Laser irradiation apparatus and method for manufacturing semiconductor device

a laser irradiation and semiconductor technology, applied in the direction of instruments, recording signal processing, disposition/mounting of heads, etc., can solve the problems of low density of photon to time, low output power per unit time of continuous wave laser, and low density of pulsed laser. achieve the effect of increasing the throughput of laser irradiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment mode 1

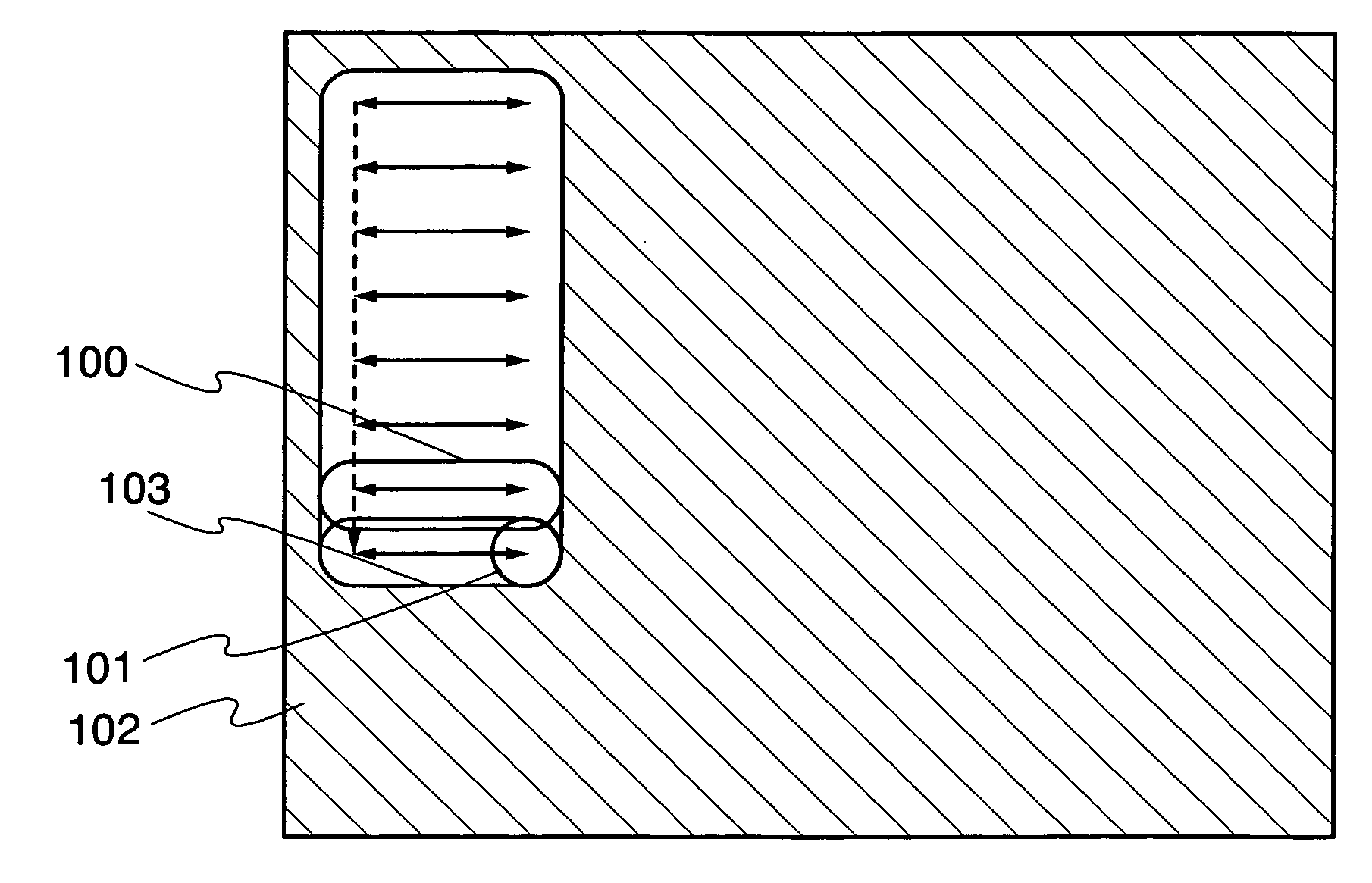

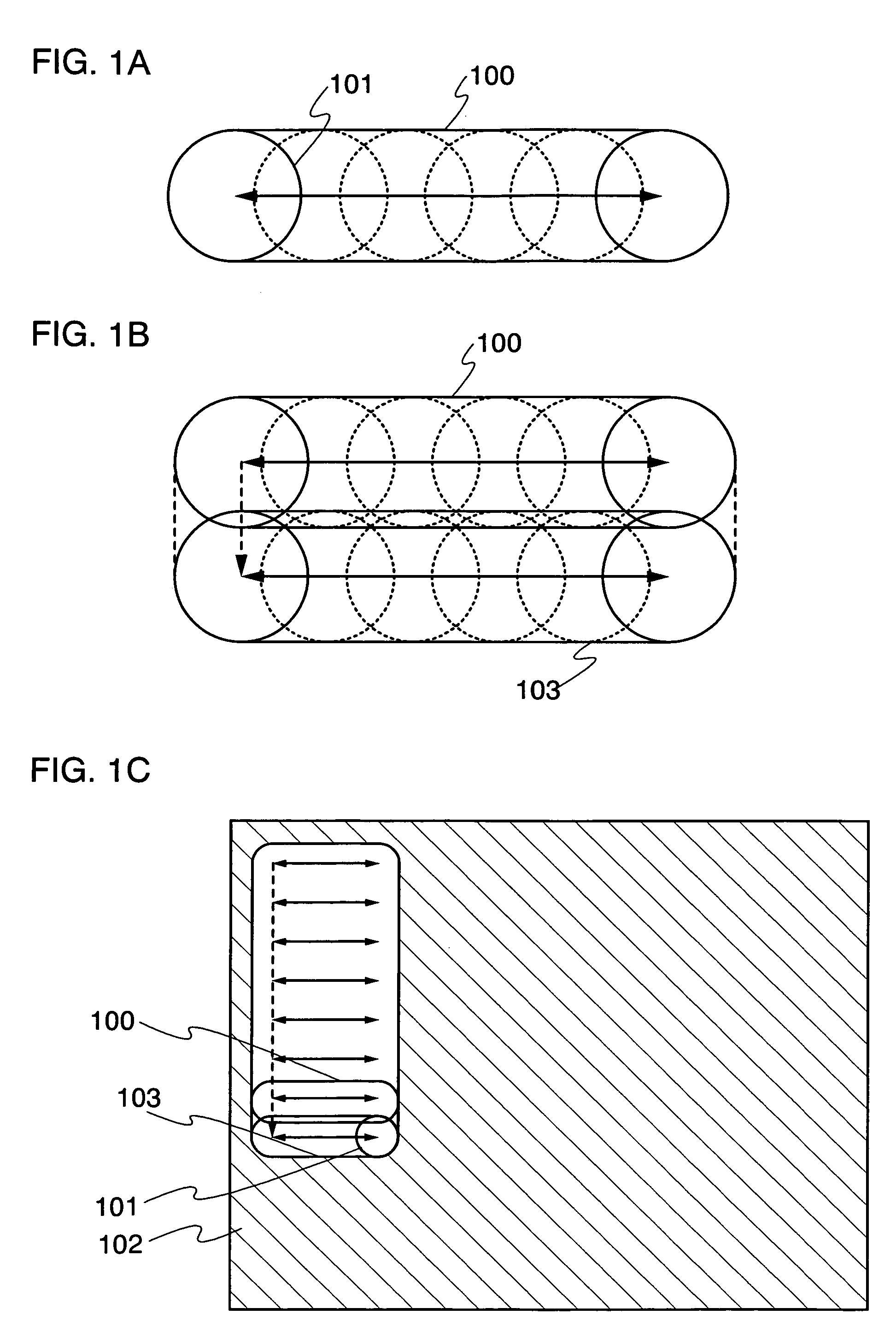

[0055] A step of forming a quasi-linear beam spot used in the present invention is described with reference to FIGS. 1A to 1C. As shown in FIG. 1A, a quasi-linear beam spot 100 is formed by scanning a beam spot 101 of the laser beam in a uniaxial direction or along a straight line as indicated by a solid-line arrow.

[0056] In FIG. 1A, the quasi-linear beam spot 100 is formed by scanning the beam spot 101 so as to move it back and forth. However, the present invention is not limited to this configuration, and the quasi-linear beam spot 100 may be formed by scanning the beam spot 101 in only one direction. Moreover, FIG. 1A illustrates the quasi-linear beam spot 100 formed in such a way that after the beam spot 101 is scanned from left to right, it is scanned from right to left again. However, the present invention is not limited to this configuration. In the present invention, the beam spot 101 may be scanned at least once in any one point in the quasi-linear beam spot 100.

[0057] In...

