AlGaN substrate and production method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

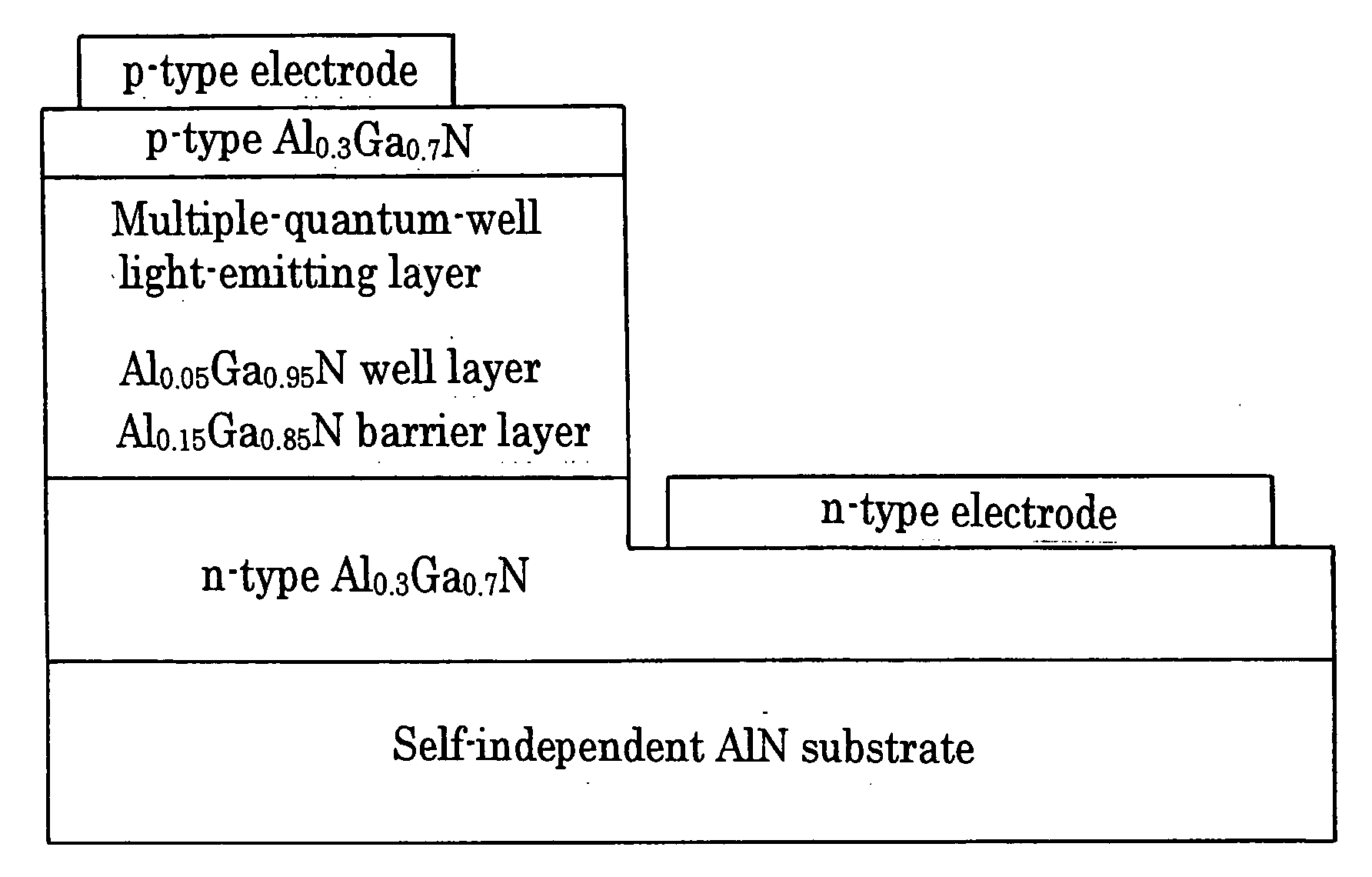

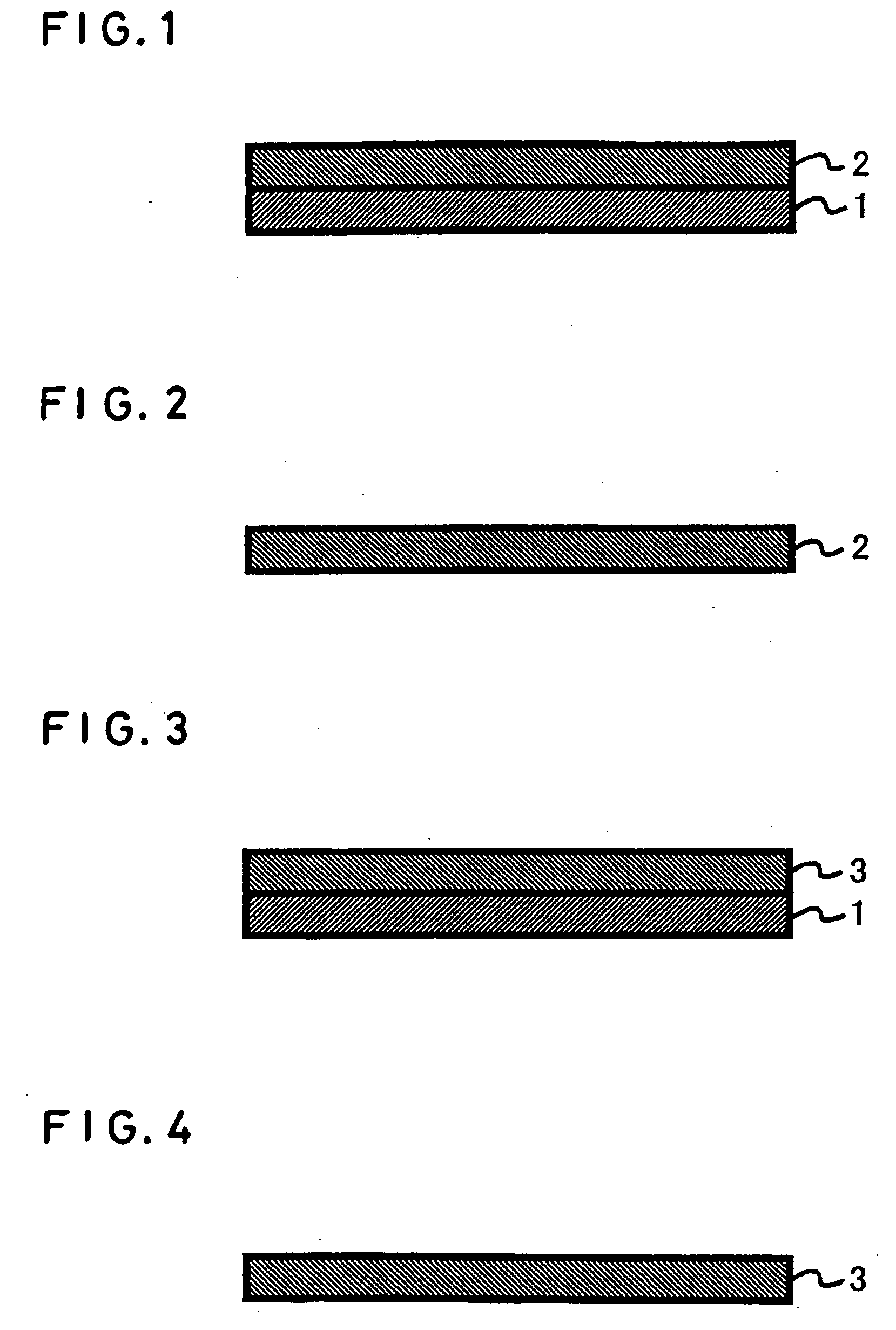

[0045]FIG. 1 is a cross section typically showing a structure having an layer of AlN deposited on a sapphire substrate, and FIG. 2 is a cross section showing the AlN layer having exfoliated from the sapphire substrate.

[0046] A structure having an AlN layer deposited on a sapphire substrate was produced in accordance with the following procedure using the ordinary pressure-reduced MOCVD means. First, a (0001-sapphire substrate 1 was placed on a susceptor having highly pure graphite (for a semiconductor) coated with tantalum carbide (TaC). The resultant susceptor was set in position within a vapor phase growth reaction furnace formed of stainless steel and highly pure graphite (for a semiconductor) coated with thermally decomposed carbon (PYROCARB), and nitrogen gas was circulated within the reaction furnace to purge the inside of the reaction furnace.

[0047] Once the inside of the vapor phase growth reaction furnace was evacuated, hydrogen and nitrogen were circulated within the rea...

example 2

[0053] In place of the AlN film of the stacked structure fabricated in Example 1, an AlxGa1-xN (01Ga1-xN (0xGa1-xN (0<x≦1) film having exfoliated from the sapphire substrate.

[0054] The fabrication method was the same as that in Example 1 while TMA and TMG were supplied as the raw materials for four hours to fabricate an AlxGa1-xN (0

[0055] The AlxGa1-xN (03) gas was supplied into the vapor growth reaction furnace so that a V / III ratio might be 100.

[0056] The wafer taken out was partially divided to enable the divided cross section to be observed. The cross section was observed with an SEM to find that an AlN film of about 80 μm was deposited. An X-ray diffraction was used to find that the half-value widths of the diffraction peaks at the (0002) and (10-10) planes were 500 seconds and 1000 seconds, respectively, and confirm that the AlN film was a single crystal. In addition, it was confirmed from the diffrac...

example 3

[0058] An AlN substrate was fabricated by following the procedure in Example 1 while the growth temperature in the AlN stacked structure fabricated in Example 1 was set to be 1150° C.

[0059] As a result, the half-value width of the diffraction peak at the (0002) plane by the X-ray diffraction was 2000 seconds or more. Thus, the AlN substrate was lower in crystallinity than that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com