Pulsed laser beam machining method and apparatus for machining a wiring board at multiple locations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

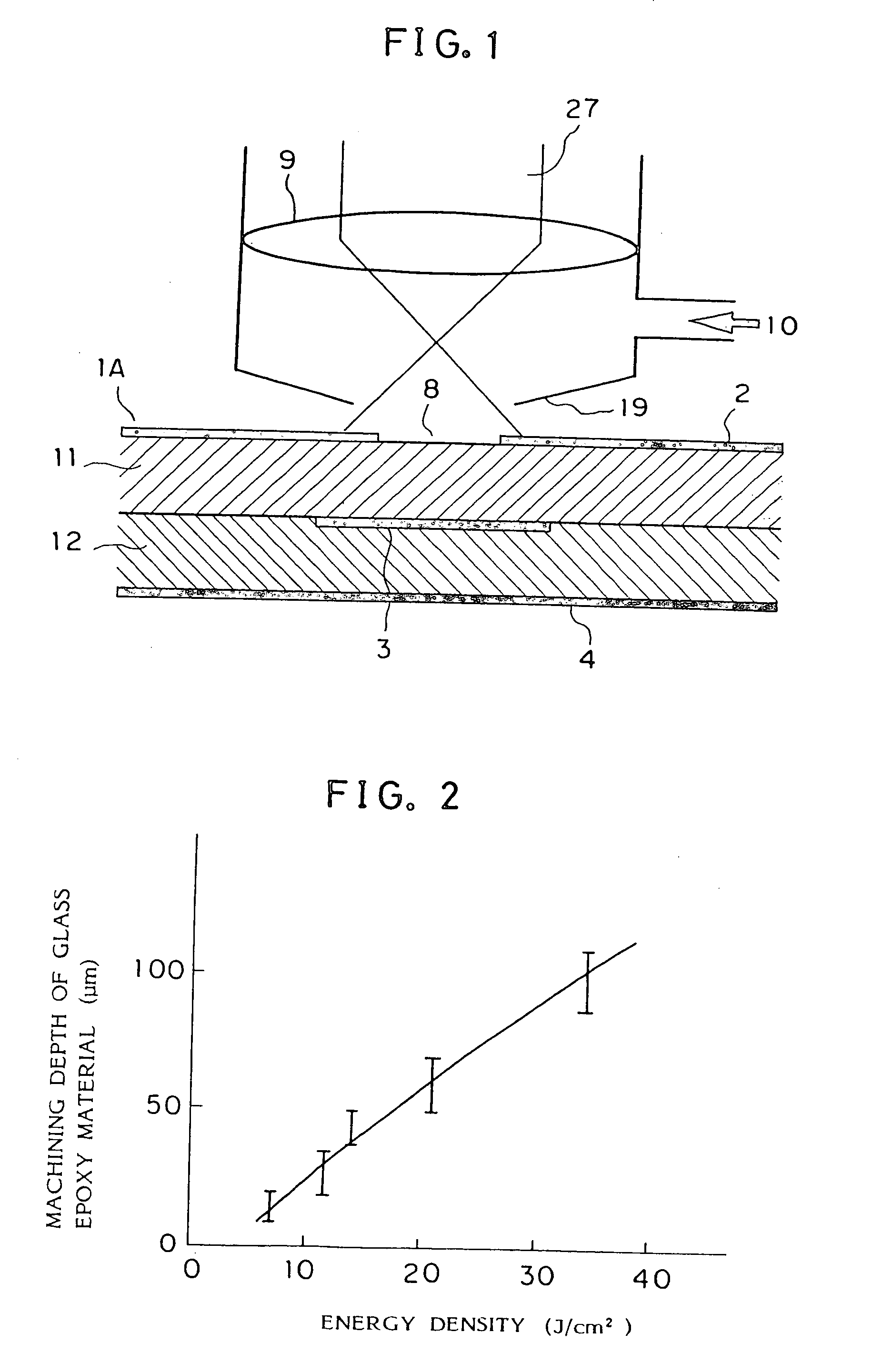

[0074]FIG. 1 is a typical diagram showing a laser beam machining method for a wiring board according to the embodiment 1 of the present invention. In the drawing, reference numeral 1A means a printed board (wiring board), 2, 3, and 4 are conductor layers (metallic layers) including copper foil, 8 is a copper foil removed portion formed in the top conductor layer 2 by etching, 9 is a ZnSe lens for convergence of a laser beam 27 radiated from a carbonic acid gas laser, and 10 is an assist gas for lens protection. Air is employed in the embodiment as the assist gas 10. Reference numerals 11 and 12 are insulating base materials, and 19 is a gas nozzle through which the assist gas 10 is ejected. Here, the copper foil removed portion 8 is formed in the conductor layer 2 at a portion corresponding to a machined portion of the insulating base material 11.

