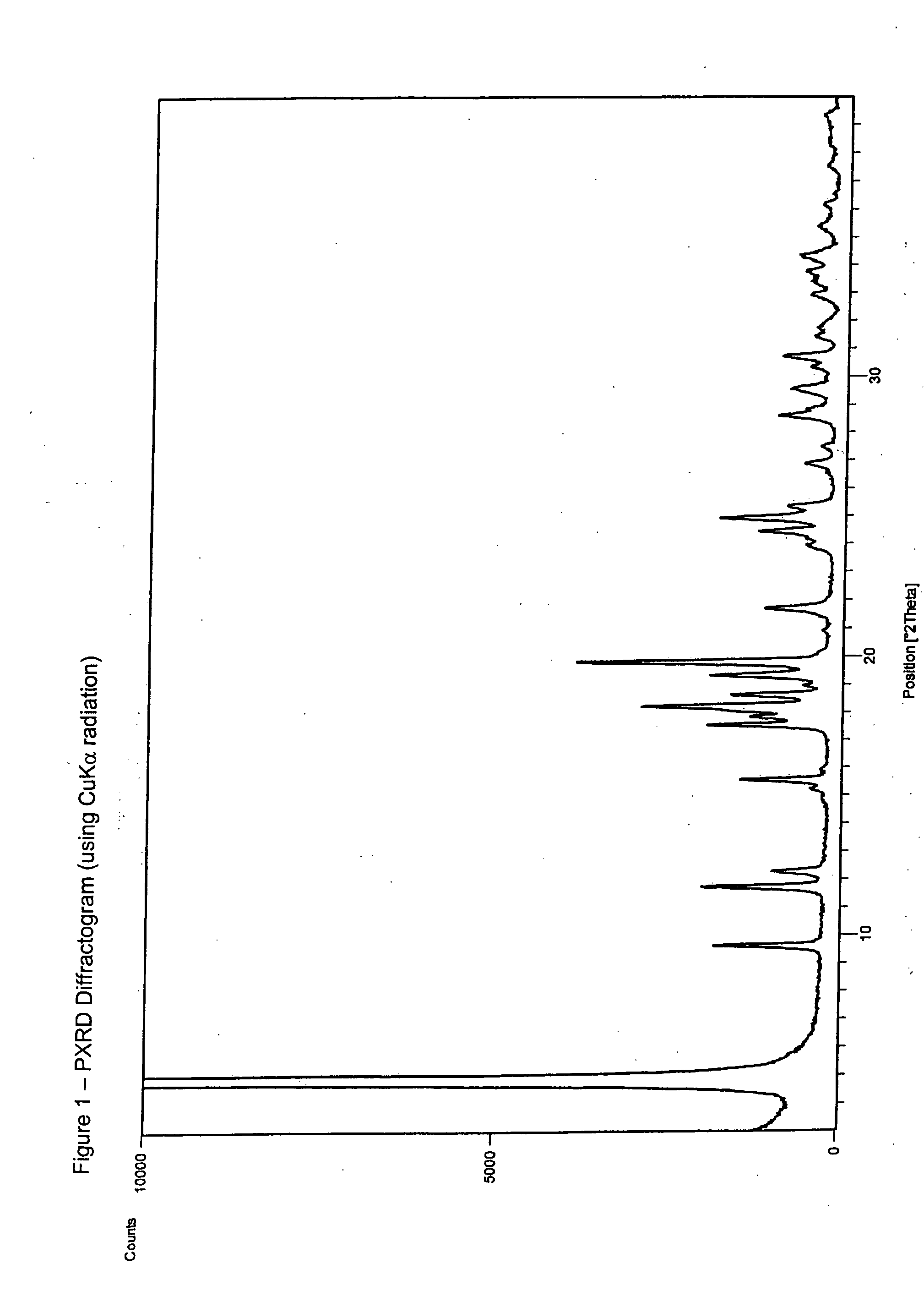

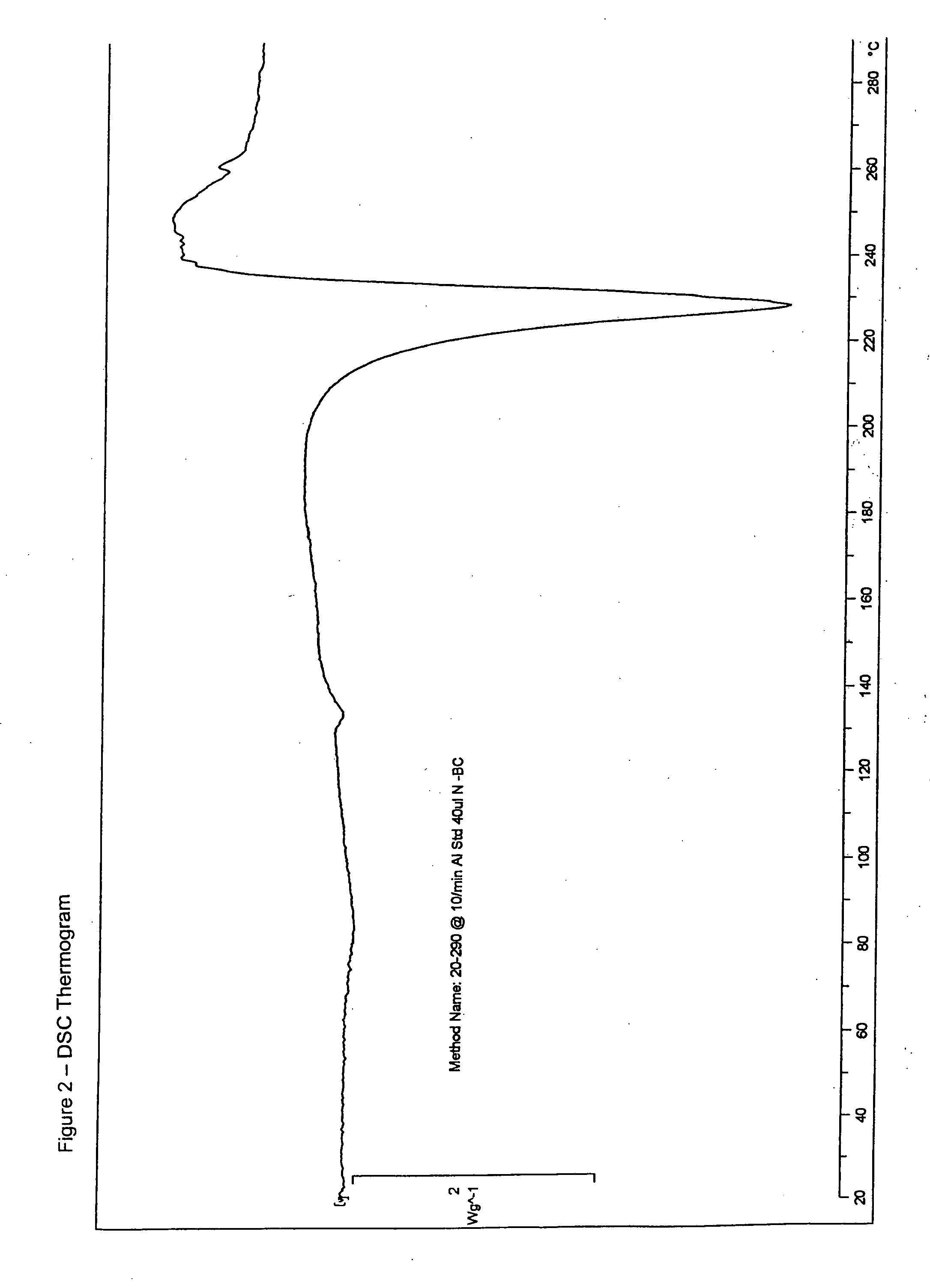

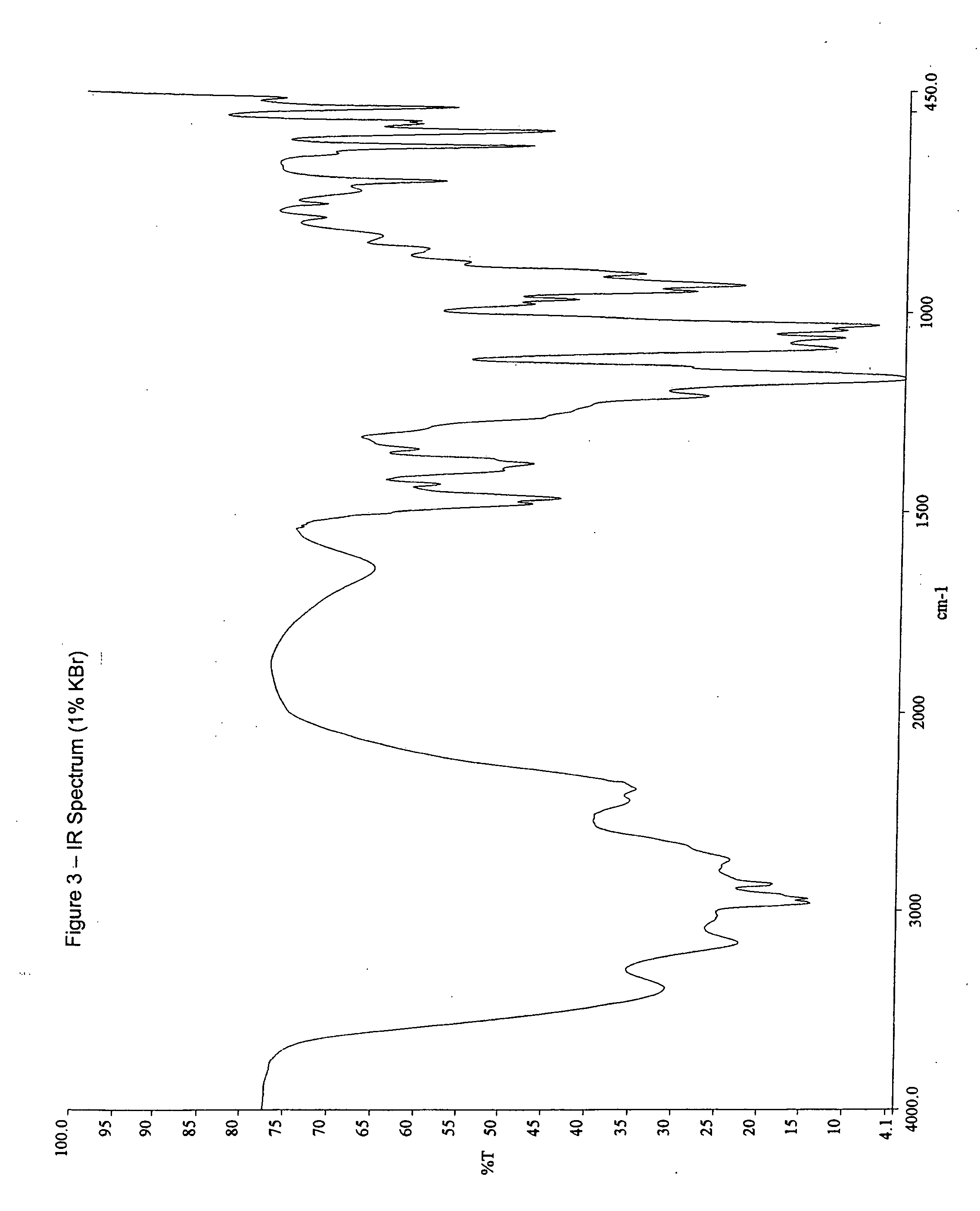

Ibandronate sodium propylene glycol solvate and processes for the preparation thereof

a technology of ibandronate and propylene glycol, which is applied in the field of new solvated form of ibandronate sodium, can solve the problems of toxic types of solvating agents, and achieve the effect of easy and safe scale-up to industrial levels and superior results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Sodium Ibandronate Propylene Glycolate from 3-(N-Methyl-N-Pentylamino)Propanoic Acid Hydrochloride

[0031]3-(N-Methyl-N-pentylamino)propanoic acid hydrochloride (100 g) was suspended in toluene (300 mL) and polyethylene glycol 400 (120 mL). Phosphorous acid (43.01 g 1.1 eq.) was added to the mixture. The mixture was warmed and phosphorous trichloride (98.22 g, 1.5 eq.) was added at a rate such that the temperature remained below 60° C. The mixture was stirred for 10 hours at 