Methods for removing suspended particles from soluble protein solutions

a technology of suspended particles and soluble protein, which is applied in the field of methods for removing suspended particles from soluble protein solutions, can solve the problems of high cost affecting the efficiency of large-scale centrifugation equipment, and affecting the quality of protein purification, so as to avoid the use of expensive capital equipment or chemicals, and improve the efficiency of large-scale centrifugation equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

6. EXAMPLE 1

Removing Suspended Particles from E. coli Lysate Containing SY161

[0055] 6.1. Lysis of E. coli Cells Expressing SY161

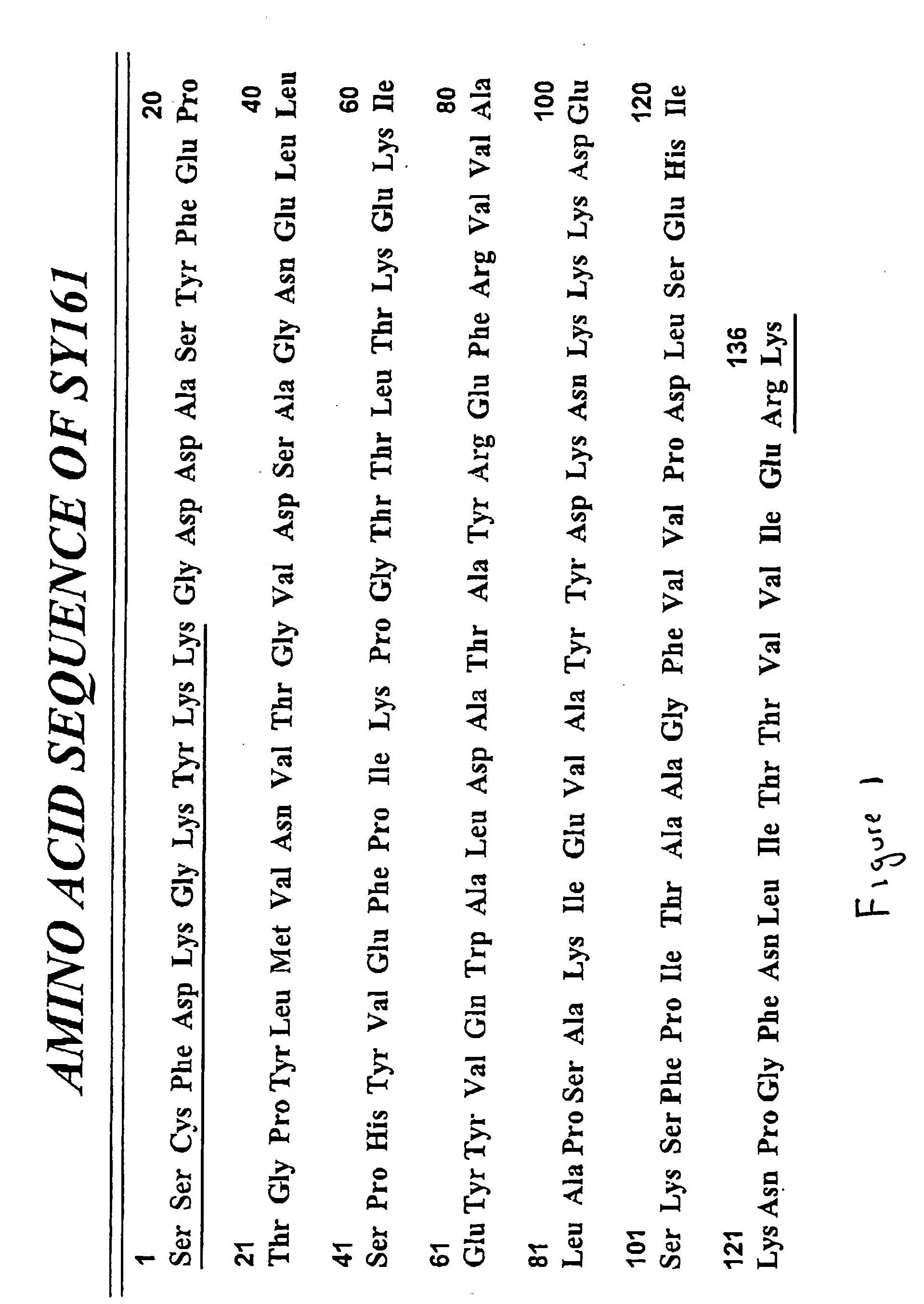

[0056] SY161 may be produced in E. coli strain TG1 transformed with plasmid pMc5-SY161-S3C. This clone represents 13 mutations from the original Staphylokinase gene subcloned from Staphylococcus aureus.

[0057] The E. coli cells expressing SY161 were harvested by centrifugation and stored at −70° C. prior to use. The frozen cell paste was broken into pieces and suspended in about 7.0 volumes (weight / volume) of lysate buffer (50 mM sodium phosphate, pH 9.5 containing 5 mM EDTA) using an overhead mixer set at between about 500 RPM to about 1000 RPM. Mixing was continued until the cell paste was completely suspended in the lysate buffer. A microfluidizer unit was assembled by connecting the required air pressure lines, coolant lines and hoses. The microfluidizer was then purged with lysate buffer and the pressure was adjusted to between about 13,000 psi to ab...

example 2

7. EXAMPLE 2

Removing Suspended Particles from E. coli Lysate

[0065] 7.1 Lysis of E. coli cells that do not Express a Heterologous Protein

[0066]E. coli null cells (E. coli TGI, pMc5-8 (Δ clone)) for expression of SY161 were harvested by centrifugation and stored at −70° C. prior to use. The frozen cell paste was suspended in about 7.0 volumes (weight / volume) of lysate buffer (50 mM sodium phosphate buffer, pH 9.5, containing 5 mM EDTA). The frozen cell paste was stirred for about 0.5 hour with a Silverson Lab Mixer Emulsifier (Model L4R) at about 3,000 rpm to resuspend the cells. A microfluidizer (Model 110Y) was connected to compressed air and the cooling chamber was filled with ice. The homogenizer was purged with lysate buffer and the pressure was adjusted to between about 13,000 psi to about 14,000 psi. The suspended cells were fed into a homogenizer and lysed under the operational pressure of between about 13,000 psi to about 14,000 psi. The once-lysed cell suspension was colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com