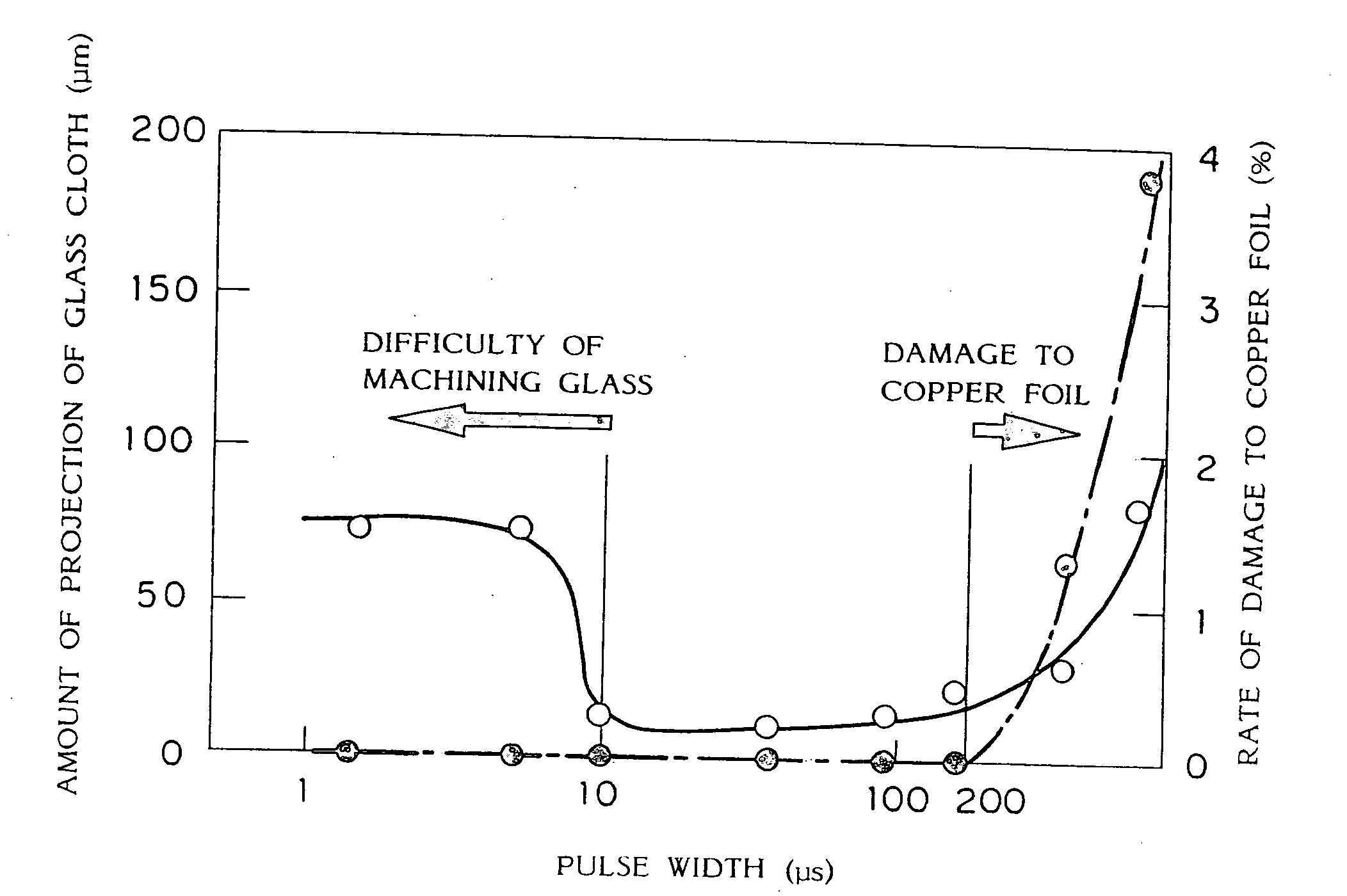

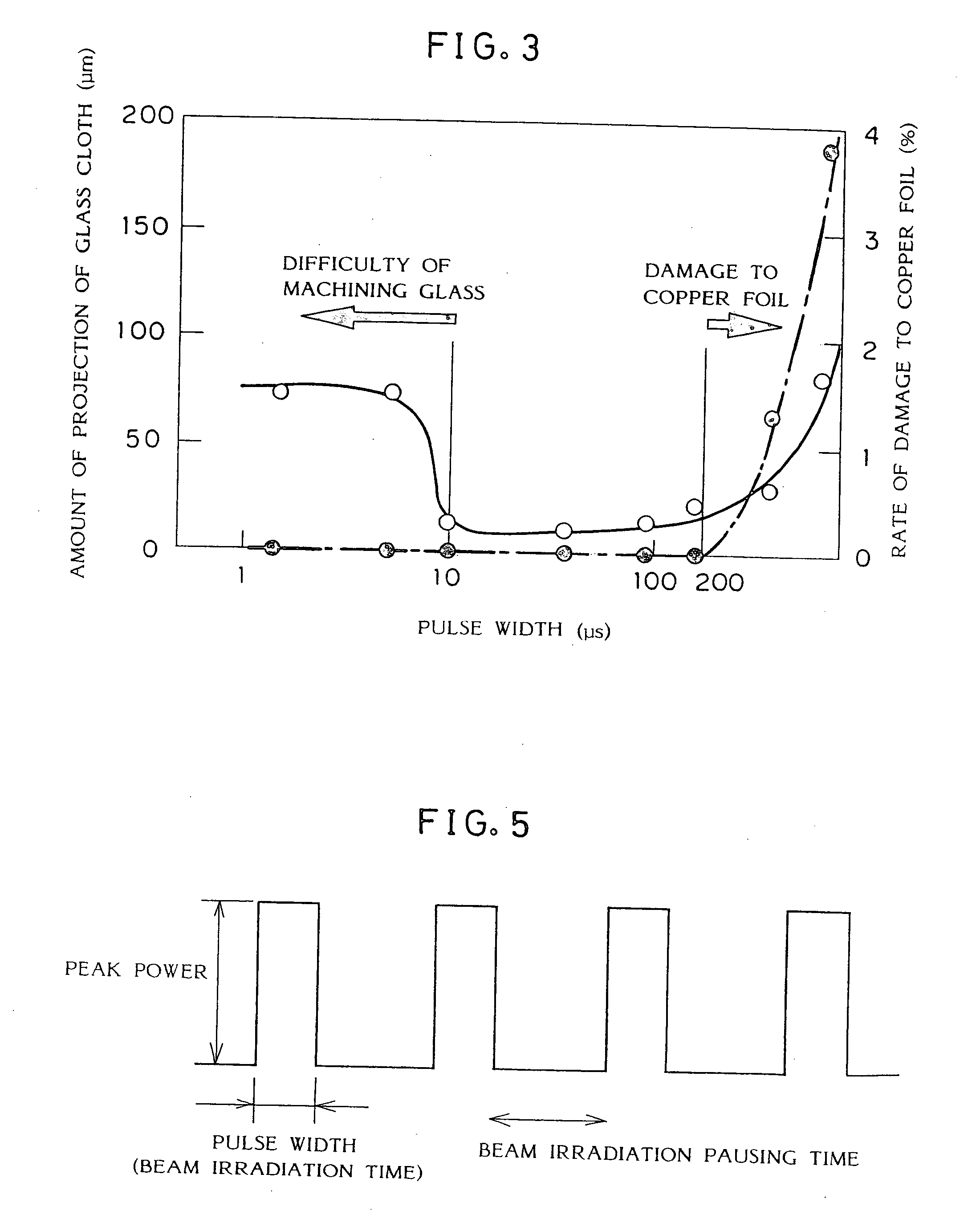

[0075] In the embodiment 1, a three-layer glass epoxy printed board (FR-4) with both sides coated with copper foil and a thickness of 200...

embodiment 2

[0082]FIG. 4 is a typical diagram showing a laser beam machining method for a wiring board according to the embodiment 2 of the present invention. In the drawing, the same reference numerals are used for component parts identical with those in FIG. 1, and descriptions thereof are omitted. Further, in FIG. 4, reference numeral 1B means a multi-layer printed board, 5 is a conductor layer, 6 is a conductor layer on a rear surface of the multi-layer printed board 1B, 7 is metal deposited on an inner surface of a through-hole 17, and 13 and 14 are insulating base materials. FIG. 5 is a waveform diagram showing an irradiation pattern of a laser beam 27 in the embodiment 2.

[0083] In the embodiment 2, a five-layer glass polyimide board with a thickness of 400 μm was used as the printed board 1B. In a top conductor layer 2 and a bottom conductor layer 6, copper foil had a thickness of 18 μm, and etching was made to form copper foil removed portions 8 with a diameter of 200 μm in the conduct...

embodiment 3

[0091]FIG. 8 is a waveform diagram showing an irradiation pattern of a laser beam in a laser beam machining method for a wiring board according to the embodiment 3 of the present invention. In the embodiment 3, as shown in FIG. 4 of the embodiment 2, a five-layer glass polyimide board with a thickness of 400 μm was used as a printed board 1B. In a top conductor layer 2 and a bottom conductor layer 6, copper foil had a thickness of 18 μm, and etching was made to form copper foil removed portions 8 with a diameter of 200 μm in the conductor layer 2 and the conductor layer 6 at positions corresponding to a conduction hole to be machined.

[0092] A description will now be given of the operation.

[0093] A laser beam 27 was emitted from a carbonic acid gas laser with a constant pulse width of 50 μs, and constant pulse energy of 280 mJ. Further, the laser beam 27 was condensed on the printed board 1B through a ZnSe lens 9 such that a laser beam diameter became 500 μm on a surface of the mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com