embodiment mode 2

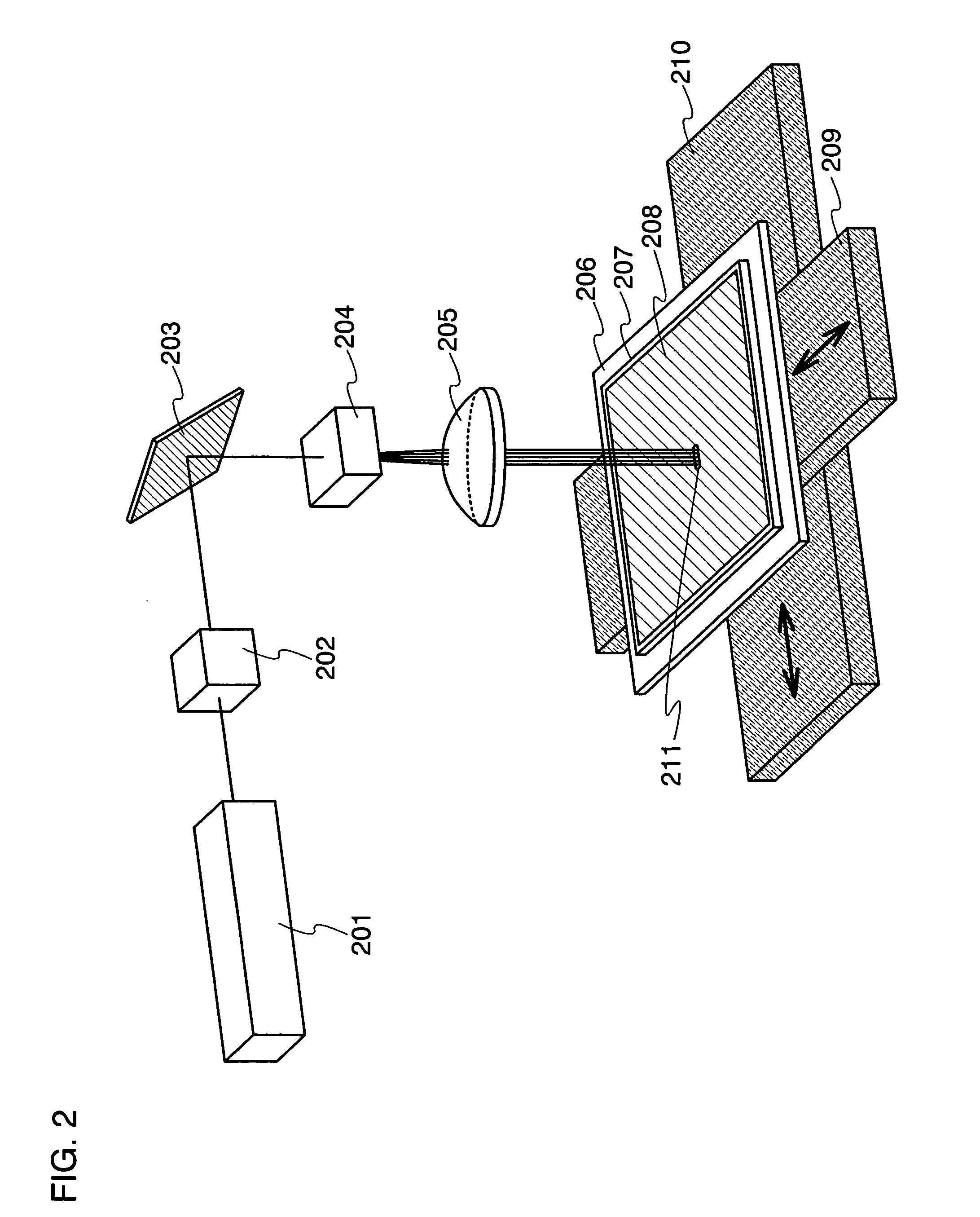

[0083] With reference to FIGS. 11A to 11C, this embodiment mode describes a scanning method of the laser beam which is different from the scanning method shown in the embodiment mode 1. Other parts of this embodiment mode except the scanning method of the laser beam are the same as those in the embodiment mode 1. The laser irradiation apparatus shown in FIG. 2 is used in this embodiment mode.

[0084] In FIGS. 11A to 11C, reference numerals 1101 and 1102 denote quasi-linear beam spots, reference numerals 1103 and 1104 denote beam spots, and a reference numeral 1105 denotes a semiconductor film, which is the irradiation object. By scanning the beam spot shown in FIGS. 11A to 11C, the quasi-linear beam spot is formed in the same way as the embodiment mode 1. The quasi-linear beam spot 1101 and the quasi-linear beam spot 1102, which is formed sequentially after the quasi-linear beam spot 1101, are scanned so that regions in these beam spots parallel to their major axes overlap each other...

embodiment mode 3

[0091] Another embodiment mode of the present invention is described.

[0092] First, the step of forming a quasi-linear beam spot used in the present invention is described with reference to FIGS. 4A to 4C. FIG. 4A shows a quasi-linear beam spot 300 formed by scanning a beam spot 301 of a laser beam in one direction or along a straight line as indicated by a solid-line arrow.

[0093] In FIG. 4A, unlike the embodiment mode 1, the beam spot 301 is scanned only in one direction to form the quasi-linear beam spot 300. The total time of laser irradiation can be homogenized in any one point within the quasi-linear beam spot 300 by scanning the beam spot 301 only in one direction as shown in FIG. 4A. Although FIG. 4A illustrates the beam spot 301 scanned from left to right, the present invention is not limited to this configuration. In the present invention, the beam spot 301 may be scanned at least once in any one point within the quasi-linear beam spot 300.

[0094] In the case of FIG. 4A, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com