Wafer chuck having thermal plate with interleaved heating and cooling elements

a technology of thermal plates and chucks, which is applied in the field of wafer chucks, can solve the problems of chucks made of softer materials, prone to distort, and particularly difficult requirements, and achieves low electrical capacitance, high voltage or, and cost saving for users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

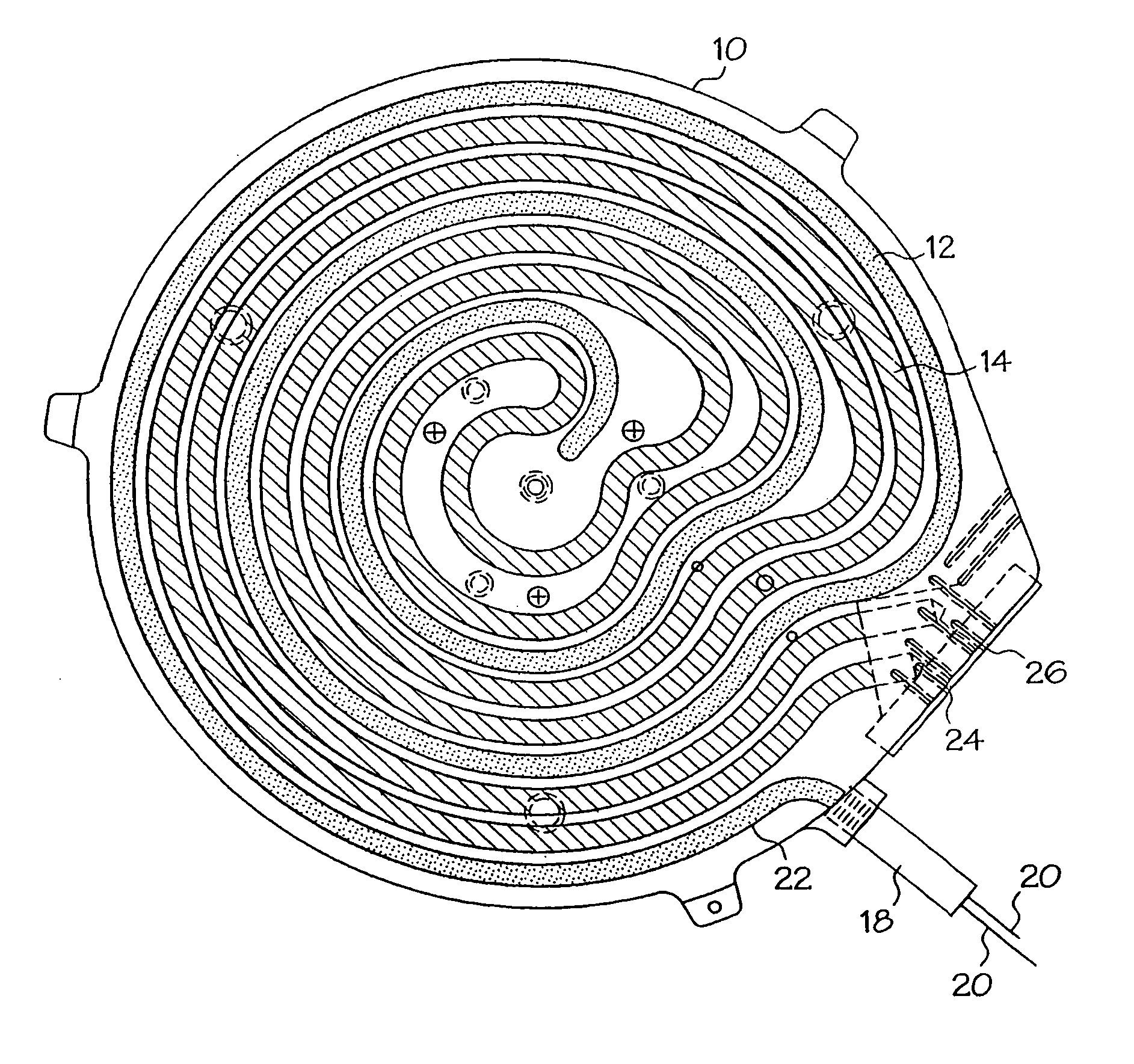

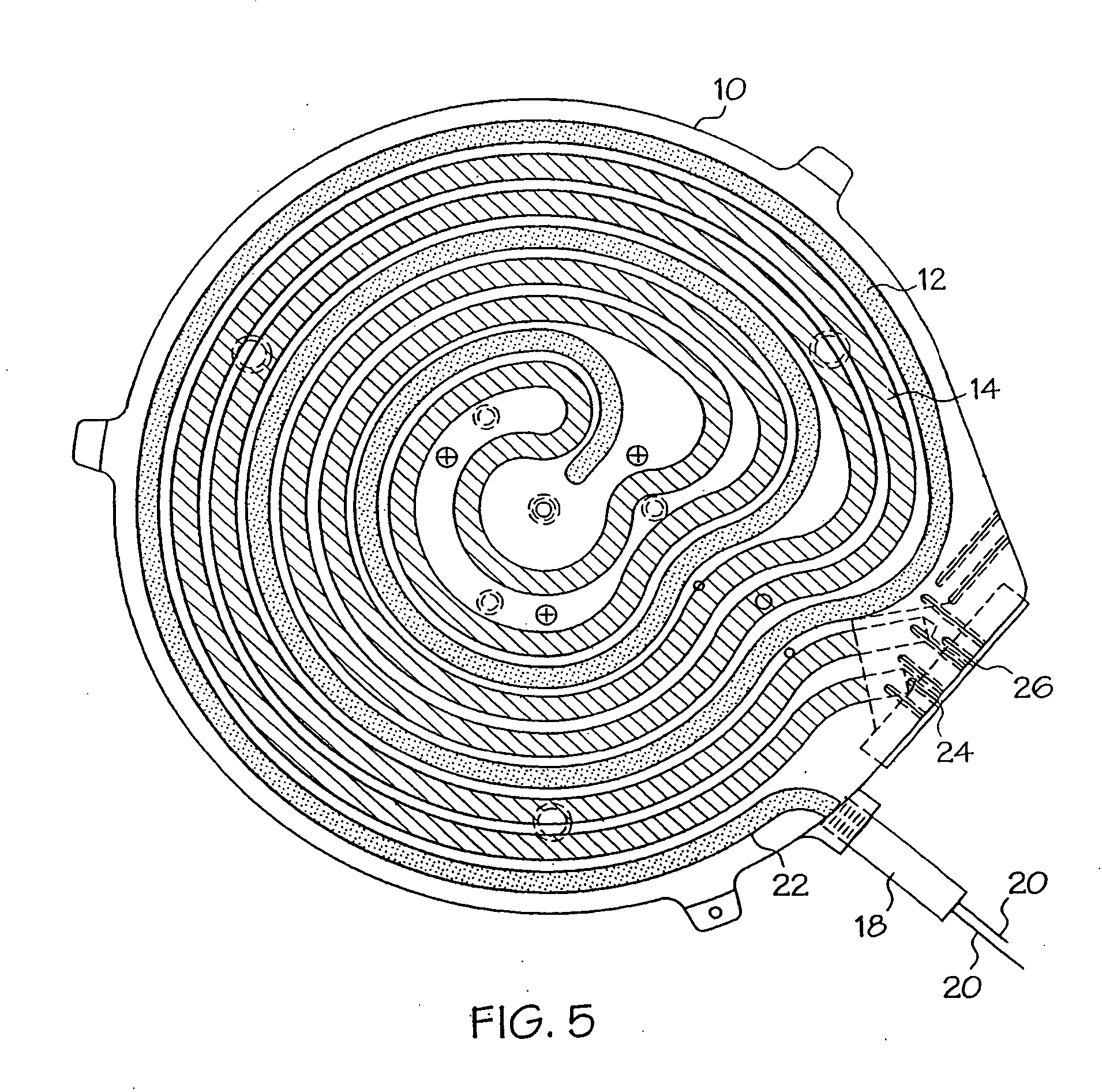

[0025] The present invention is directed to and is applicable in temperature-controlled workpiece chucks of the type described in, for example, U.S. Pat. No. 6,019,164, issued Feb. 1, 2000, entitled, “Workpiece Chuck,” assigned to Temptronic Corporation, and incorporated herein in its entirety by reference; U.S. Pat. No. 6,073,681, issued Jun. 13, 2000, entitled, “Workpiece Chuck,” assigned to Temptronic Corporation, and incorporated herein in its entirety by reference; and copending U.S. patent application Ser. No. 09 / 473,099, filed on Dec. 28, 1999, entitled, “Workpiece Chuck,” assigned to Temptronic Corporation, and incorporated herein in its entirety by reference.

