Antireflection film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

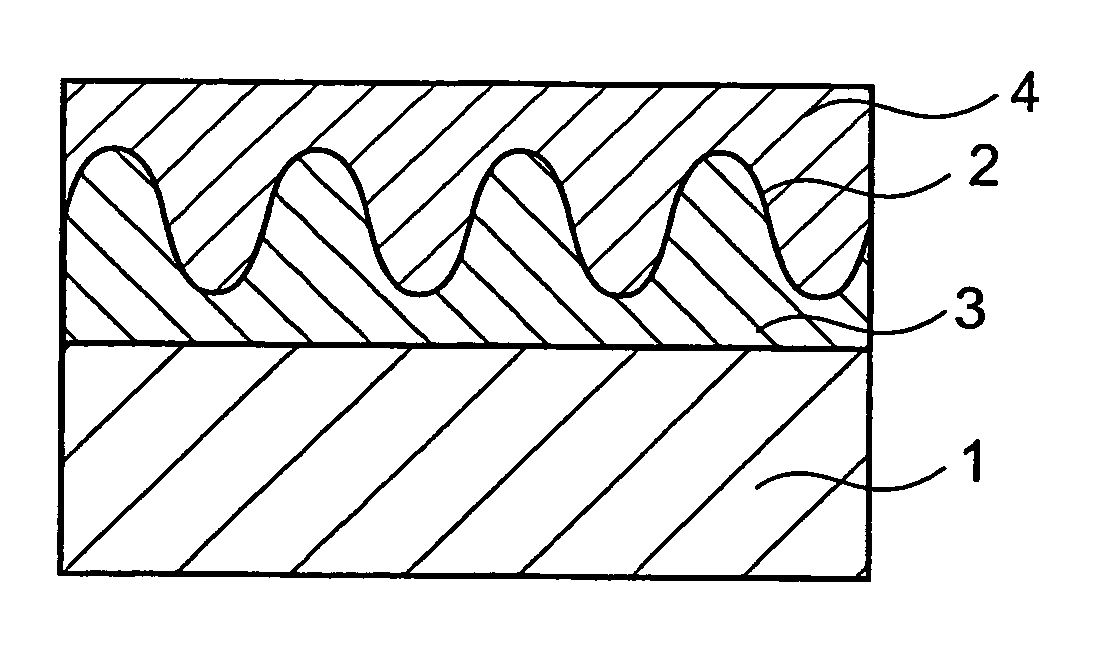

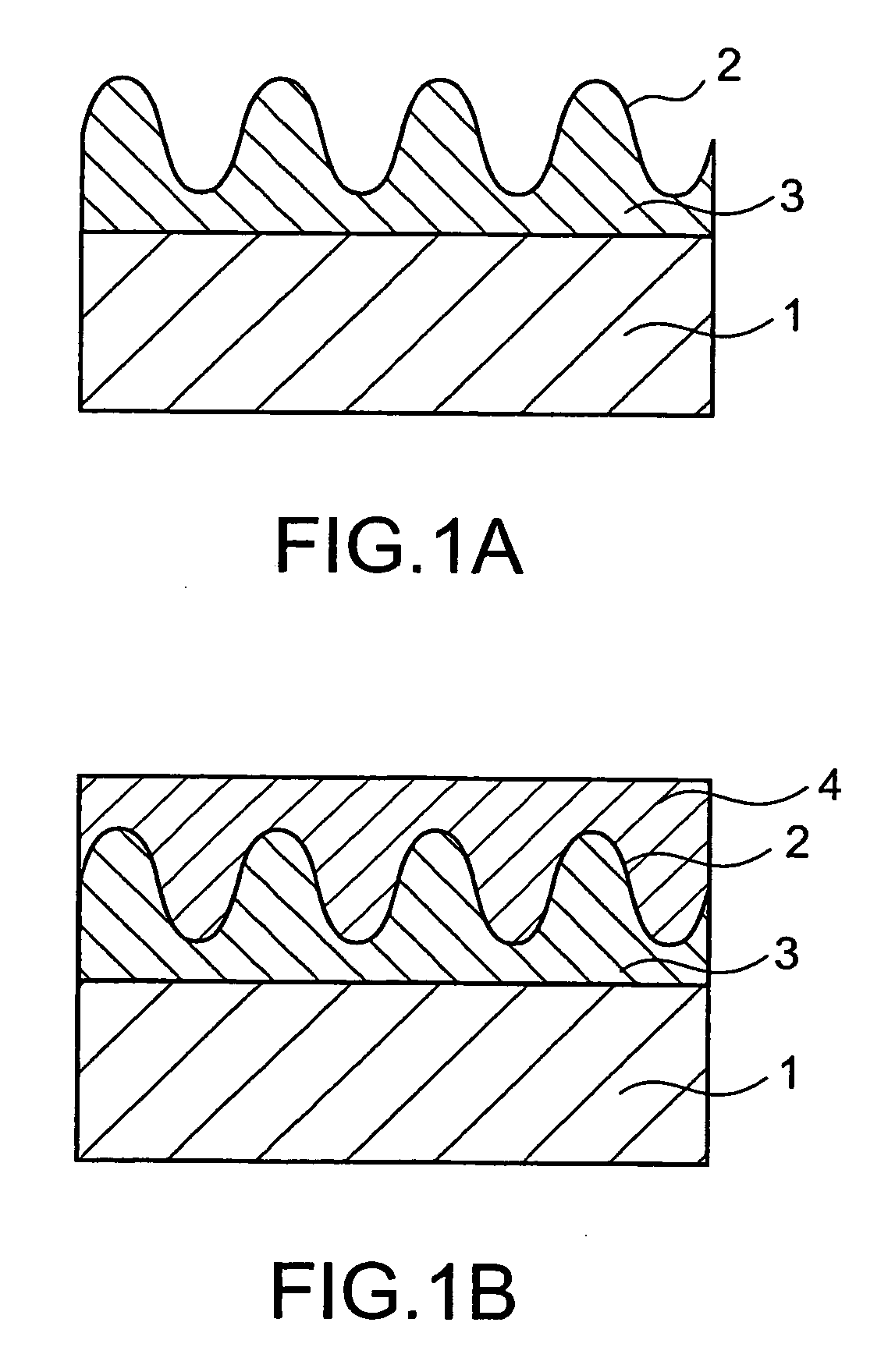

[0112] A photosensitive resin was coated by a spinner onto a glass substrate with a diameter of 76 mm to prepare a photosensitive material. The photosensitive material was exposed by means of a laser interference exposure system using an argon laser (wavelength 351 nm) at an angle of incidence of 40 degrees from three directions. After the exposure, solvent development was carried out to prepare an original mold having fine concaves and convexes arranged lengthwise and breadthwise on a cured product of the photosensitive resin.

[0113] The pitch of concaves and convexes on the original mold was 280 nm, and the difference in level between concaves and convexes was 200 to 250 nm.

[0114] The surface of the original mold was electrolessly plated, followed by plating with nickel to prepare a 100 μm-thick duplicate mold. This procedure was repeated to prepare duplicate molds. A large mold having a width of 500 mm and a length of 980 mm was prepared by multi-side attachment of the duplicate...

example 2

[0118] A fluororesin-based surface coating liquid was coated by dipping on fine concaves and convexes on the cured film in the antireflection film prepared in Example 1. The coating was then dried to prepare an antireflection film.

[0119] Fingerprints were applied onto the surface of this antireflection film, and the surface of the antireflection film was then wiped with cotton. As a result, the fingerprints could be wiped off.

example 3

[0120] An antireflection film was prepared in the same manner as in Example 1, except that a coating composition (an ATO ultrafine particles coating composition, manufactured by Shinto Paint Co., Ltd.) containing ultrafine particles of ATO (antimony-dopedindium tin oxide) was coated onto the easy-adhesion polyester resin film as used in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com