Apparatus for measuring a mechanical quantity

a mechanical quantity and apparatus technology, applied in the direction of force measurement using piezo-resistive materials, instruments, reradiation, etc., can solve the problems of large measuring errors, small noise detection accuracy, and large noise of strain sensors, so as to reduce the power consumption of sensors, compensate for small changes in mechanical quantity sensors, and reduce noise. the effect of the sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of this invention will be disclosed. A strain measuring system that operates on an electricity supplied by electromagnetic induction or microwaves can be formed on one and the same silicon substrate.

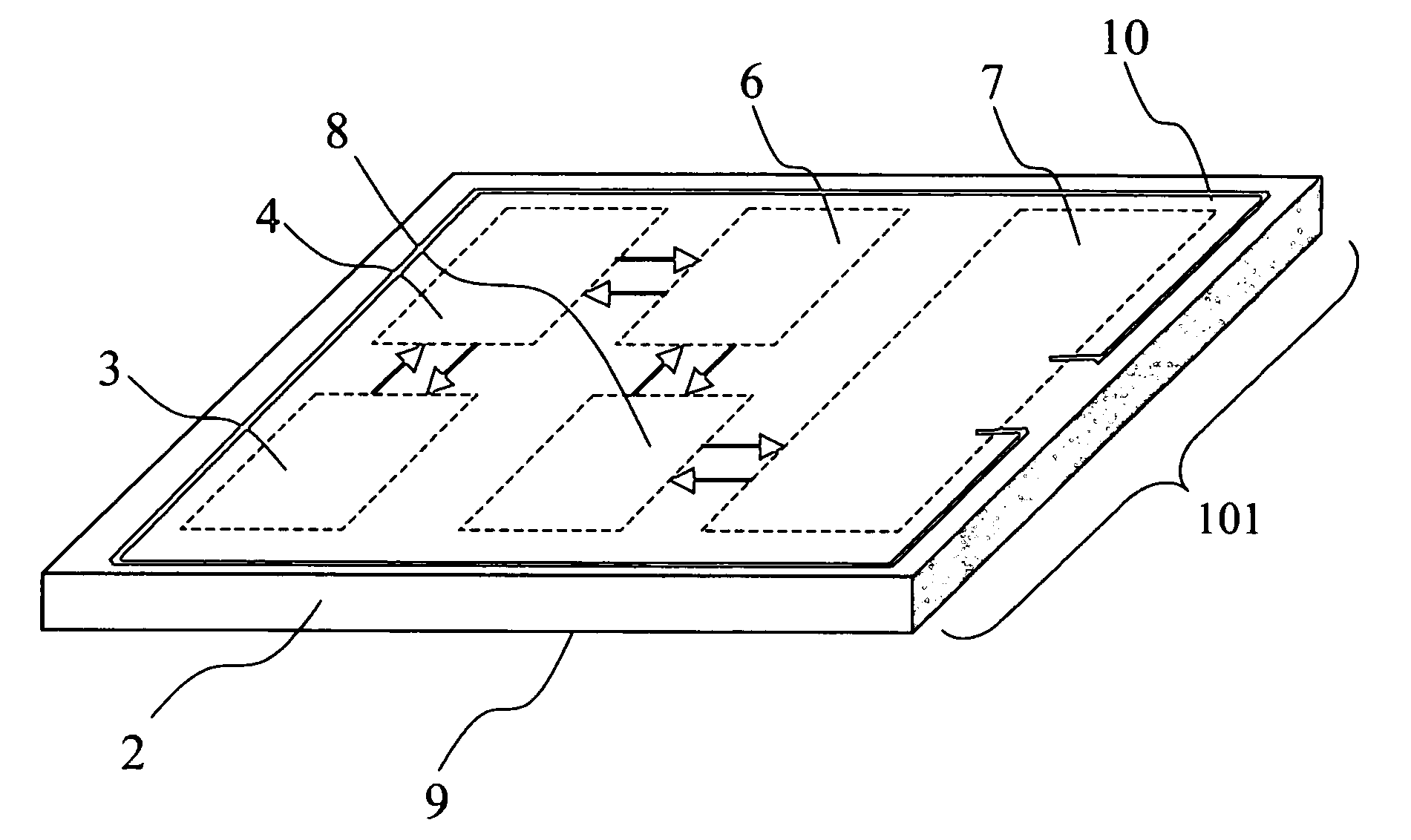

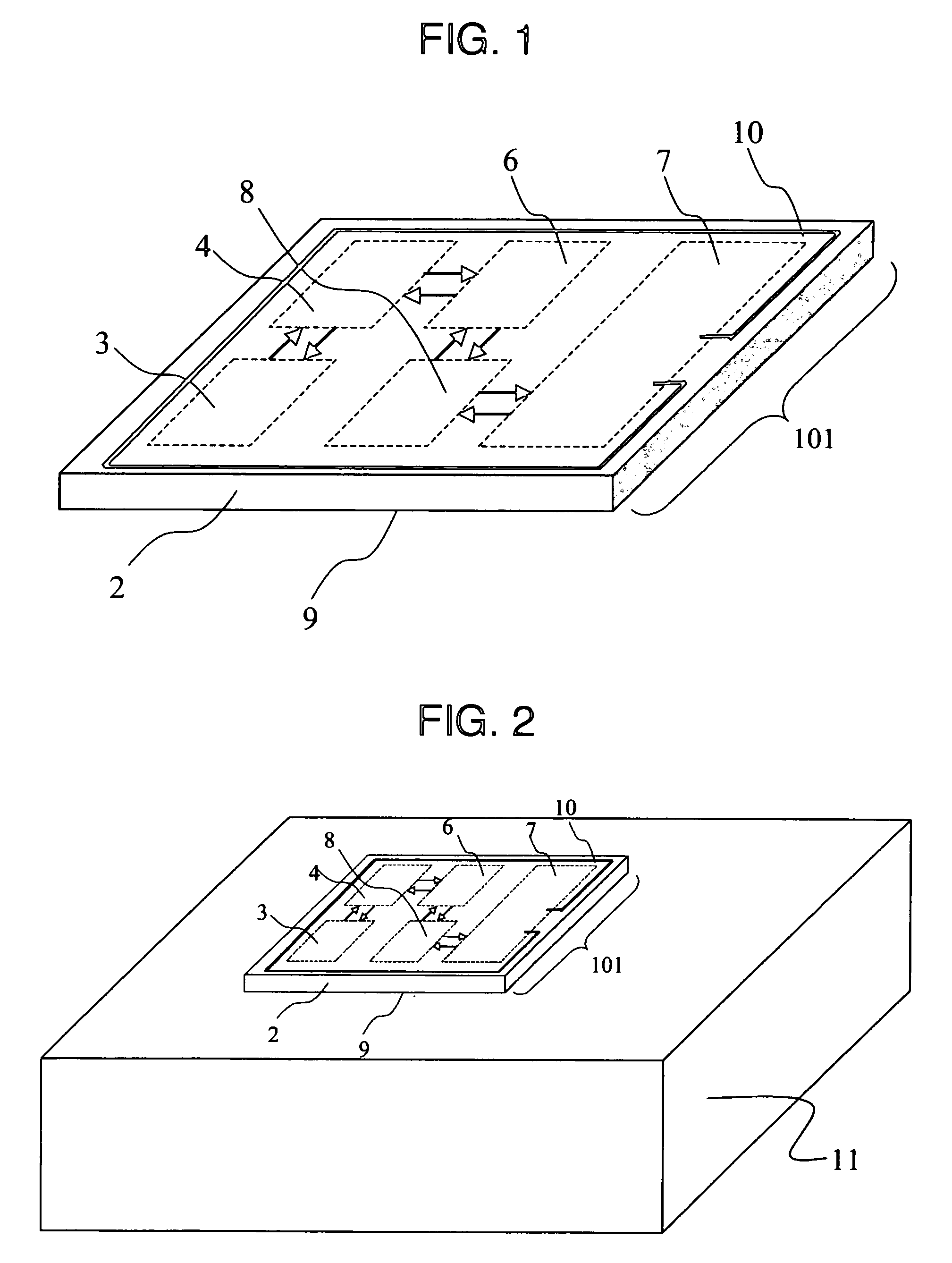

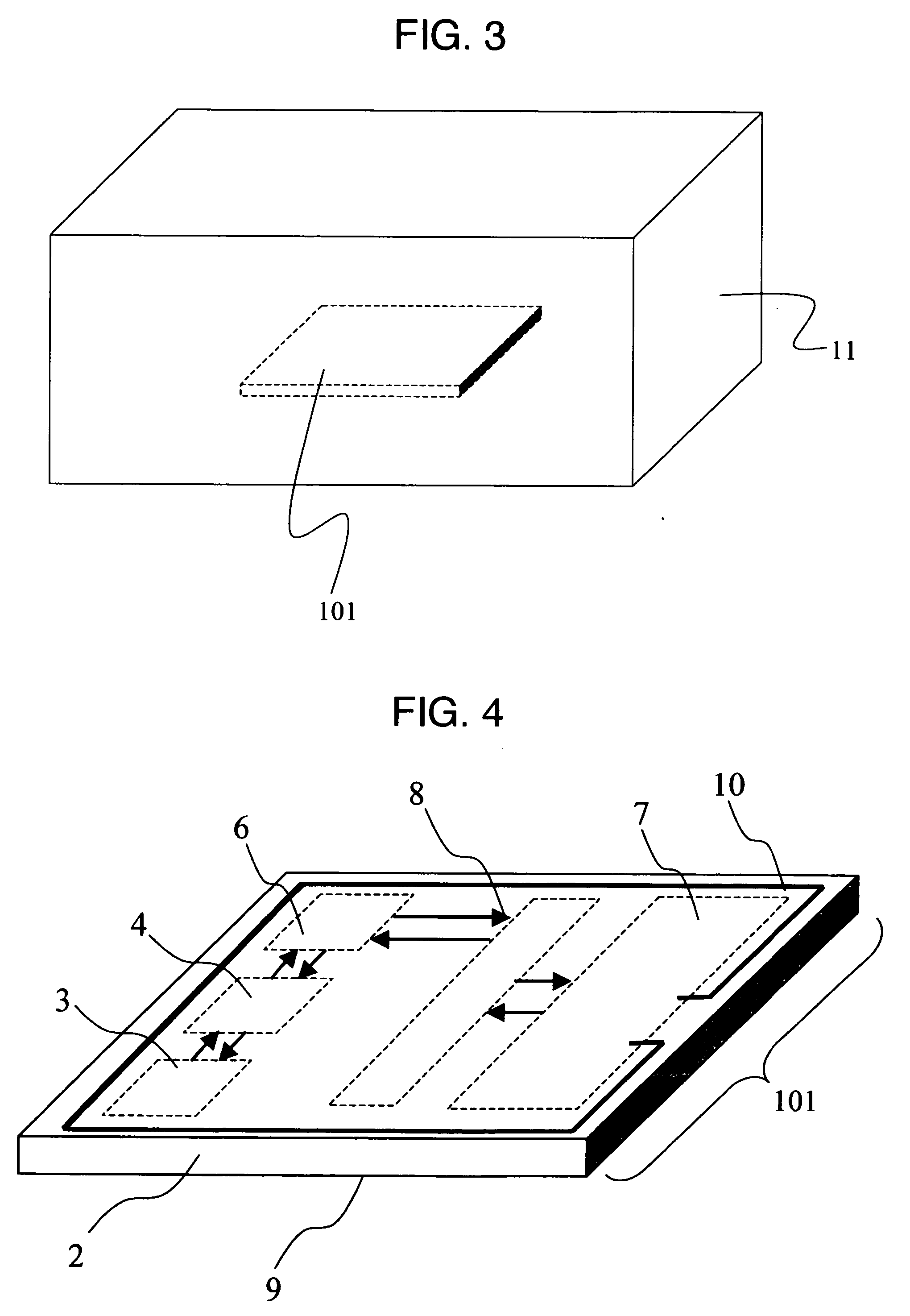

[0058] Embodiments of this invention will be described by referring to FIG. 1 through FIG. 10. FIG. 1 shows a mechanical quantity measuring apparatus 1 as a first embodiment of this invention. This embodiment is a mechanical quantity measuring apparatus having formed on one and the same single crystal silicon substrate 2 at least a strain sensor 3 utilizing a piezoresistive effect, a strain sensor amplifier group 4, an analog / digital converter 6, a rectification / detection / modulation-demodulation circuit 7, a communication control unit 8, a bonding surface 9, and an antenna 10. In the following description the silicon substrate 2 and a group of thin films formed on the silicon substrate 2 are together called a chip 101. Although the antenna 10 may be formed in large si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com