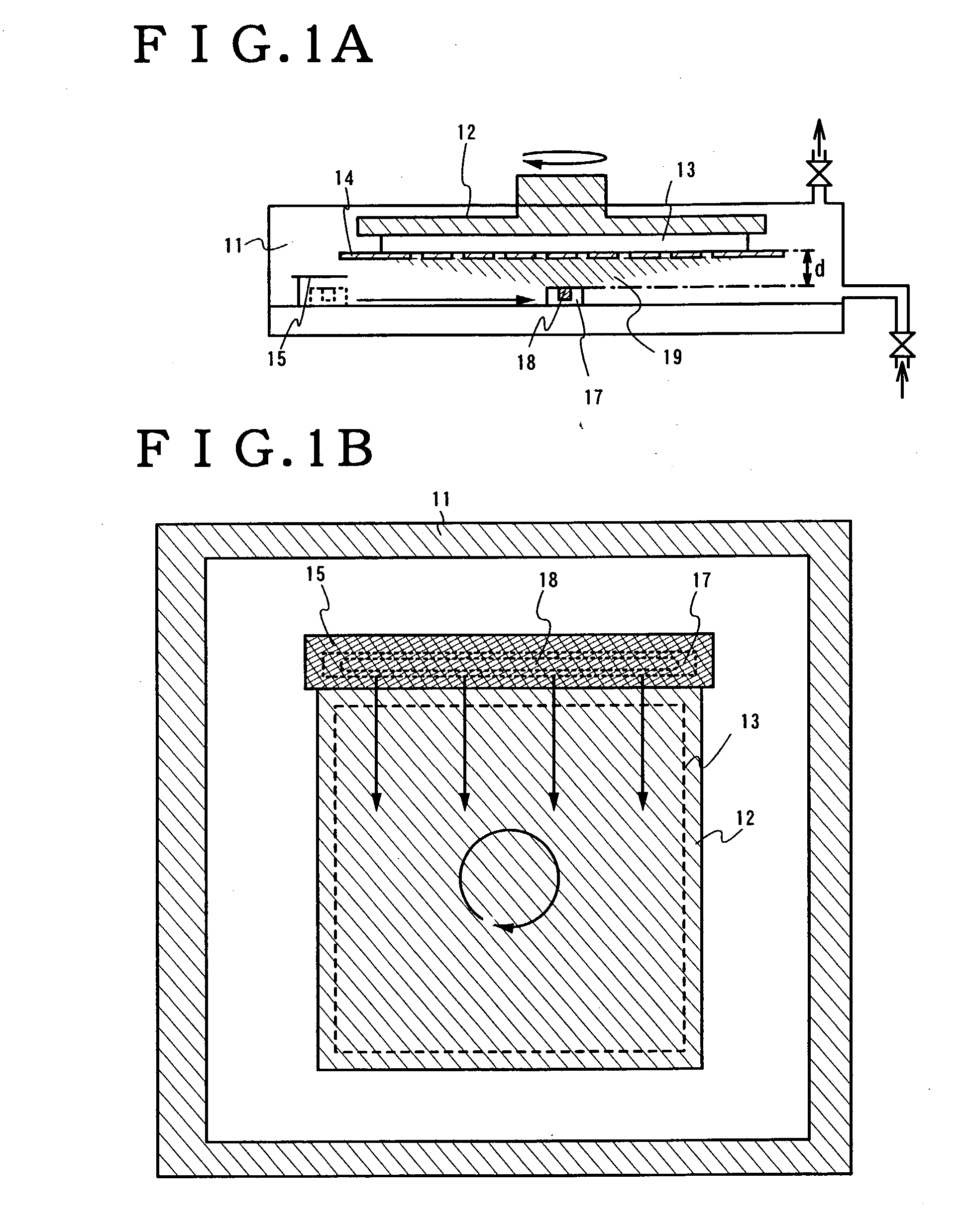

[0064] FIGS. 1A and 1B show a deposition apparatus of the invention. FIG. 1A is a cross section, and FIG. 1B is a top view.

[0065] In FIGS. 1A and 1B, reference numeral 11 denotes a film-formation chamber, reference numeral 12 denotes a substrate holder, reference numeral 13 denotes a substrate, reference numeral 14 denotes a mask, reference numeral 15 denotes a deposition shield (deposition shutter), reference numeral 17 denotes an evaporation source holder, reference numeral 18 denotes an evaporation material, and reference numeral 19 denotes an evaporated evaporation material.

[0066] Evaporation is conducted in the film-formation chamber 11 vacuumed at a vacuum degree of 5.times.10.sup.-3 Torrs (0.665 Pa) or below, preferably vacuumed to 10.sup.-4 to 10.sup.-6 Pa. In evaporation, the evaporation material is evaporated (vaporized) by resistance heating beforehand. A shutter (not shown) is opened when evaporation, which causes the material to fly in the direction of ...

