Systems and methods for producing aqueous solutions and gases having disinfecting properties and substantially eliminating impurities

a technology of aqueous solutions and gases, which is applied in the direction of biocide, water/sewage treatment by oxidation, liquid transfer devices, etc., can solve the problems of high generation equipment, high production costs, and inability to produce chlorine dioxide vapor or liquid, etc., to facilitate the passage of moisture into the device and increase the moisture transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

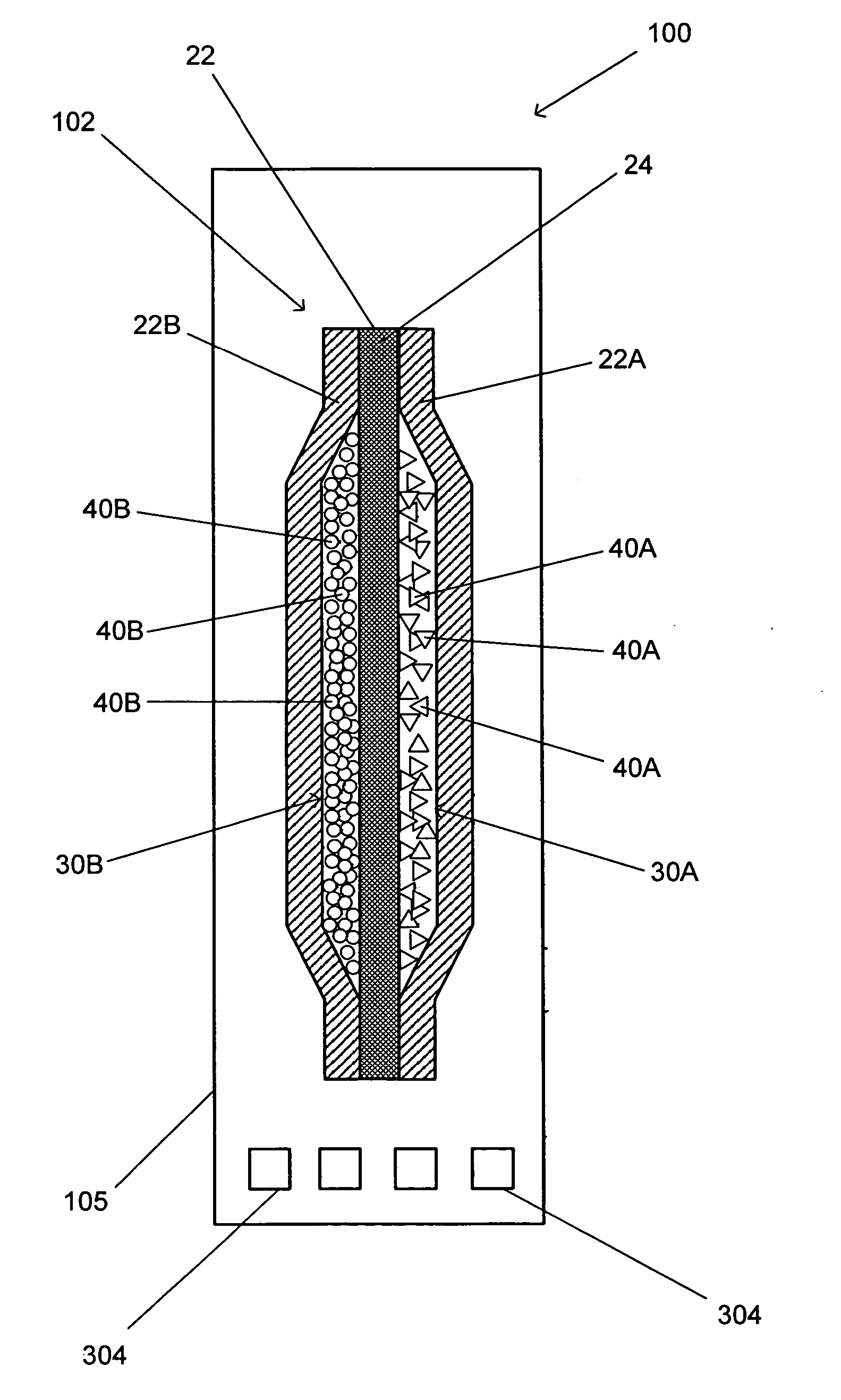

