Low contamination components for semiconductor processing apparatus and methods for making components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

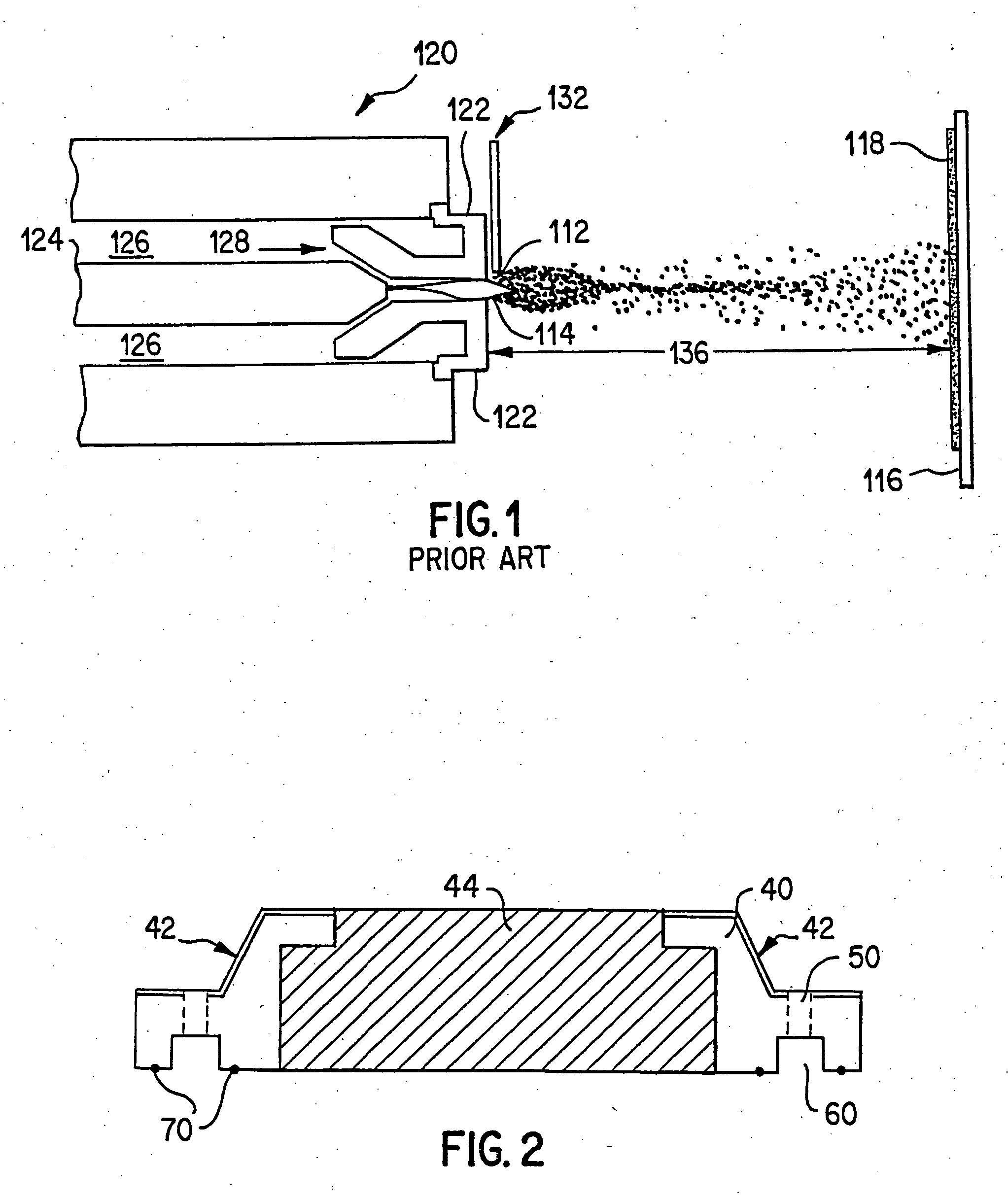

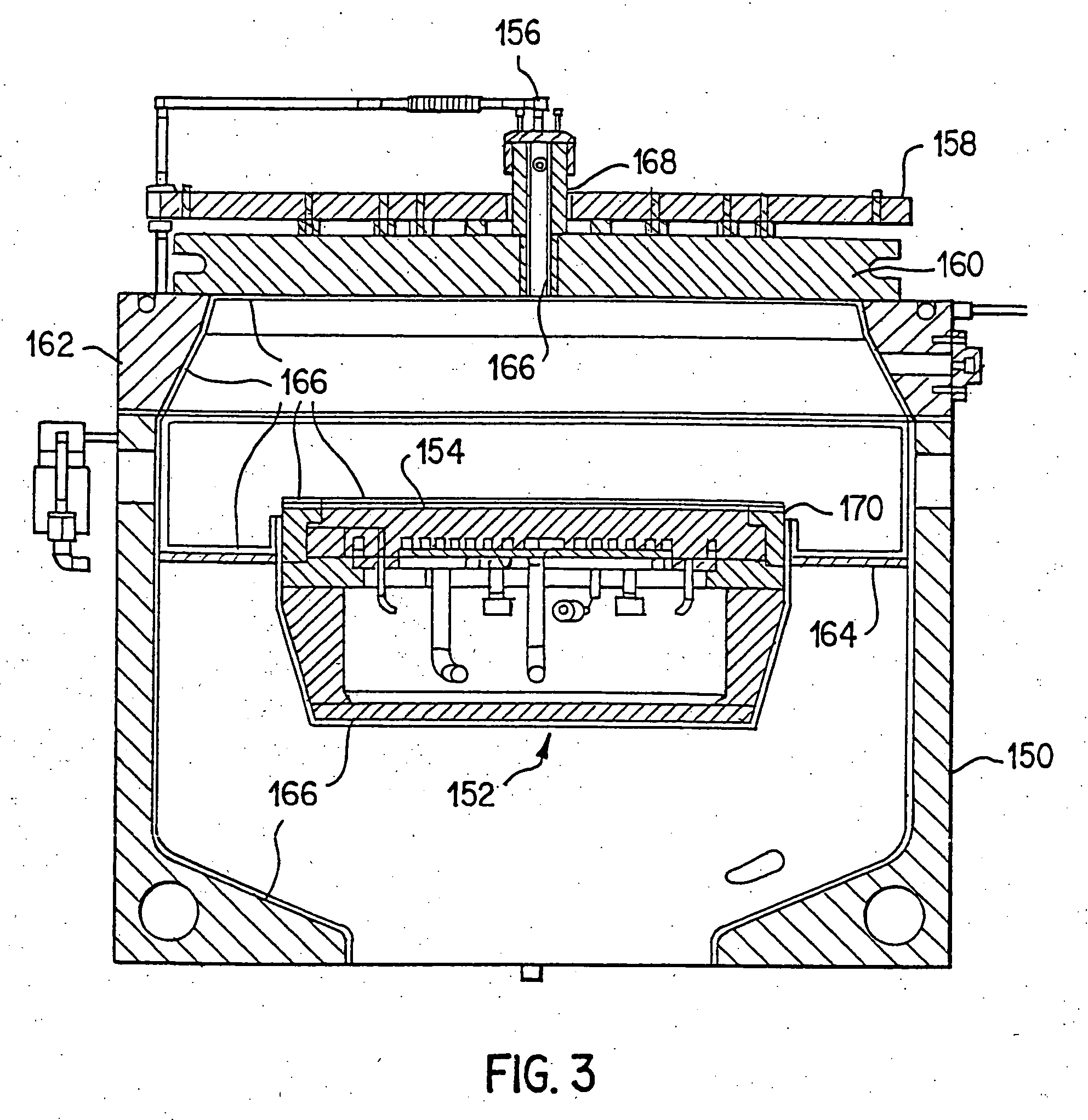

[0030] The invention provides components that have wear resistance with respect to physical and chemical attack by plasmas generated in semiconductor material processing apparatuses. As used herein, the term “wear resistant” includes, but is not limited to, erosion, corrosion and / or corrosion-erosion resistance. The components are composed of wear resistant ceramic materials.

[0031] In some exemplary embodiments, the components include coatings composed of erosion resistant ceramic materials formed on substrates. For example, the components can include substrates and one or more erosion resistant ceramic coatings formed on the substrates. The coatings resist erosion and, being non-metallic materials, are also resistant to corrosion and / or corrosion-erosion.

[0032] In other exemplary embodiments of the invention, the components can consist essentially of wear resistant ceramic materials. For example, the components can be bulk parts of a semiconductor material processing apparatus.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com