example

Example 1

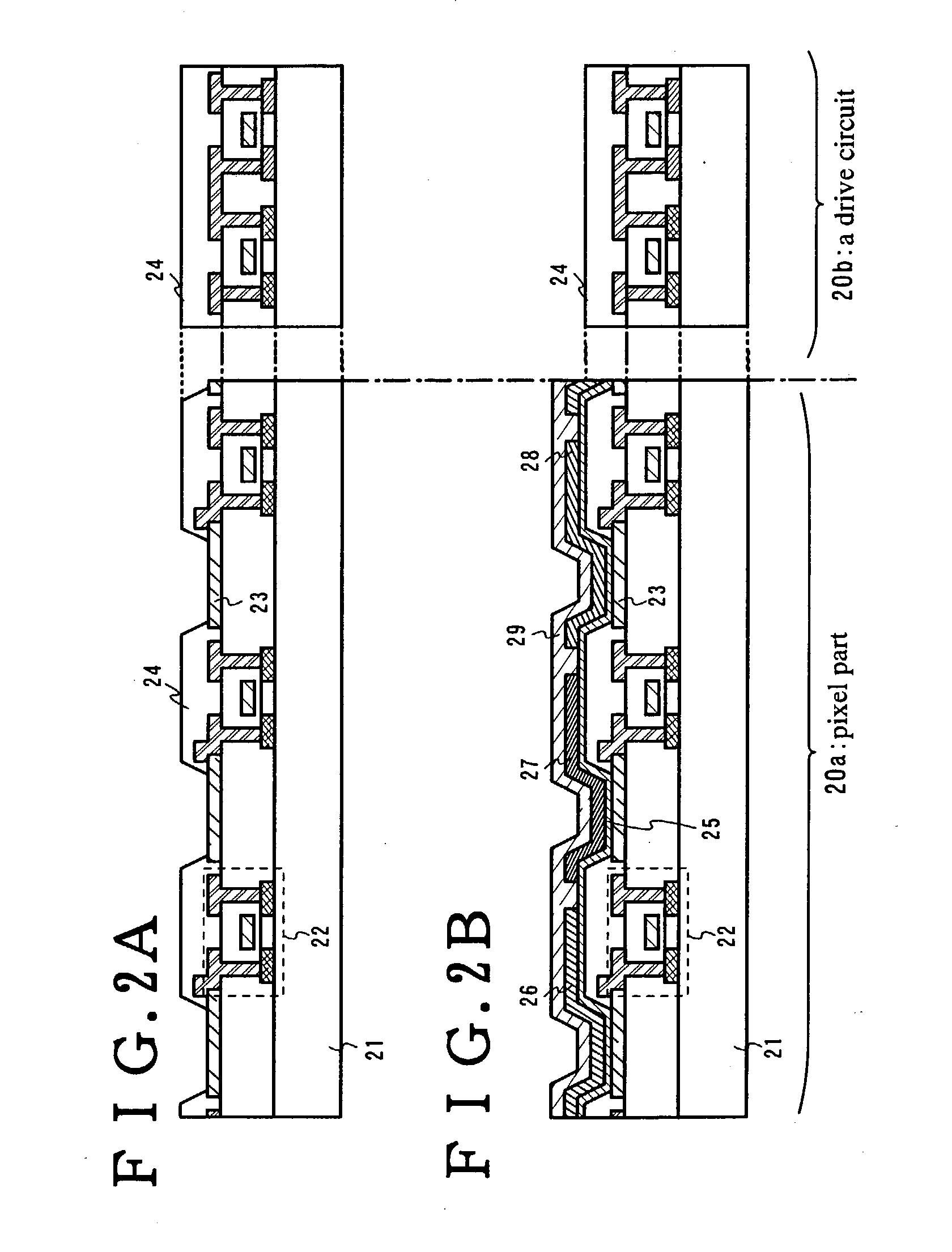

[0080] Here, the process steps of fabricating an active matrix light emitting device having a pixel part and a drive circuit on the same substrate and including an EL element is exemplified and described in FIGS. 2A and 2B.

[0081] First, as shown in FIG. 2A, a thin film transistor (hereafter, it is called a TFT) 22 is formed over a substrate 21 having an insulated surface by publicly known fabrication process steps. In a pixel part 20a, an n-channel TFT and a p-channel TFT are formed. Here, the p-channel TFT for feeding current to an organic light emitting element is illustrated in the drawing. It is acceptable that the TFT for feeding current to the organic light emitting element is the n-channel TFT or the p-channel TFT. In a drive circuit 20b disposed around the pixel part, the n-channel TFT, the p-channel TFT, and a CMOS circuit that complementally combines them are formed. Here, an example is shown in which an anode 23 formed of a transparent conductive oxide film (ITO ...

example 2

[0093] FIG. 3 is a diagram illustrating the appearance of the top view of an E1 module. In a substrate (it is also called a TFT substrate) 35 where a countless number of TFTs are formed, a pixel part 30 for display, drive circuits 31a and 31b for driving the pixels in the pixel part, connecting parts for connecting a cathode disposed over an EL layer to interconnect wiring lines, and terminal parts 32 for bonding an FPC to connect external circuits are disposed. The module is sealed with a substrate for encapsulating the EL element and a sealing material 34.

[0094] In FIG. 3, the cross section of the pixel part is not defined particularly. Here, the cross section shown in FIG. 2B is exemplified. The module shown in FIG. 3 is a product after the encapsulation process in which a protection film or an encapsulation substrate was bonded to the product having the cross sectional structure shown in FIG. 2B.

[0095] An insulating film is formed over the substrate, and the pixel part and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com