55-60° C. whereupon it was quenched by adding water (450 mL). The water addition was controlled to maintain a reaction temperature below 70° C. The layers were separated and the aqueous layer was refluxed for 6 hours. The mixture was cooled to 40-45° C. to provide Ibandronic acid in solution and the pH was adjusted to 4.3-4.5 using 50% aqueous sodium hydroxide. Propylene glycol (150 mL) was then added to the reaction mixture at 60-65° C. and stirred for 4-5 hours. The mixture was cooled to 20-25° C....

example 2

Preparation of Sodium Ibandronate Propylene Glycolate from Ibandronic Acid

[0039]Ibandronic acid (6.30 g, 19.7 mmol) was suspended in water (18.0 mL) and heated to dissolution (42° C.). The pH was adjusted to 4.4 using 50% aqueous sodium hydroxide. 1,2-Propanediol was added to the reaction mixture at 56° C. and the mixture was stirred for 2.5 hours. The mixture was cooled to 20-25° C. over a period of 2.5 hours and stirred for another 15 hours. The mixture was filtered, washed with ethyl acetate (2 ×10 mL). The damp solid was suspended in 30 mL of ethyl acetate and stirred at 20-25 ° C. for 1 hour, filtered, rinsed with ethyl acetate (2×10 mL) and dried in vacuo at 65° C. for 8 hours to yield sodium Ibandronate propylene glycolate (4.54 g).

example 3

Preparation of Sodium Ibandronate R-Propylene Glycolate by Recrystallization

[0040]Sodium Ibandronate (2.0 g) was suspended in 6 mL (3.0 vol) of water in a round bottom flask. The flask was heated to dissolution (55-65° C.) at which point 2 mL R-propylene glycol (1.0 vol) was added to the flask. The temperature of the flask was held at 60-65° C. for 2 hours, then cooled to 20-25° C. and held at this temperature for 0.5 hours. Acetone (4 mL, 2.0 vol) was added and the flask was stirred at 20-25° C. for 0.5 hours. The precipitated solid was isolated by filtration, rinsed with acetone and dried in a vacuum oven at 60-65° C. This provided 1.97 grams of Ibandronate sodium R-propylene glycolate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com