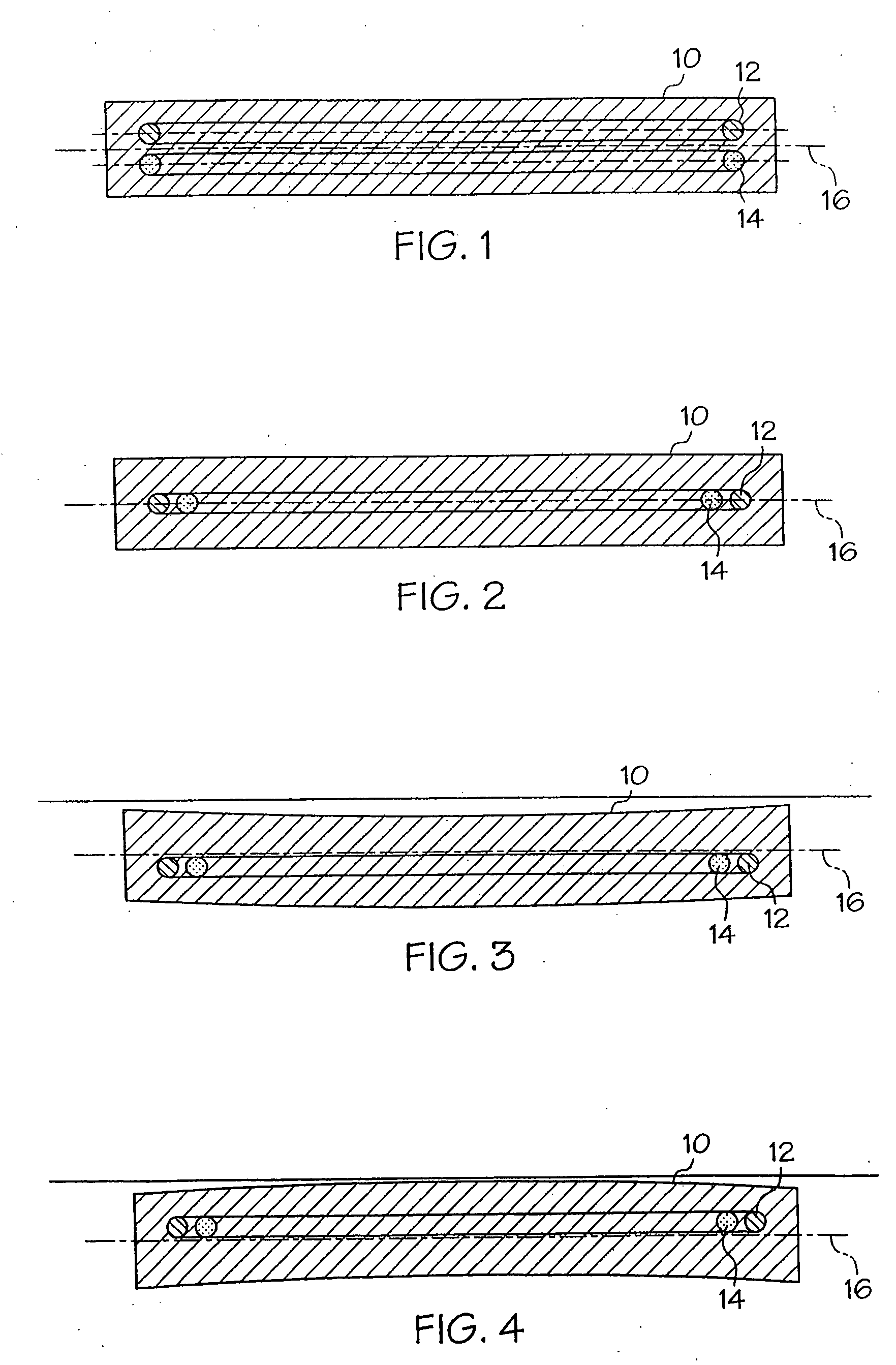

[0026] These chucks include a heater for heating the wafer under test and a heat sink for removing heat to cool the wafer. In accordance with the present invention, the heater and heat sink are formed in one integral assembly referred to herein as a thermal plate or thermal plate assembly. In one embodiment, the housin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isolation impedance | aaaaa | aaaaa |

| thermal distortion | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com