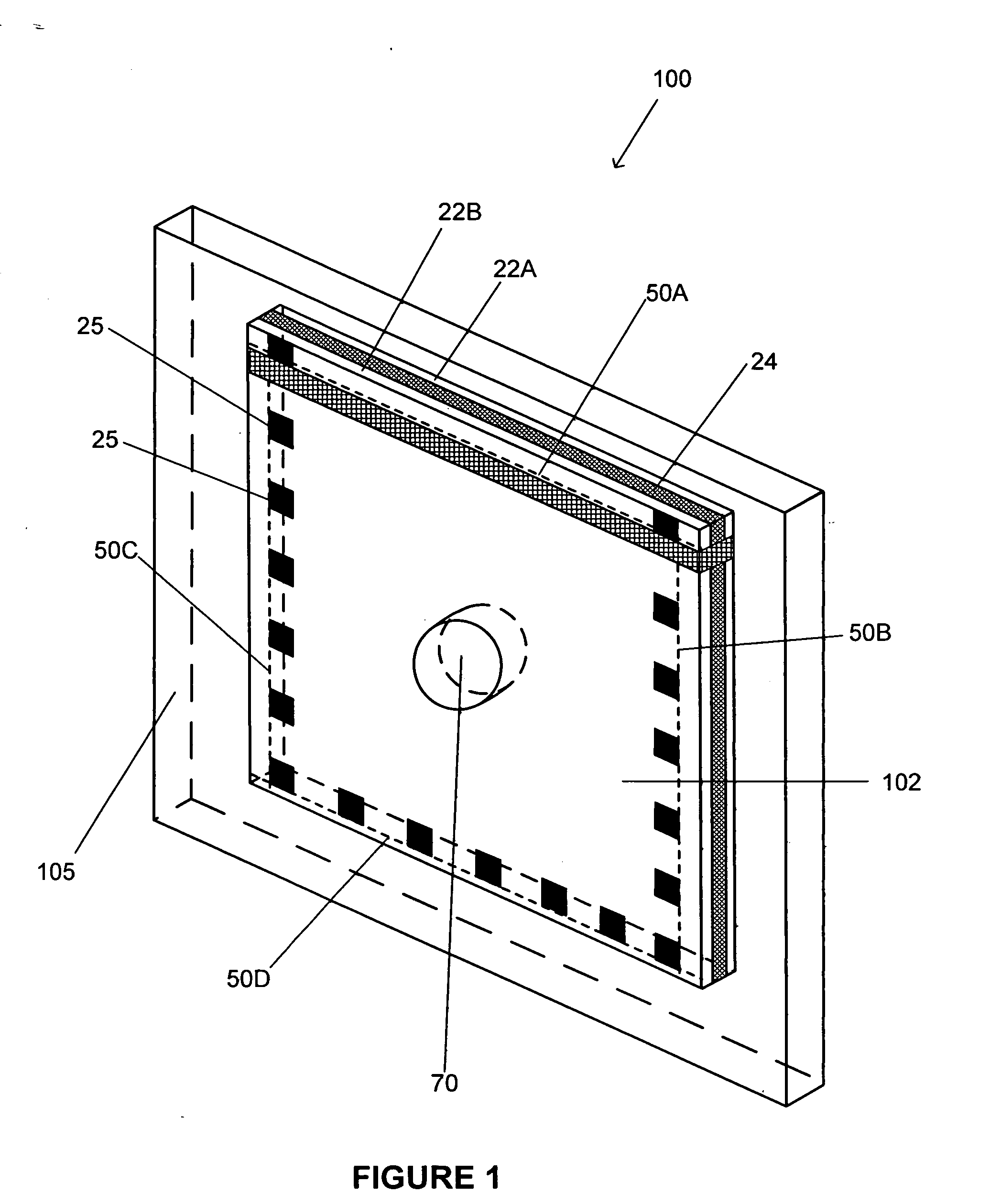

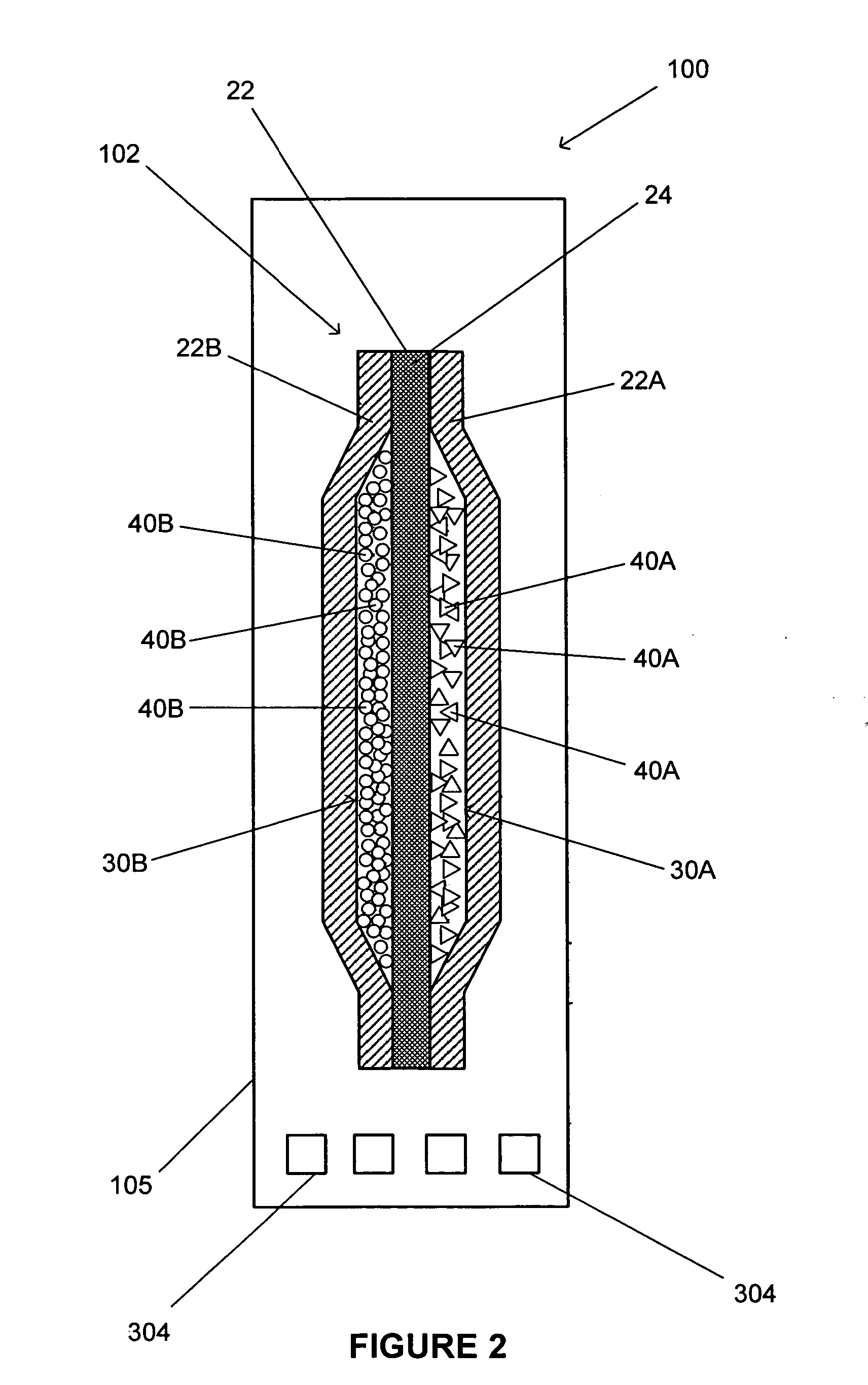

Image

Examples

example 1

[0111] Two layers of a microporous, hydrophobic non-woven polyethylene sheet material (Tyvek® sold by E.I. Du Pont de Nemours & Co.—type 1073B) was intermittently heat sealed to a hydrophilic material consisting of non-woven natural and synthetic fibers (Sontara® sold by Dupont). The Sontara® was placed between the two layers of Tyvek® and the bottom and sides were sealed forming a pouch divided in two, creating two compartments. The pouch measured 2.5 inches by 2.5 inches. One compartment of the pouch was filled with 0.4 g technical grade sodium chlorite of 80% purity and the other compartment was filled with 0.4 g sodium bisulfate. The pouch was placed in 5 gallons of tap water at 20° C. The absorbance of the solution was measured with a spectrophotometer at a wavelength of 360 nm and then converted to an mg / l concentration of chlorine dioxide.

TABLE 1TimeConcentration 0 min. 0 mg / l15 min.2.5 mg / l30 min.3.5 mg / l45 min.3.8 mg / l60 min.3.8 mg / l

This final concentration of 3.8 mg / l ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com